GORE® Gasket Tape Series 1000 for Glass Lined Steel Flanges

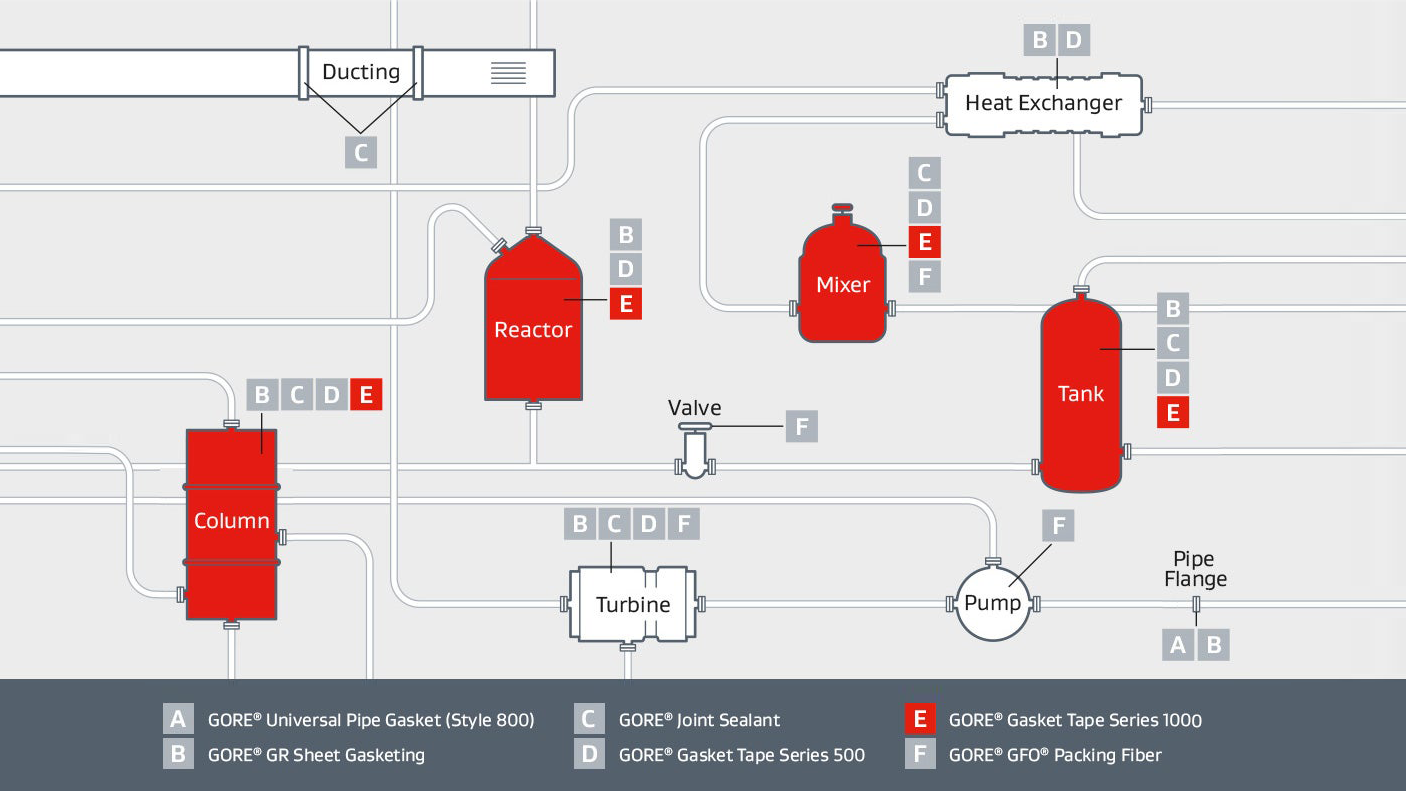

Easily and reliably seal glass-lined steel to contain aggressive media, protect equipment, and reduce emissions.

Reliable sealing for glass-lined steel piping and equipment

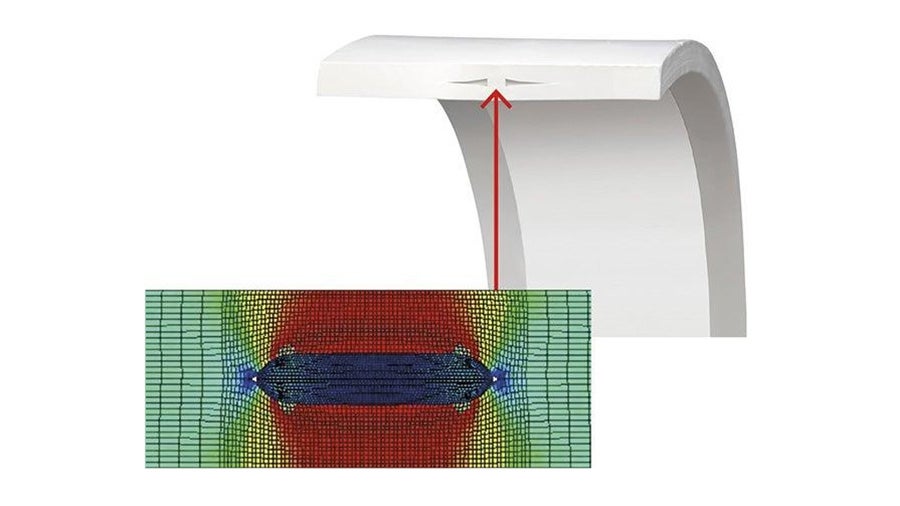

Chemical processors use glass-lined steel pipe and equipment to deal with aggressive media under demanding conditions. Yet the inherent demands of such systems can make it challenging to maintain a tight, lasting seal and prevent leaks that can pose hazards to the equipment, and to the working environment. GORE® Gasket Tape Series 1000 addresses these challenges:

- High temperatures

- Alternating system pressures

- Limited gasket loads

- Deviations in flanges / sealing surfaces

Expanded PTFE Tape

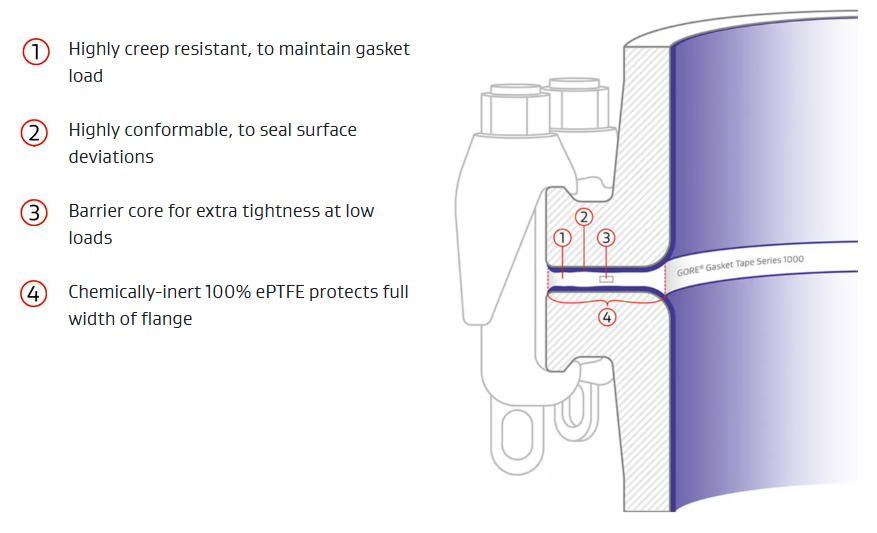

Made of 100% expanded PTFE (ePTFE), GORE Gasket Tape 1000 is a highly conformable sealant tape is chemically inert, and highly resistant to creep, cold flow and clamp-force loss. Its proprietary barrier core maintains an extra-tight seal even at low loads.

Comparison with Competitive Products

Aggressive media can cause common envelope gaskets to degrade or fail, creating risks for personnel and potential for equipment/corrosion damage, production downtime and related costs.

Large Envelope Gaskets | GORE Gasket Tape Series 1000 |

|---|---|

Material mix doesn’t offer overall chemical resistance: Microcracks on the PTFE envelope will allow diffusion which can destroy the inner core | Provides chemical protection across the full flange width (100% ePTFE) |

Limited seal reliability/durability over time and process cycles can require more frequent maintenance and downtime. | Exceptional creep resistance enables longer maintenance cycles, as demanded by leading chemical producers. |

Limited conformability to flange deviations. May complicate mechanical completion or delay start-up. | Outstanding conformability to deviations enables reliable sealing even at low gasket stress. Easily passes the bubble test, for trouble-free mechanical completion (MC) or start-up. |

Typically fabricated off-site, with long lead times. | Customize gasket on-site — no fabrication lead-time. |

Time-consuming/complex installation procedures. | Easy handling, and adhesive backing enables easy installation. Faster, less complicated shimming tape solution for larger flange deviations. |

Related supply-chain challenges (availability, shipping/logistics complications). | Assured supply; simplifies and speeds transport and handling. |

Inventory costs and issues. | Reduces inventory carrying costs. |

GORE Gasket Tape Series 1000 Outperforms other ePTFE tapes

Other ePTFE Gaskets | GORE Gasket Tape Series 1000 |

|---|---|

Limited seal tightness especially at low stress. | Seals more than 10 times tighter than other ePTFE gasket tapes. |

Gaskets’ limited durability may require glass-lined steel equipment at less than full specification range. | Allows full use of entire specification range of the glass-lined steel equipment. |

Requires shimming even at lower deviations. May complicate mechanical completion or delay start-up. | Outstanding conformability to deviations enables reliable sealing even at low gasket stress. Easily passes the bubble test, for trouble-free mechanical completion (MC) or start-up. |

Limited seal reliability/durability over time and process cycles can require more frequent maintenance and downtime. | Exceptional creep resistance enables longer maintenance cycles, as demanded by leading chemical producers. |

GORE Gasket Tape Series 1000 Outperforms Filled PTFE Gaskets

Filled ePTFE Gaskets | GORE Gasket Tape Series 1000 |

|---|---|

Typically fabricated off-site, with long lead times. | Customize gasket on-site — no fabrication lead-time. |

Related supply-chain challenges (availability, shipping/logistics complications). | Assured supply; simplifies and speeds transport and handling. |

May be dovetailed for easier transport, which can result in emissions through the non-overlapping dovetail joints. | Product supplied on a convenient spool. Installs using skived joints to maintain a tight, reliable seal. |

Inventory costs and issues. | Reduces inventory carrying costs. |

Time-consuming/complex installation procedures. | Easy handling and adhesive backing enables easy installation. Faster, less complicated shimming tape solution for larger flange deviations. |

Limited conformability to flange deviations. May complicate mechanical completion (MC) or delay start-up. | Outstanding conformability to deviations enables reliable sealing even at low gasket stress. Easily passes the bubble test, for trouble-free mechanical completion (MC) or start-up. |

Limited seal reliability/durability over time and process cycles can require more frequent maintenance and downtime. | Exceptional creep resistance enables longer maintenance cycles, as demanded by leading chemical producers. |

Technical Information

Material | •100% expanded PTFE (polytetrafluoroethylene), with multidirectional strength •This product is supplied with an adhesive backer only to aid in the product installation |

Chemical Resistance | Chemical resistance to all media pH 0-14, except molten alkali metals and elemental fluorine. Chemical resistance to all media pH 0-14, except molten alkali metals and elemental fluorine. |

Operating Range | The maximum applicable pressure and temperature depend mainly on the equipment and installation. •Typical Use: from -60 °C to 230 °C (-76 °F to 445 °F); •Maximum Use: -269 °C to 315 °C (-452 °F to 600 °F);

For applications outside the typical use range, Gore recommends an application specific engineering design calculation and extra care during installation. |

Shelf Life | Expanded PTFE is not subject to aging and can be stored indefinitely. To ensure optimal adhesive function, we recommend use within two years of date of purchase when stored under normal(2) conditions |

(1) absolute pressure of 1 mmHg (Torr) = 133 Pa = 1.33 mbar = 0.019 psi

(2) 21 °C (70 °F) 50% Relative Humidity

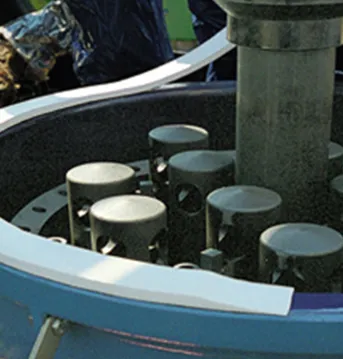

GORE® Gasket Tape Series 1000 is manufactured to metric dimensions. Choose from multiple widths, thicknesses and lengths, in any combination.

Width | Thickness | Length |

40 mm (1.5") | 6 mm (1/4") | 5 m (16') |

55 mm (2") | 9 mm (3/8") | 10 m (32') |

65 mm (2.5") |

| 15 m (49') |

- Select a tape width that is the same as, or wider than, your flange width.

- Select 6 mm thickness for deviations up to 1.7 mm (0.07”) without shimming.

- Select 9 mm thickness for deviations up to 2.5 mm (0.10”) without shimming.

- For larger deviations, consider adding Gore Series 1000 Shimming Tape.

Gore Series 1000 Shimming Tape is 3 mm (1/8") thick and 5 m (16') long, in any of the above widths. Select shimming tape to the same width as your Series 1000 gasket tape.

Test Data

| Thickness | Thickness |

PQR, 150 °C (302 °F) | 0.49 | 0.41 |

PQR, 230 °C (445 °F) | 0.36 | 0.29 |

Based on EN 13555 creep relaxation test protocol (PQR).

This testing was conducted with a fixture stiffness of 500 kN/mm, with 2 stripes of 250 mm x 55 mm with a starting stress of 10 MPa.

| Thickness | Thickness |

Qmin (0.1) | 9 MPa | 13 MPa |

Qmin (0.01) | 14 MPa | 18 MPa |

Qsmin up to L0.0001 and QA > 5 MPa | 5 MPa | 5 MPa |

m | 5 | 5 |

y | 9 MPa | 13 MPa |

Based on EN 13555 leakage test protocol. DN 200 PN 10 plattens, 10 bar nitrogen, 30 mm wide tape.

| Thickness | Thickness |

Stress to seal 0.1 mg/(m•s) measured on | 9 MPa | 13 MPa |

Stress to seal 0.01 mg/(m•s) measured on | 14 MPa | 18 MPa |

Based on EN 13555 leakage test protocol. DN 200 PN 10 plattens, with 0.5 mm deep groove with sloped edges cut into the plattens, 10 bar nitrogen, 30 mm wide tape.

| Thickness | Thickness |

Max. surface stress at 23 °C (73 °F) | 70 MPa | 70 MPa |

2 x 250 mm x 55 mm strips, 500 kN/mm, 0.1 MPa/s load rate, 15 min hold time, no visible damage.

Certificates & Application Information

| Type | Description | File |

|---|---|---|

| TA Luft | For the TA Luft1 test, the seal is installed in a DN40/PN40 steel flange, usually with a gasket stress of 30 MPa. The flange is then exposed to a defined temperature for minimum 48 hours. After cool down, leakage rate is measured over a period of at least 24 hours. The test pressure is 1 bar helium. TA Luft certificates are available for thicknesses 6 mm. 1Federal Ministry of Germany for the Environment, Nature Conservation, Building and Nuclear Safety: First General Administrative Regulation Pertaining the Federal Emission Control Act (Technical Instructions on Air Quality Control - TA Luft), Joint Ministerial Gazette, July 30, 2012. | Download PDF |

| Safety Information | GORE® Gasketing products meet the definition of an article; therefore, a Material Safety Data Sheet (MSDS) or Safety Data Sheet (SDS) is not required. However, for your convenience, a Product Safety Sheet (PSS), which details the intended use and proper handling of our articles, is provided below. | Download PDF |

| Gore Quality Management System | The Gore Sealant Technologies Quality Management System is certified in accordance with ISO 9001. |

Related Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 542 3146

Have questions or unique requirements?

Our experts are here to guide you.