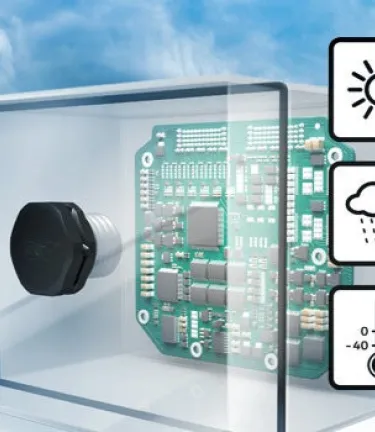

The Waterproof Performance of GORE® Protective Vents’ Membrane Technology Protects Outdoor Electronic Enclosures

Outdoor electronic enclosures are sealed for a very compelling reason: to keep out water or other fluids that could compromise the reliability or life-span of the electronic components inside. That’s why Gore’s oleophobic and waterproof vent membrane is the solution of choice. It blocks entry of liquids, and also equalizes pressure imbalances that could damage seals and create new leak paths.

It’s crucial for venting membranes to offer more than one kind of liquid-proof protection:

- A hydrophobic vent from Gore has a microporous structure with pores too small for water molecules to pass through. That’s how it keeps water from entering an electronic enclosure. Water has high surface tension, so it’s more likely to sit atop a vent membrane than to permeate (or “wet-out”) the membrane’s pores. An effective hydrophobic membrane allows enclosures to breathe and maintain a stable internal pressure, while preventing water in various forms (such as rain, sleet, fog, splashes or sprays) from entering the enclosure.

- An oleophobic vent from Gore includes hydrophobic protection, and also provides robust protection against ingress of oils and other low surface-tension fluids. This is important because low surface-tension fluids (such as detergents and cleaners, alcohols or fuels) could more easily permeate or “wet-out” a vent membrane and enter the enclosure. This level of added protection can be crucial for electronic enclosures in industrial, construction or agricultural applications, as well as commercial lighting and solar energy.

Let Us Help You Chose the Right Vent for Your Application.

What’s the solution?

The portfolio of GORE Protective Vents offers both hydrophobic, and hydrophobic + oleophobic vent membranes with a wide range of Ingress Protection (IP) ratings. The portfolio offers venting options for a wide range of applications that require waterproof outdoor enclosures: from tower-mounted telecom antenna enclosures to outdoor lighting enclosures that must block fog and all types of precipitation, to construction equipment that’s exposed to harsh weather, chemicals and fluids in the course of daily operation.

GORE Protective Vents Adhesive Series, Snap-In Series and Screw-In Series provide effective and lasting protection against ingress of water or other fluids, across the whole range of outdoor electronic enclosures and applications.

How GORE Vents Prevent Water Entry in Outdoor Electronic Enclosures

The GORE Membrane, of 100% ePTFE, is ideal for designers of waterproof enclosures who want hydrophobic protection that is “engineered in” to the membrane material itself, not an added-on coating. Additionally, GORE Membranes have high roll-off: they easily “shed” standing water drops to maintain their breathability, even after immersion. GORE Protective Vents can help vented weatherproof enclosures maintain their “sealed” status while also resolving dangerous pressure imbalances.

The GORE Membrane is also offered with additional oleophobic protection, for applications where a simple water-resistant enclosure is not enough. Waterproof enclosure design must also consider the need to withstand the presence of industrial or commercial cleaners, or common vehicular or machine oils. And of course, a truly weather-protective enclosure must also block ingress of other damaging contaminants, from dust and sandstorms, to smog particulates or insect infestations.

GORE Protective Vents are designed to provide broad-based ingress protection against water, fluids and particulates, and are available in a number of Ingress Protection (IP) ratings.

GORE Protective Vents Undergo Rigorous Testing to Resist Water Entry

All GORE Protective Vents for outdoor electronics have been fully tested by independent laboratories and are certified to withstand a wide range of environmental challenges. In particular, these vents reliably protect against ingress of liquids and particulates that could damage electronic components. Our portfolio of venting solutions offers the full range of Ingress Protection levels — including resistance to extended immersion — to meet different application needs.

| GORE® Protective Vents | Ingress Protection Testing | ||||||

|---|---|---|---|---|---|---|---|

IEC 60529 | ISO 20653 | ||||||

| IP64 | IP65 | IP66 | IP67 | IP68 2m/1hr | IP68 up to 72hr | IP69K | |

| Adhesive Series | |||||||

| VE8 | ✓ (I) | ✓ (I) | |||||

| VE7 | ✓ (I & E) | ✓ (E) | ✓ (E) | ✓ (I & E) | ✓ (I & E) | ||

| VE9 | ✓ (I & E) | ✓ (E) | ✓ (E) | ✓ (I & E) | ✓ (I & E) | ||

| Snap-In Series | |||||||

| GORE® PolyVent Hysi | ✓ | ✓ | ✓ | ✓ | |||

| GORE® PolyVent XS | ✓ | ✓ | ✓ | ✓ | ✓ | ✓* | |

| GORE® PolyVent Standard | ✓ | ✓ | ✓ | ✓ | ✓ | ✓* | |

| GORE® PolyVent High Airflow | ✓ | ✓ | ✓ | ✓ | ✓ | ✓* | |

| Screw-In Series | |||||||

| GORE® PolyVent XS | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| GORE® PolyVent Standard | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| GORE® PolyVent High Airflow | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| GORE® PolyVent XL | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| GORE® PolyVent Stainless Steel | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| GORE® PolyVent Ex+ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

(I) = Interior mounting only

(E) = Exterior mounting only

(I & E) = Interior or Exterior mounting

* Depending on housing geometry.

Learn more about protecting electronic components from water ingress in:

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.