GORE® Insulated Wires for Oil and Gas Downhole Equipment

GORE® Insulated Wires deliver failure-free performance and protection in a smaller, more durable package extending equipment life in harsh environments.

Unsurpassed Performance in Harsh Conditions

Constructed with uniquely engineered fluoropolymers, our insulated wires are designed to withstand extreme oil and gas downhole environments. They provide superior mechanical protection against harsh chemicals and hydrolysis in high temperatures, and withstanding repeated mechanical stress caused by deep drilling. GORE Insulated Wires also deliver outstanding electrical performance with dependable signal integrity.

Technical Information

Gore's tests were modified to achieve better accuracy in comparing GORE Insulated Wires to conventional PTFE and PTFE-PI-PTFE wire insulation. Results are based on bare copper wires insulated with 6-millimeter wall insulation material. Results for tensile strength and dielectric constant are based on film material.

| Test Method | GORE Insulated Wires | Conventional PTFE Insulated Wires | PTFE-PI-PTFE Insulated Wires | |

|---|---|---|---|---|

| Tensile Strength (psi/MPa) | Gore test based on ASTM D88312 | 39,530 psi 272.55 MPa | 2,253psi 15.5 MPa | 17,589 psi 121.27 MPa |

| Dielectric Constant @ 23°C (73°F) | ASTMD150 | 2.1 | 2.1 | 2.85 |

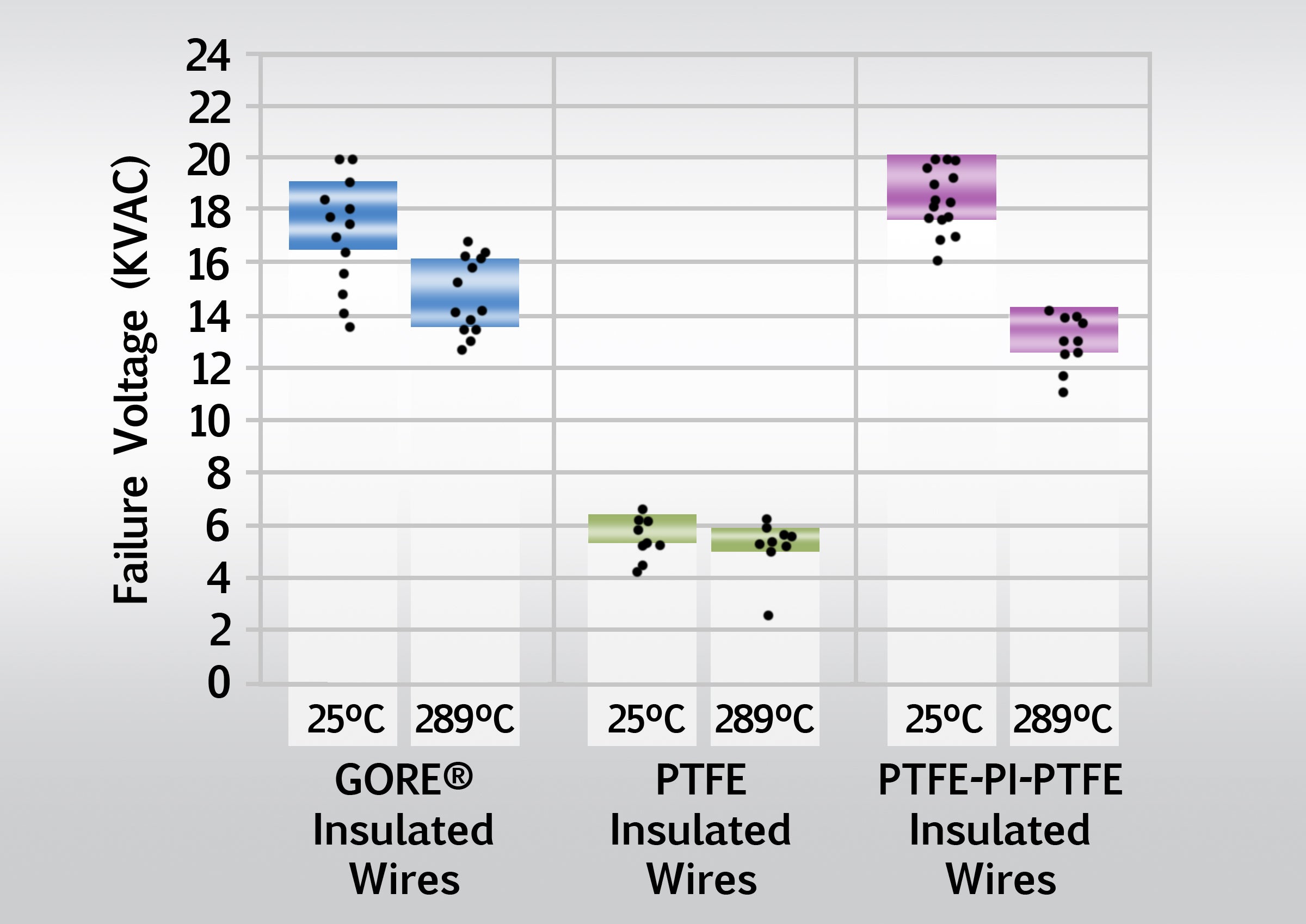

| Dielectric Breakdown Voltage @ 23°C (73°F) | Gore test based on NEMA MW 1000,3.8.2 | 17 kVAC | 5.8 kVAC | 18.2 kVAC |

| Dielectric Breakdown Voltage @ 289°C (552°F) | Gore test based on NEMA MW 1000,3.8.2 | 14.5 kVAC | 4.9 kVAC | 13.2 kVAC |

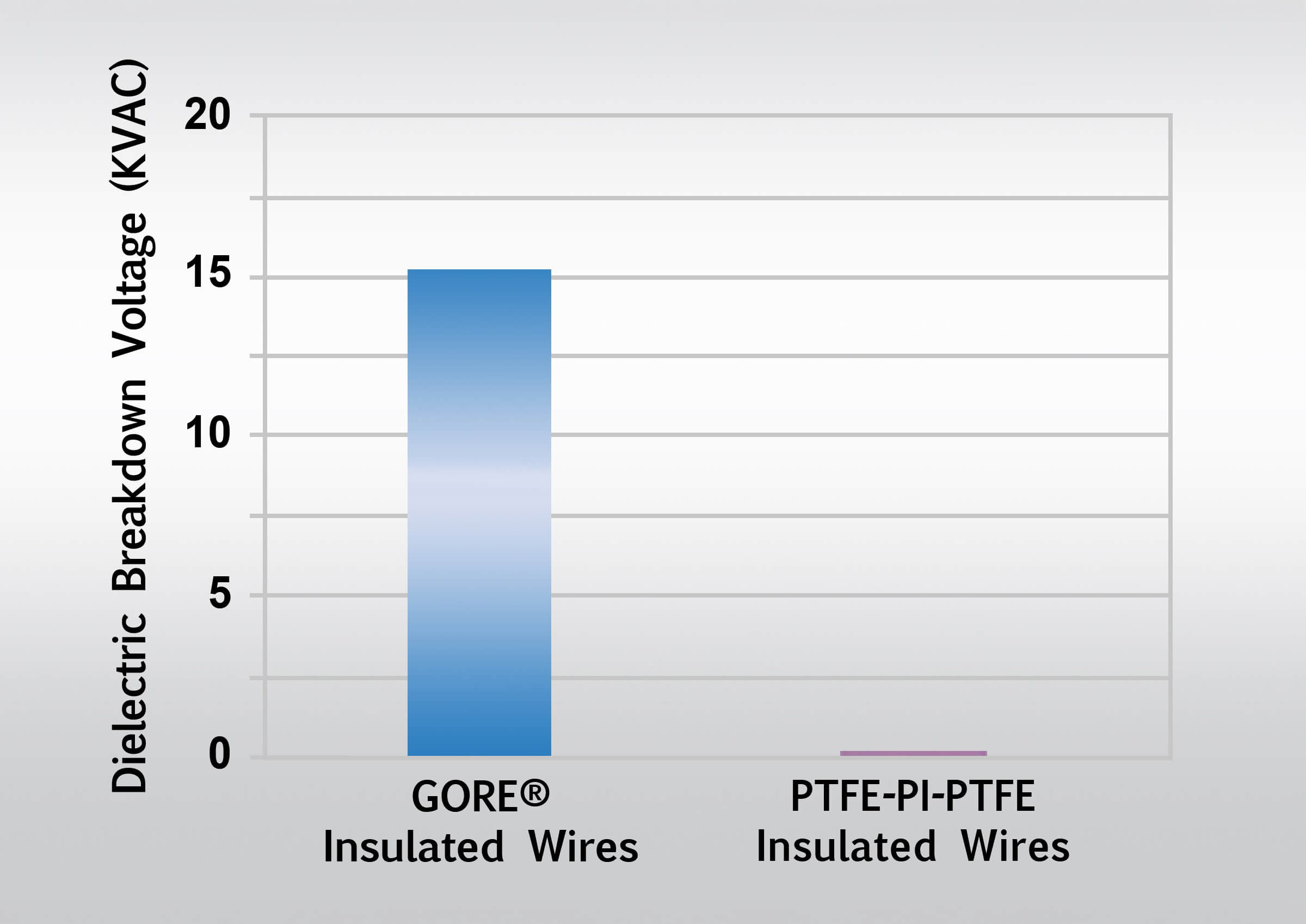

| Dielectric Breakdown Voltage after 1500 hrs exposure to Hydrolysis @ 98°C (208°F) | Gore test based on NEMA MW 1000,3.8.2 | 15.4 kVAC | Not Tested | 0 kVAC |

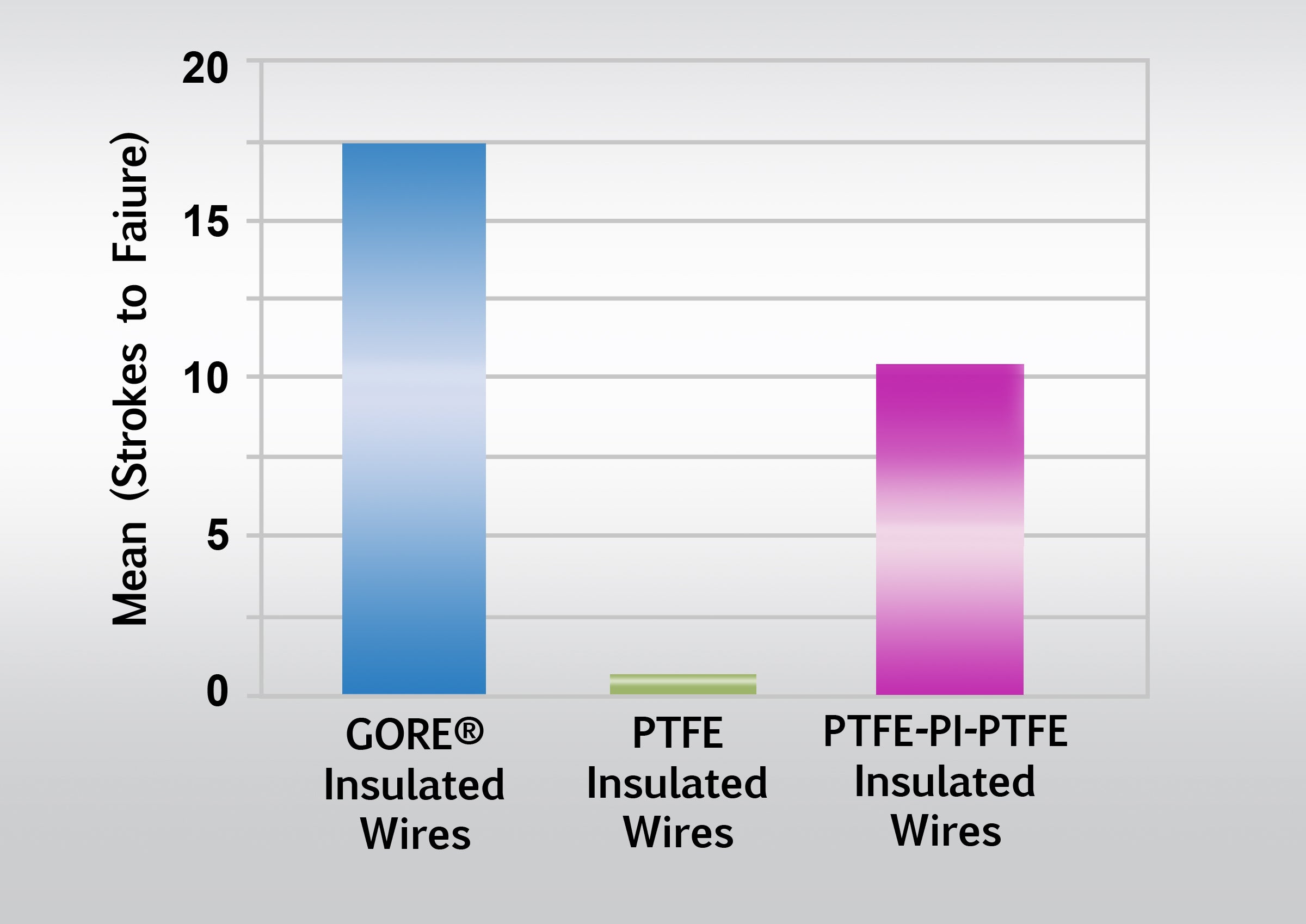

| Scrape Abrasion | Gore test based on ASTM D1676, Sec.17 | 17.6 cycles | 0.7 cycles | 10.4 cycles |

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 866 271 5954

Have questions or unique requirements?

Our experts are here to guide you.