GORE® Hook-Up Wires for Aerospace & Defense

Our standard wires distribute reliable power and signals, provide robust mechanical protection and offer size and weight savings.

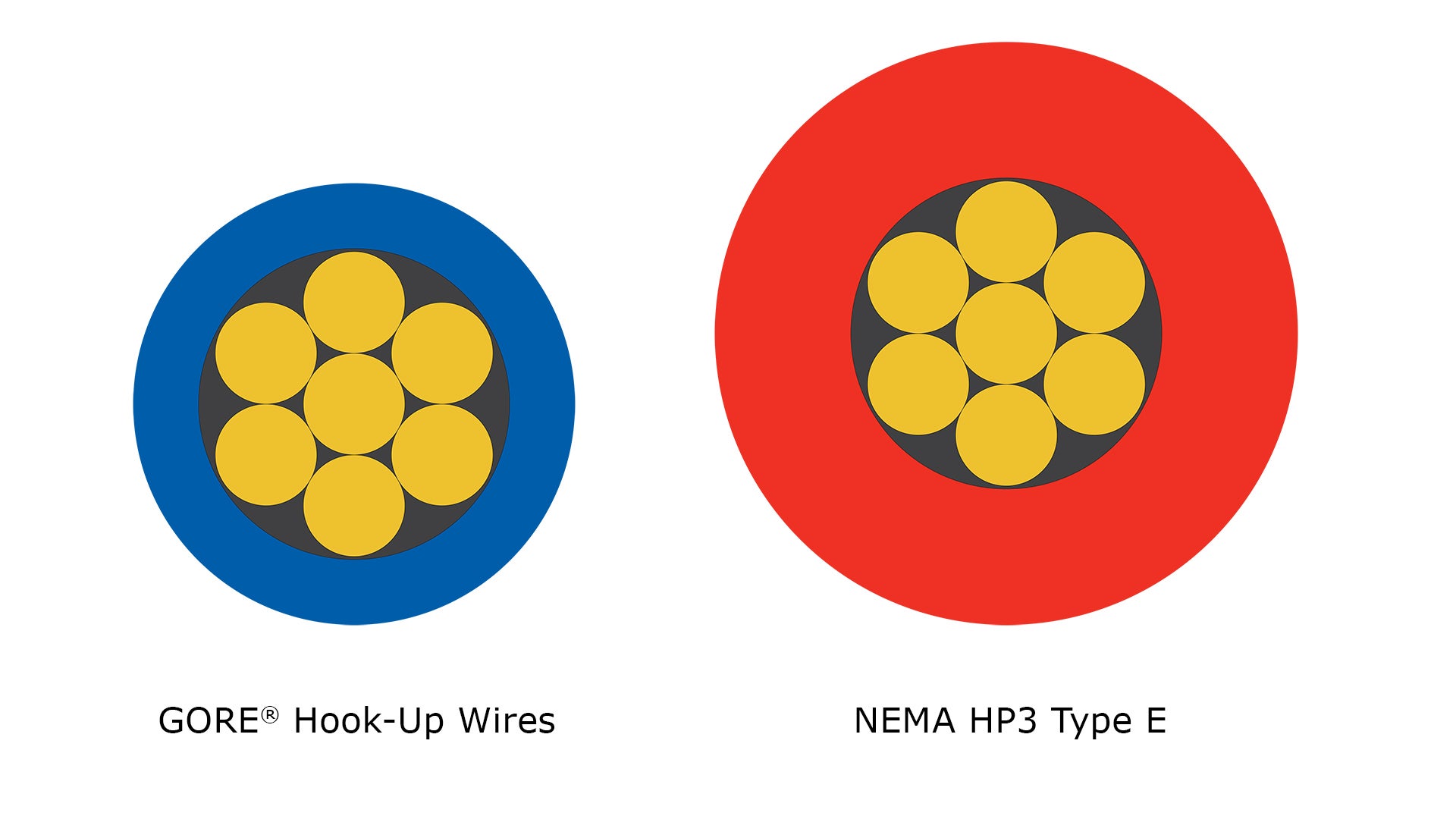

Smaller Wires Deliver Reliable Power & Signals

GORE® Hook-Up Wires provide robust protection in less space without short-circuiting. They withstand extreme temperature changes, among other challenging air, space and defense conditions. Our smaller, lighter wires deliver reliable power and signals for long-lasting performance, weight savings, less maintenance and reduced total cost.

Technical Information

These values demonstrate the electrical, mechanical and environmental performance of GORE Hook-Up Wires for aerospace and defense applications.

Elec./Mech./Environ. Property | Air & Defense | NewSpace |

|---|---|---|

Voltage Rating V | 100 to 1000 | 600 |

Jacket Material | PTFE | PFA |

Jacket Color | White (Laser Markable) | Yellow |

Wire Insulation Material | PTFE | Outer: PFA |

Conductor | Silver-Plated Coppera | Silver-Plated Copper or SPC Alloy, Stranded |

Conductor Color-Coding | Solid Stranded or Stripedb | Outer: Yellow |

Radiation Resistancec MRad | — | 10+ |

Temperature Range °C | SPC: -65 to +200 | -200 to +200 |

Downloads |

a Special conductors are available upon request.

b Available upon request for an additional cost.

c Test conducted using 3 MeV electron irradiation. Test method details available upon request.

GORE Hook-Up Wires have been thoroughly tested and qualified according to the following industry standards:

Air & Defense

- ASTM D3032/16-17: Test Methods for Hook-Up Wire Insulation

- MIL-STD-104: Limit for Electrical Insulation Color

- MIL-W-16878/20-22: Wire and Cable Specifications

NewSpace

- ESA ESCC 3901/018: Polyimide/Fluorothermoplast Insulated Wires and Cables, Low Frequency, 600V, -200 to +200 °C

- ESA ECSS-Q-ST-60-13C, Annex G Class 2: Space Product Assurance — Commercial Electrical, Electronic and Electromechanical (EEE) Components

- NASA EEE-INST-002 Level 2: Instructions for EEE Parts Selection, Screening, Qualification, and Derating

Featured Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.