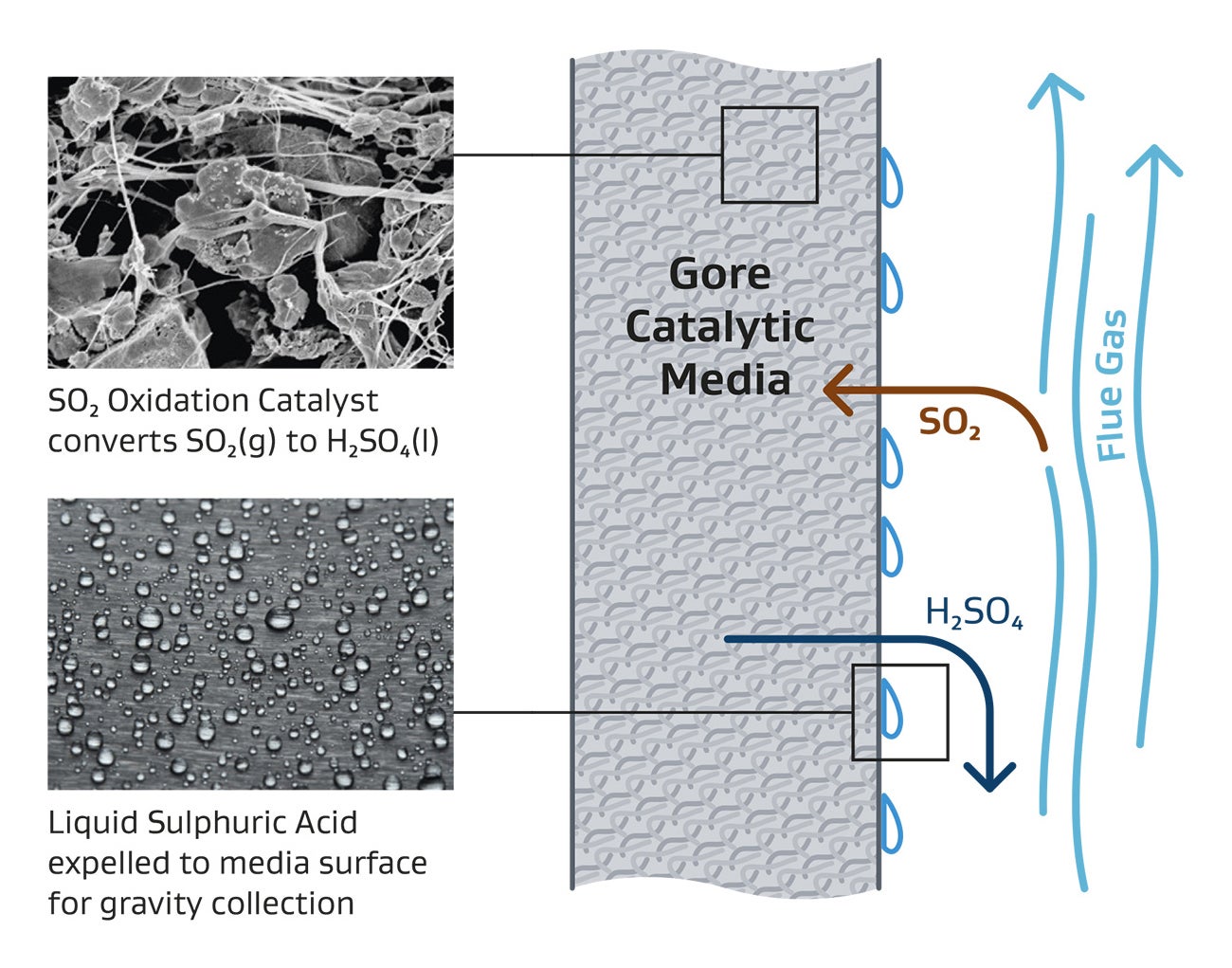

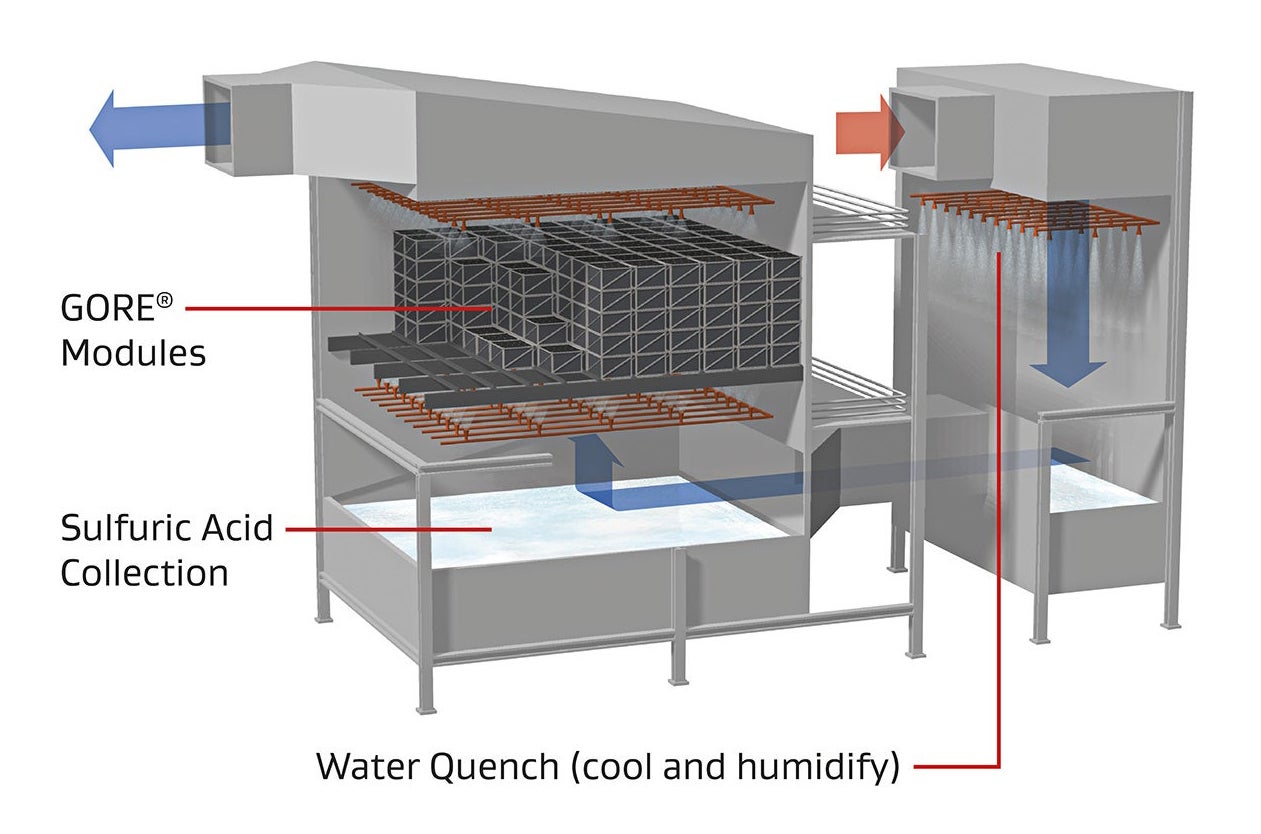

GORE SO2 Control System for Flue Gas Desulphurization (FGD)

The SO2 Control System is a reagent free flue gas desulphurisation (FGD) system with a small footprint and simple operation, resulting in low operating costs.

Reduce Emissions of SO2

The GORE SO2 Control System utilizes fixed catalysts to convert SO2 into saleable sulfuric acid, eliminating concerns related to reagent supply, logistics, handling, storage and preparation operations, reagent price volatility and solid waste disposal. It is installed after an existing ESP or baghouse, there is no impact on fly ash.

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 654 4229

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.