GORE® MEMS Protective Vents for Microphones

GORE® MEMS Protective Vents provide environmental protection and manufacturing efficiency while enabling in-process acoustic testing in the high-volume assembly of printed circuit boards.

Proven MEMS Microphone Environmental Protection

Gore’s unique venting products for microelectronics mechanical systems (MEMS) offer proven microphone protection by preventing particle contamination and pressure build-ups and allowing in-process acoustic testing, which helps prevent microphone failure during the manufacturing process. With our advanced materials technology, device OEMs can improve acoustic consistency, unlock operational efficiencies, and cut costs.

GORE® MEMS Protective Vents - Style 100 - Installation

GORE® MEMS Protective Vents - Style 200 - Installation

Technical Information

| Product Performance Characteristics * | |

|---|---|

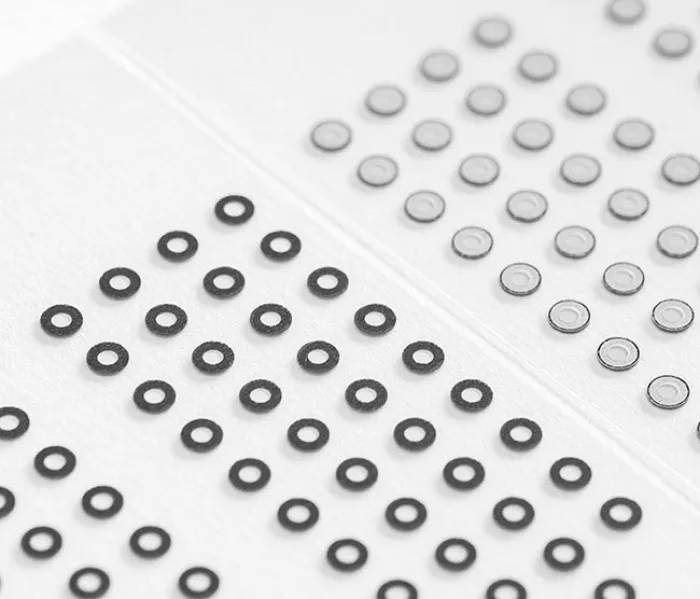

| Membrane Type | ePTFE |

| Membrane Characteristic | Hydrophobic |

| Membrane Color | White |

| Min. Airflow | 10 L/hr @70 mbar |

| Adhesive Type | Silicone based |

| Particle Retention | 100.00% @ 5 µm |

| Adhesive Temp. Resistance | Max. 260°C for 3 mins |

*Can be customized based on the specific needs of the application, data is generated based on typical value.

| Product Performance Characteristics * | |

|---|---|

| Membrane Type | ePTFE |

| Membrane Characteristic | Oleophobic |

| Membrane Color | White |

| Min. Airflow | 6 L/hr @ 12 mbar |

| Adhesive Temp. Resistance | Max. 280°C for 40 sec |

| Particle Retention | >99% @ 5 µm |

*Can be customized based on the specific needs of the application, data is generated based on typical value.

| Product Performance Characteristics* | |

|---|---|

| Membrane Type | ePTFE |

| Membrane Characteristic | Oleophobic |

| Membrane Color | White |

| Min. Airflow | 11.56 L/hr @ 70 mbar |

| Adhesive Temp. Resistance | Max. 280 °C for 40 sec |

| Particle Retention | > 90% @ 0.3 µm |

| Waterproof Capability | 2 meter @ 30 minutes |

*Can be customized based on the specific needs of the application, data is generated based on typical value.

Gore monitors and strives to comply with all regulations applicable to our products.

We have worked with our suppliers to eliminate PFOA from our supply chain. Our products meet EU REACH regulations EU 1907/2006 and EU 2019/1021.

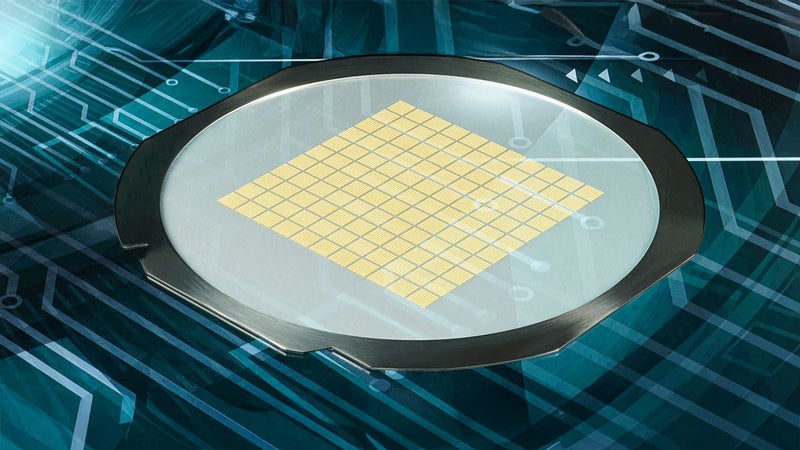

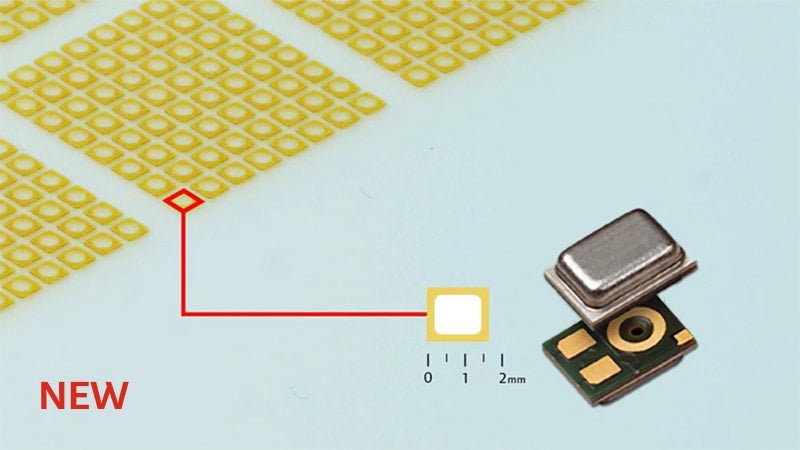

Style 100 — for circuit board assembly

Part number VP1001MPX

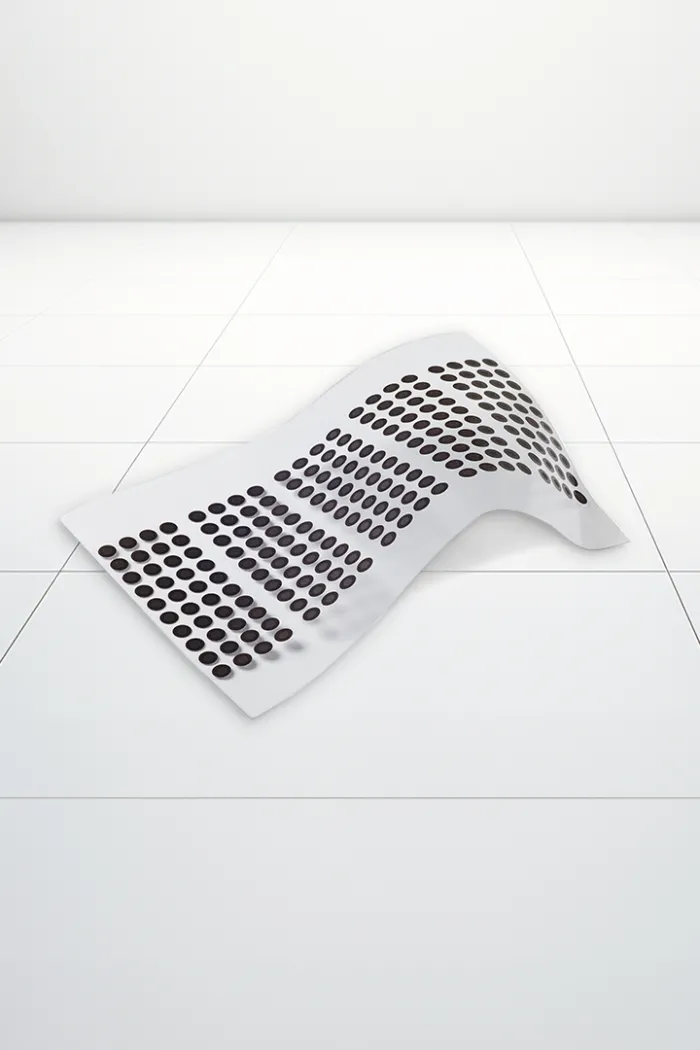

Style 200 - for microphone manufacturers

Part number VP0002MPN

Style 300

Part number VP0001MWN- for microphone manufacturers

Case Studies

Related Content

Testing for Ingress Protection of Portable Electronic Devices

Today’s consumers expect to be able to use their full-featured mobile devices anywhere...

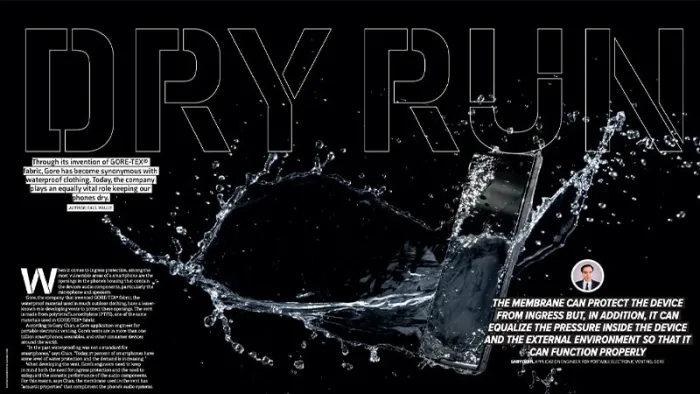

Consumer Electronics Test & Development Magazine: Dry Run - Protecting smartphones from water and other ingress

When it comes to ingress protection, among the most vulnerable areas of a smartphone...

A Proven Solution to Protect MEMS Microphones

Rigorous testing shows how GORE® MEMS Protective Vents Style 200 reliably prevents particle contamination...

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 410 506 7812

Have questions or unique requirements?

Our experts are here to guide you.