GORE® LOW DRAG Filter Bags

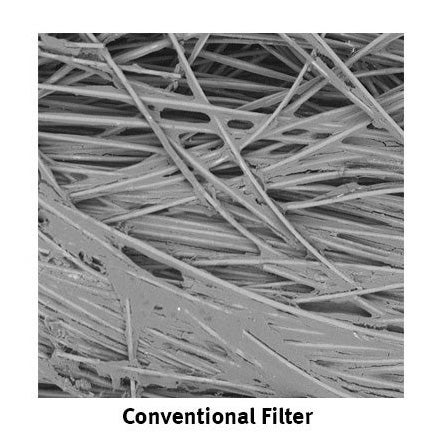

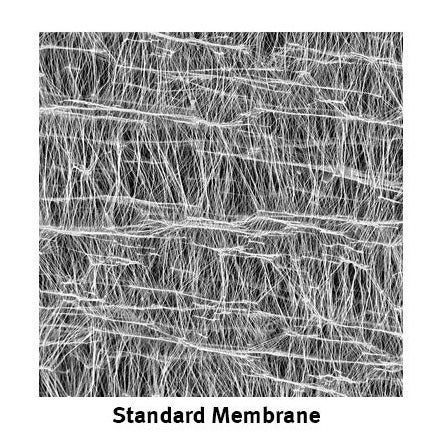

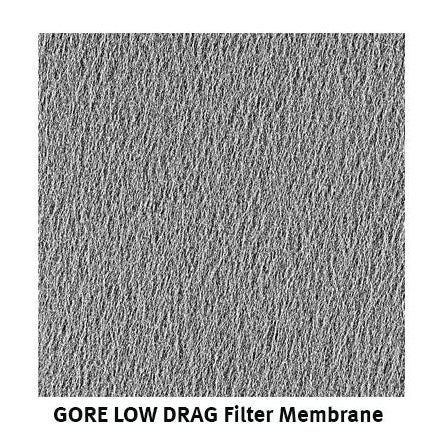

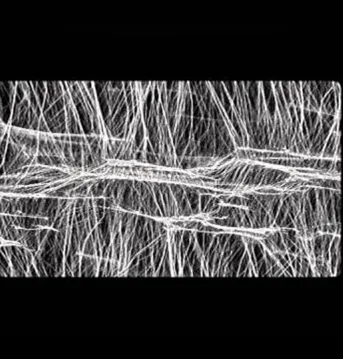

A step change in industrial dry filtration: An entirely new class of membranes developed by Gore acts as a true surface filter in fume and fine powder applications.

A Game Changer to the Industrial Fabric Filter Industry

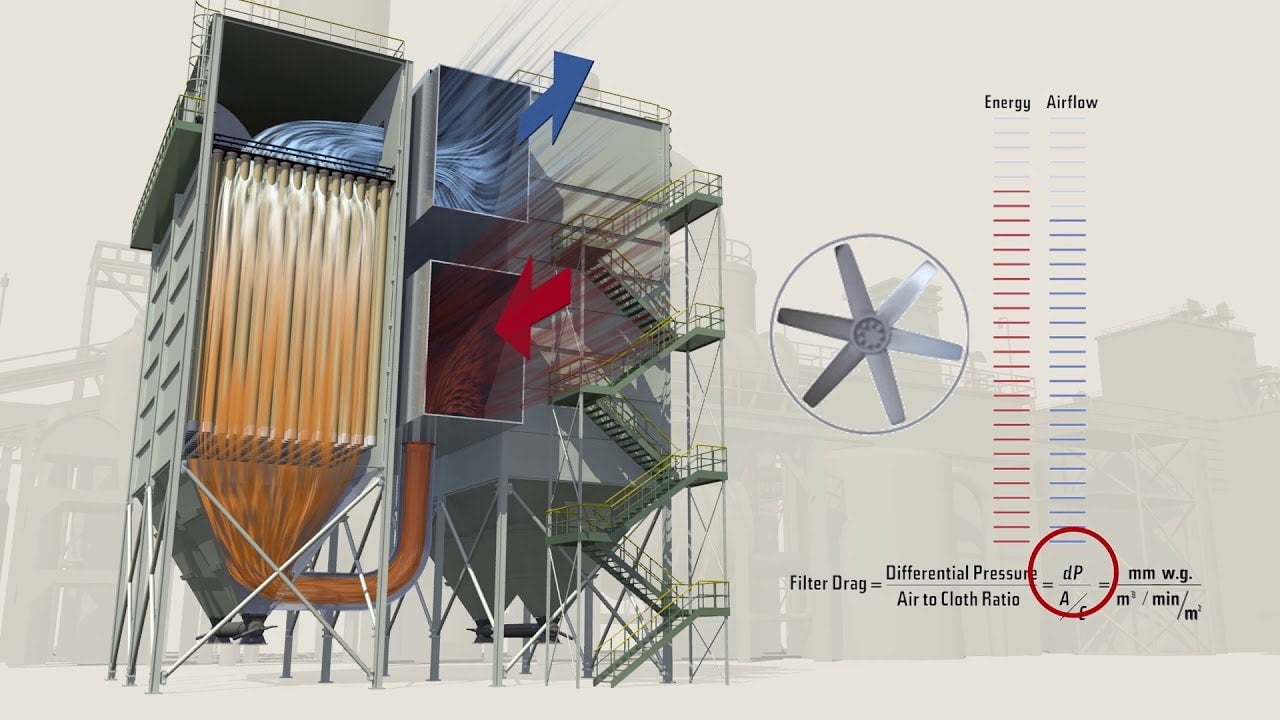

GORE® LOW DRAG Filter Bags provide a fundamentally more cleanable surface resulting in lower baghouse differential pressure. This can lead to either higher airflow during operation or a reduction in fan energy consumption. The bags improve particulate capture efficiency, leading to lower emissions overall. And with their longer effective bag life, our bags result in reduced cost of ownership.

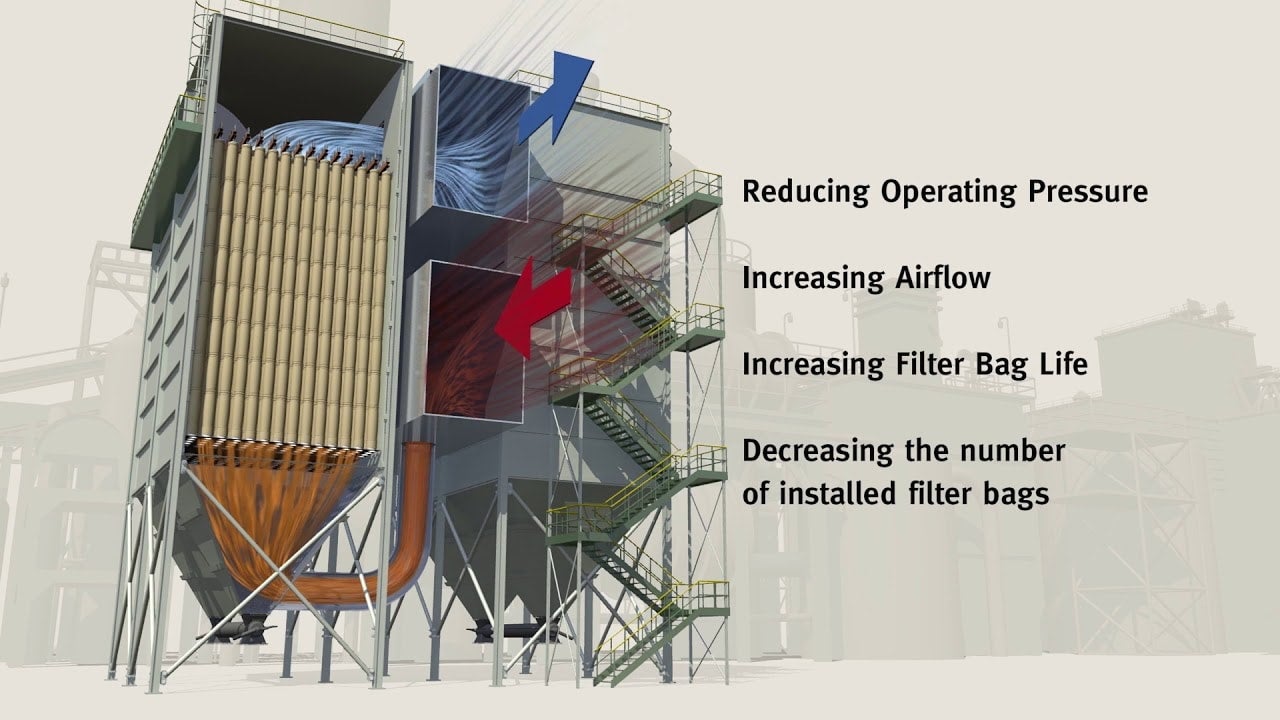

Reverse Air Baghouse Optimization

Learn how GORE LOW DRAG Filter Bags improve your overall operation of air pollution control systems in metallurgical processing operations.

Pulse-jet Baghouse Optimization

See how GORE LOW DRAG Filter Bags help increase your airflow and productivity while saving costs and reducing emissions.

Technical Information

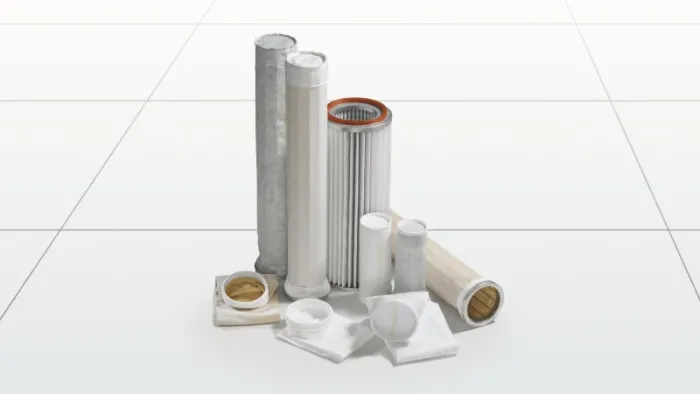

We offer a number of different membrane filter media, each with different performance capabilities and price, and can design each to fit your application.

GORE LOW DRAG Filter Bag - Polyester Felt - 4470

A 135 °C (275 °F) maximum service temperature, polyester felt with GORE LOW DRAG Filter Bag membrane for use in pulse jet style dust collectors.

GORE LOW DRAG Filter Bag - 10 oz fiberglass - 3170

A long lasting, acid-resistant fiberglass fabric filter bag with the latest GORE LOW DRAG filter technology for reverse air style dust collectors; enables operation in high temperature environments (260 °C, 500 °F).

GORE LOW DRAG Filter Bag - 22 oz fiberglass - 3670

This PTFE coated fiberglass GORE LOW DRAG Filter Bag is the latest technology for pulse jet style dust collectors, enabling operation in high temperature environments (260 °C, 500 °F).

GORE LOW DRAG Filter Bag - PTFE fabric - 8170

A 260 °C (500 °F ) maximum service temperature, PTFE fabric for use in pulse jet, reverse air, and shaker style dust collectors with chemically aggressive operating conditions.

GORE LOW DRAG Filter Bag - PTFE felt - 8378

A 260 °C (500 °F) maximum service temperature, expanded PTFE felt filter bag for use in pulse jet style dust collectors with chemically aggressive operating conditions.

Featured Content

Related Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 231 4364

Have questions or unique requirements?

Our experts are here to guide you.