Cables & Assemblies

Proven and trusted to withstand the harshest conditions in aerospace, land, automation and energy. Decades of reliability have made Gore’s products the top choice.

High-Performance Cable and Interconnect Solutions for Aerospace & Defense, Industrial, Semiconductor & Test

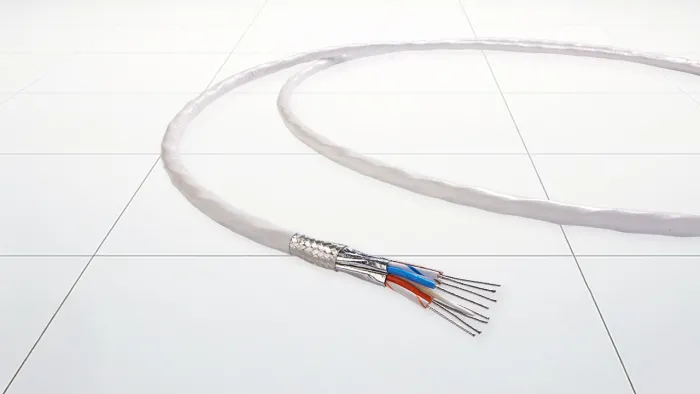

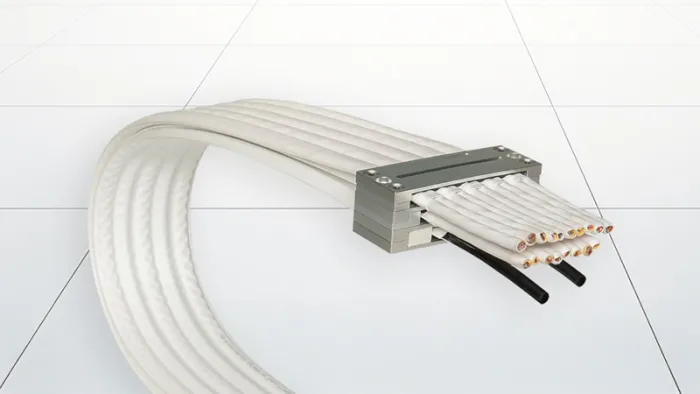

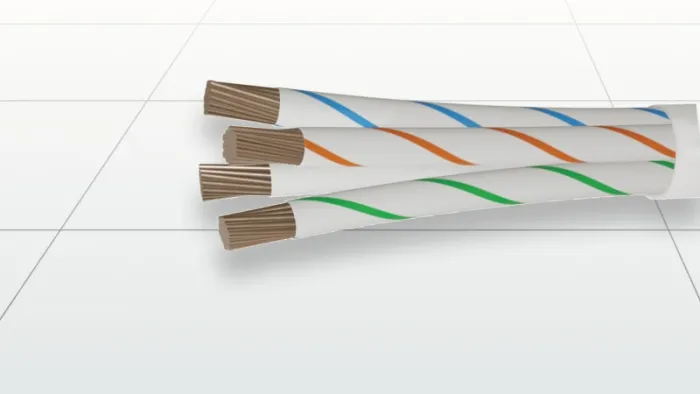

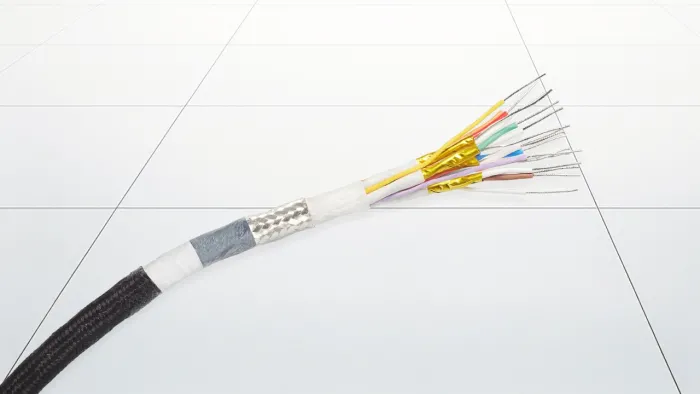

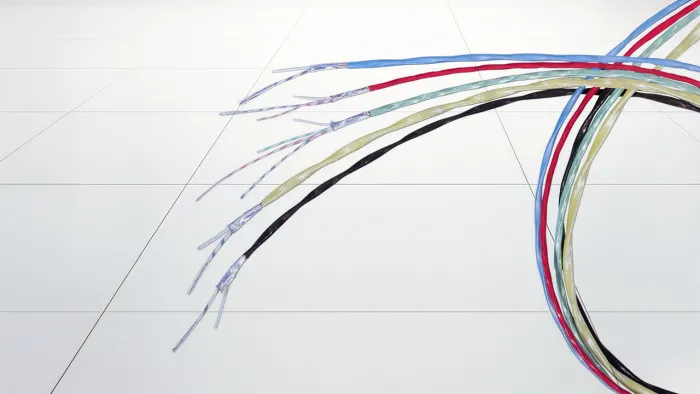

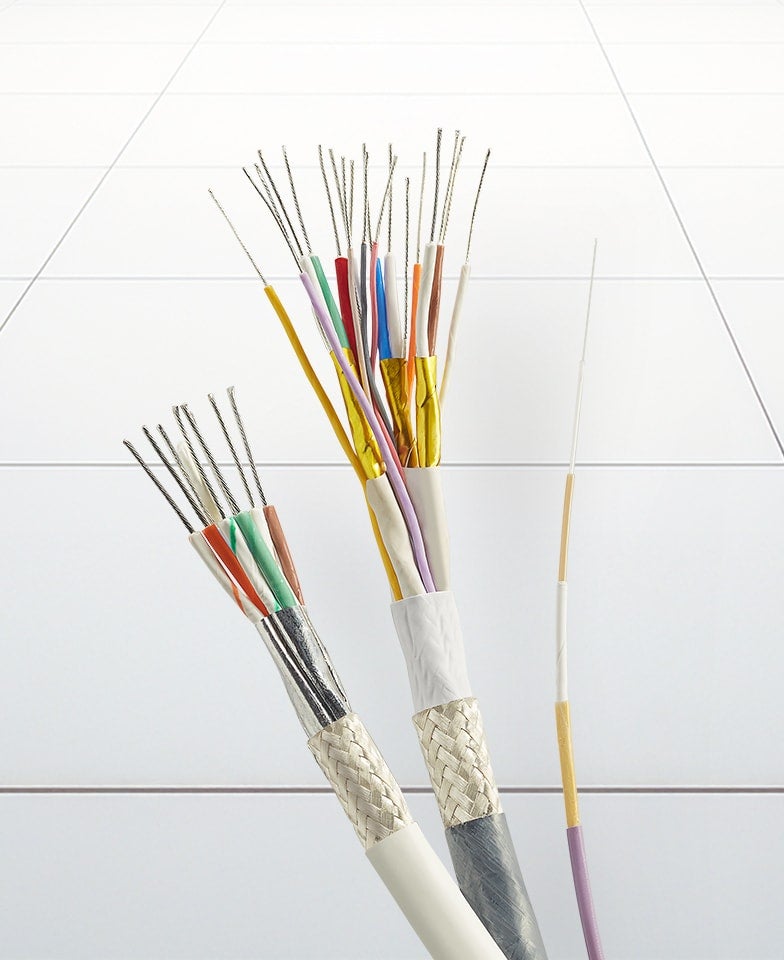

Cables are the lifeline of electronic systems, where a single failure can compromise an entire operation. They must withstand mechanical, electrical and environmental challenges and remain reliable across land, sea, air and space.

Gore’s durable, compact and flexible designs enhance performance in the harshest conditions, ensuring success in aviation, exploration, extraction and production.

Since 1958, we’ve pioneered fluorocarbon-insulated wires and cables. Today, we leverage our polymers and signal integrity expertise to deliver high-performance solutions for avionics, vetronics, semiconductors, oil well drilling tools and beyond.

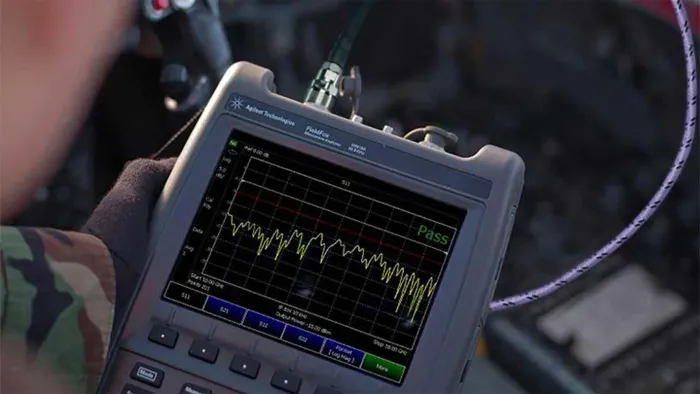

Courtesy of Keysight Technologies