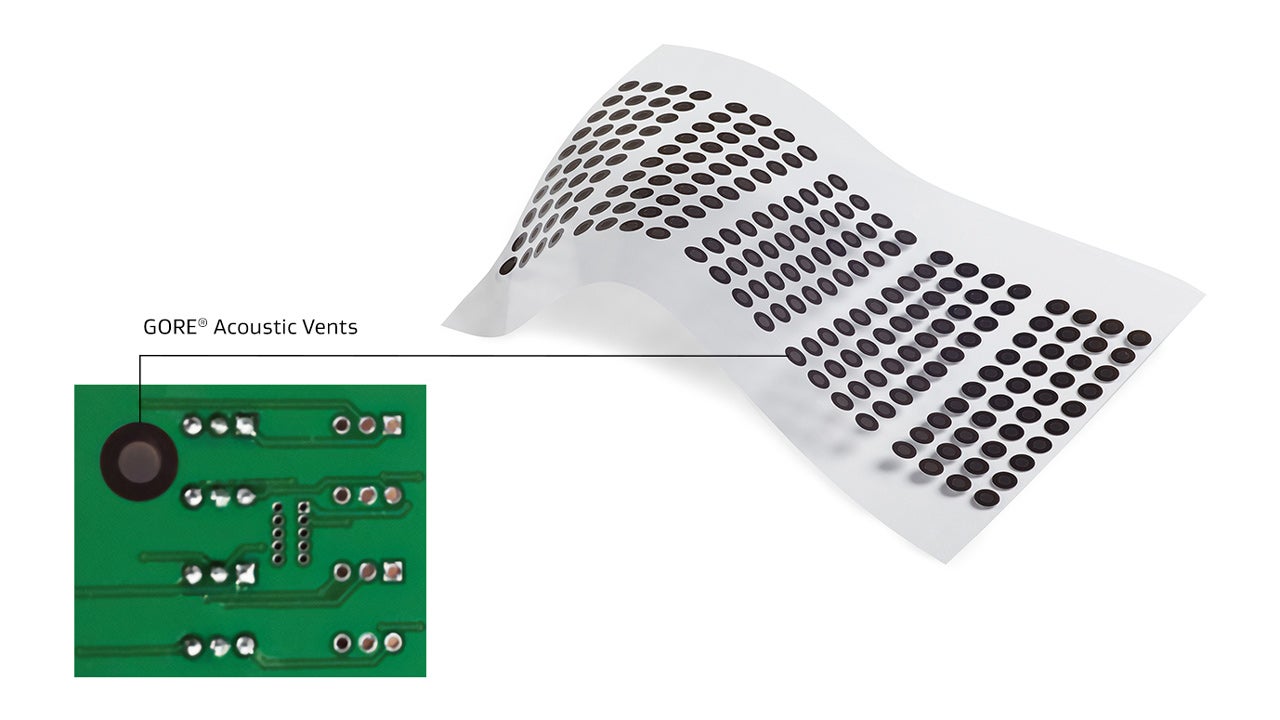

GORE® Acoustic Vents for Industrial Applications

More effective protection from outdoor challenges enables more reliable performance and enhanced sound quality of industrial acoustic devices.

Reliable Acoustic Protection for MEMS Microphones & Speakers

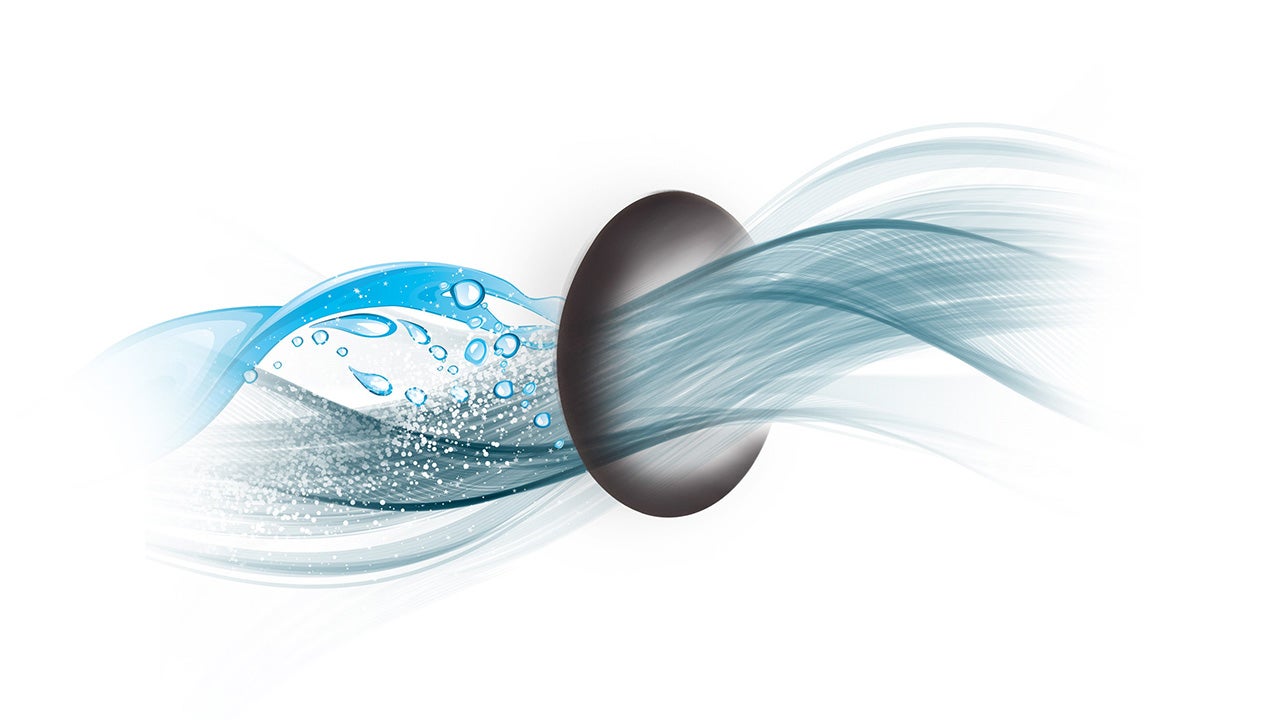

GORE® Acoustic Vents are engineered to protect sensitive electronics while preserving sound quality. They equalize pressure, manage condensation, and simplify housing design—reducing weight, complexity, and cost. At the same time, they block moisture and contaminants to extend device life and ensure reliable acoustic performance - even in the harshest conditions.

Technical Information

For Microphones in Industrial Applications

The same apertures that enable microphone sound transmission also can make it easy for liquids and particles to enter and degrade both acoustic quality and device reliability. Gore offers a range of industrial acoustic vents designed to protect against these threats:

For Splash & Dust Protection | ||

|---|---|---|

Series 234 | ||

P/N | ID [mm] | OD [mm] |

AVP2341.53.5 | 1.5 | 3.5 |

AVP2342.04.0 | 2.0 | 4.0 |

AVP2342.55.0 | 2.5 | 5.0 |

AVP2343.06.0 | 3.0 | 6.0 |

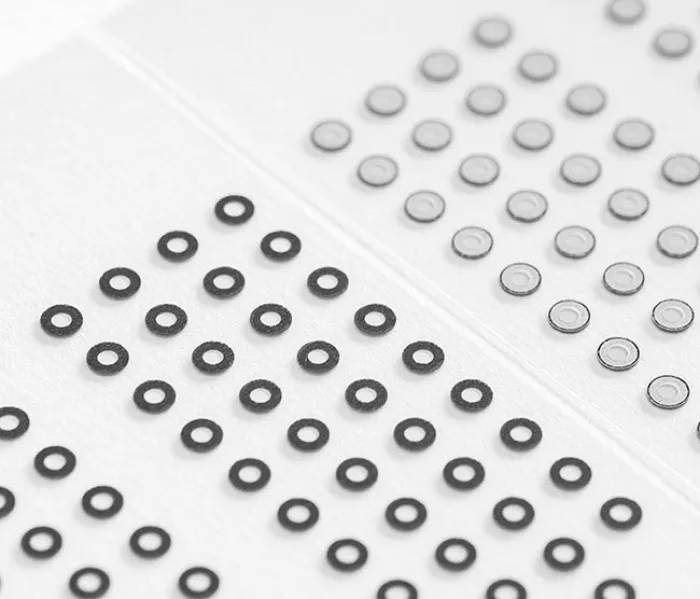

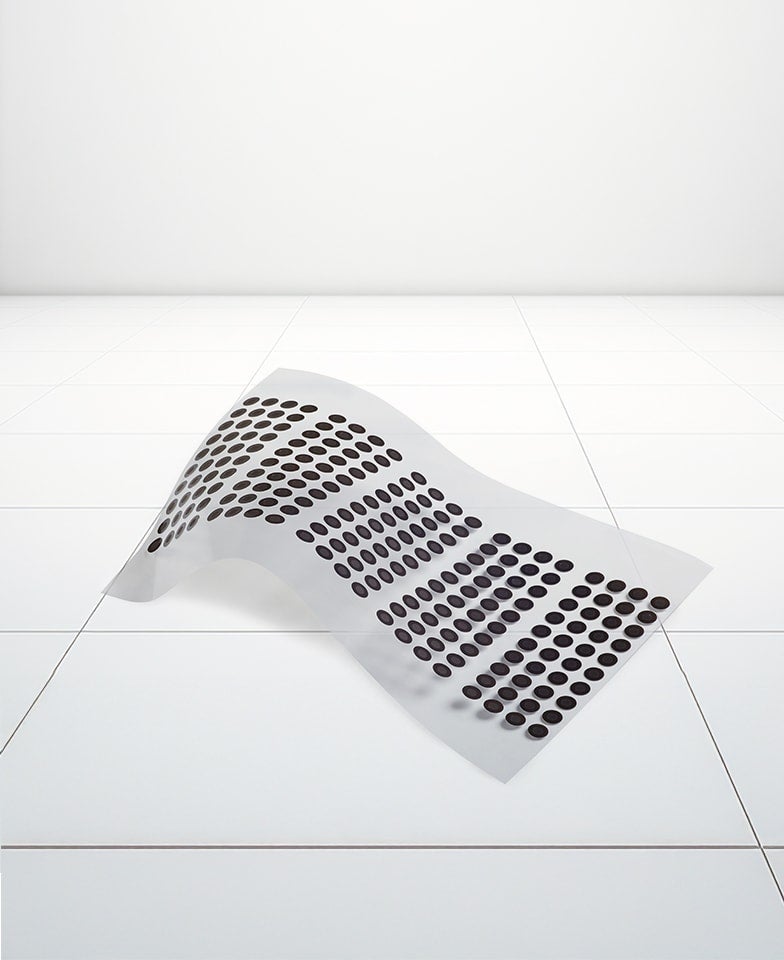

Packaging: Supplied on sheets | ||

For Superior Fluids & Dust Protection | ||

|---|---|---|

Series 434 | ||

P/N | ID [mm] | OD [mm |

AVP4341.53.5 | 1.5 | 3.5 |

AVP4342.04.0 | 2.0 | 4.0 |

AVP4342.55.0 | 2.5 | 5.0 |

AVP4343.06.0 | 3.0 | 6.0 |

Packaging: Supplied on sheets | ||

For Speakers & Receivers in Industrial Applications

With their larger apertures, speakers and receivers can be more vulnerable to ingress of fluids and contaminants. The device’s magnets may also attract metal particles that can accumulate and degrade sound quality. Gore offers a range of industrial acoustic vents designed to protect against these threats:

For Splash & Dust Protection | |||

|---|---|---|---|

Series 212 | |||

P/N | ID [mm] | OD [mm] | Parts across carrier |

AVP2120713 | 6.5 | 13.0 | 8 |

AVP2120919 | 9.0 | 19.0 | 6 |

AVP2121325 | 13.0 | 25.0 | 4 |

AVP2122029 | 20.0 | 29.0 | 4 |

Packaging: Supplied on rolls | |||

For Superior Fluids & Dust Protection | |||

|---|---|---|---|

Series 412 | |||

P/N | ID [mm] | OD [mm | Parts across carrier |

AVP4120713 | 6.5 | 13.0 | 8 |

AVP4120919 | 9.0 | 19.0 | 6 |

AVP4121325 | 13.0 | 25.0 | 4 |

AVP4122029 | 20.0 | 29.0 | 4 |

Packaging: Supplied on rolls | |||

Gore monitors and strives to comply with all regulations applicable to our products.

We have worked with our suppliers to eliminate PFOA from our supply chain. Our products meet EU REACH regulations EU 1907/2006 and EU 2019/2021.

GORE Protective Vents can help your outdoor electronic equipment enclosures meet IP enclosure and vented NEMA enclosure protection standards.

Featured Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.