Lithography Equipment

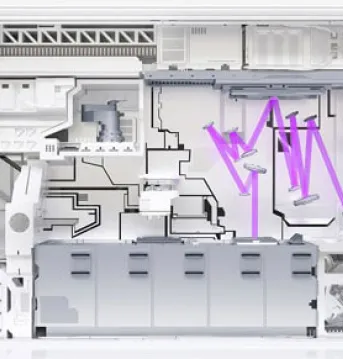

Gore supports cutting-edge advances in semiconductor manufacturing with custom-configured cables that deliver reliable, ultra-clean performance in lithography and vacuum applications. Our solutions help reduce cable maintenance and downtime, lowering total costs over the equipment’s lifecycle.

Enabling Precision in Lithography

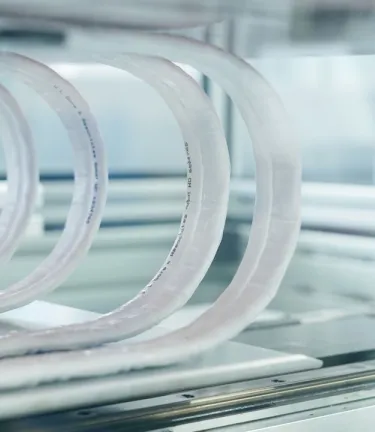

Gore collaborates with leading semiconductor manufactures to develop custom reliable cables for lithography systems operating in ultra-clean and ultra-high vacuum environments. Our in-depth knowledge, materials expertise, cleaning processes and rigorous quality testing bring innovative cable assemblies for lithography applications that help our customers keep pace with the industry’s constantly evolving demands.

Advancing Performance in High-Vacuum Environments

EUV (extreme ultraviolet) and DUV (deep ultraviolet) lithography processes demand exceptional precision, cleanliness, and reliability especially with next-gen technology like High Numerical Aperture (High NA EUV) lithography systems. Gore supports these technologies with high-performance static and high-flex cables engineered for high-vacuum environments. Qualified for Cleanliness Grades 1, 2, and 4, our cables deliver low outgassing, tight bendability, and durable signal integrity—helping improve throughput, reduce maintenance, and meet the industry's evolving performance standards.