GORE® Magnet Wire for Oil & Gas Downhole Motors

Extend motor life, increase tool reliability and minimize the risk of unexpected failures with our durable, robust magnet wire.

Longer Motor Life, Increased Tool Reliability, Maximum Voltage Endurance

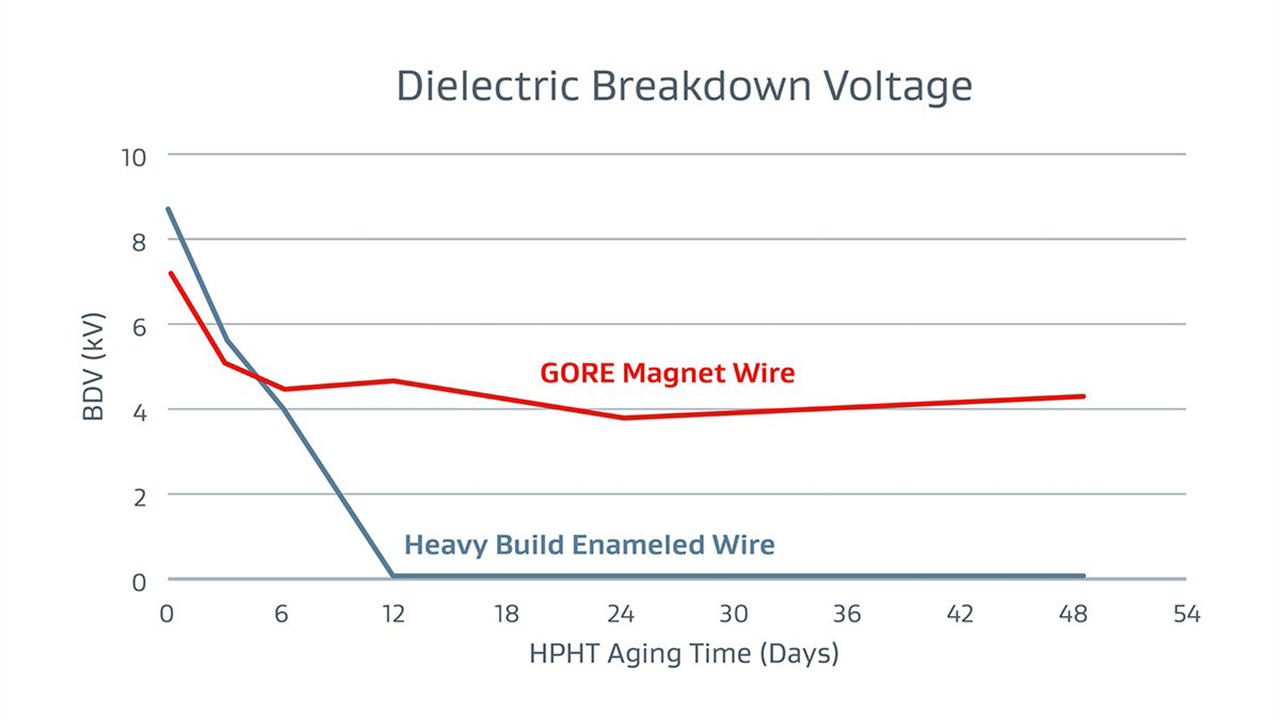

With exceptional resistance to extreme downhole conditions, GORE® Magnet Wires are proven to maintain the highest voltage endurance, unmatched by traditional heavy build enameled wires. Our wires have a unique engineered fluoropolymer insulation that’s resistant to difficult conditions like chemicals, hydrolysis, and up to high pressure, high temperature (HPHT) environments.

Technical Information

These values demonstrate the electrical, mechanical and environmental performance of GORE Magnet Wire.

| Property | Value |

|---|---|

| Operating Voltage Range (V) AC | 300 — 600 |

| Spark Test Voltage (V) AC | 1500 |

| Dielectric Breakdown Voltage (kV) tested per ANSI/NEMA MW 1000a | 4.4 |

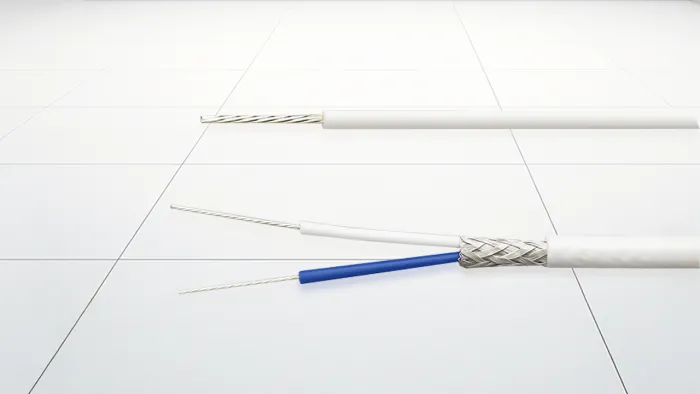

| Wire Insulation | Engineered Fluoropolymer |

| Conductor | Bare Copper |

| Operating Temperature Range (°C) | -55 to +260 |

| RoHS | Compliant |

a Testing based on size AWG 2801

GSC-33-61112-00

GSC-33-61164-00

GSC-33-61186-00

GSC-33-61187-00

GSC-33-61201-00

GSC-33-61203-00

GSC-33-61205-00

GSC-33-61207-00

GSC-33-61209-00

GSC-33-61213-00

GSC-33-61223-00

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 866 271 5954

Have questions or unique requirements?

Our experts are here to guide you.