GORE Mercury Control Systems

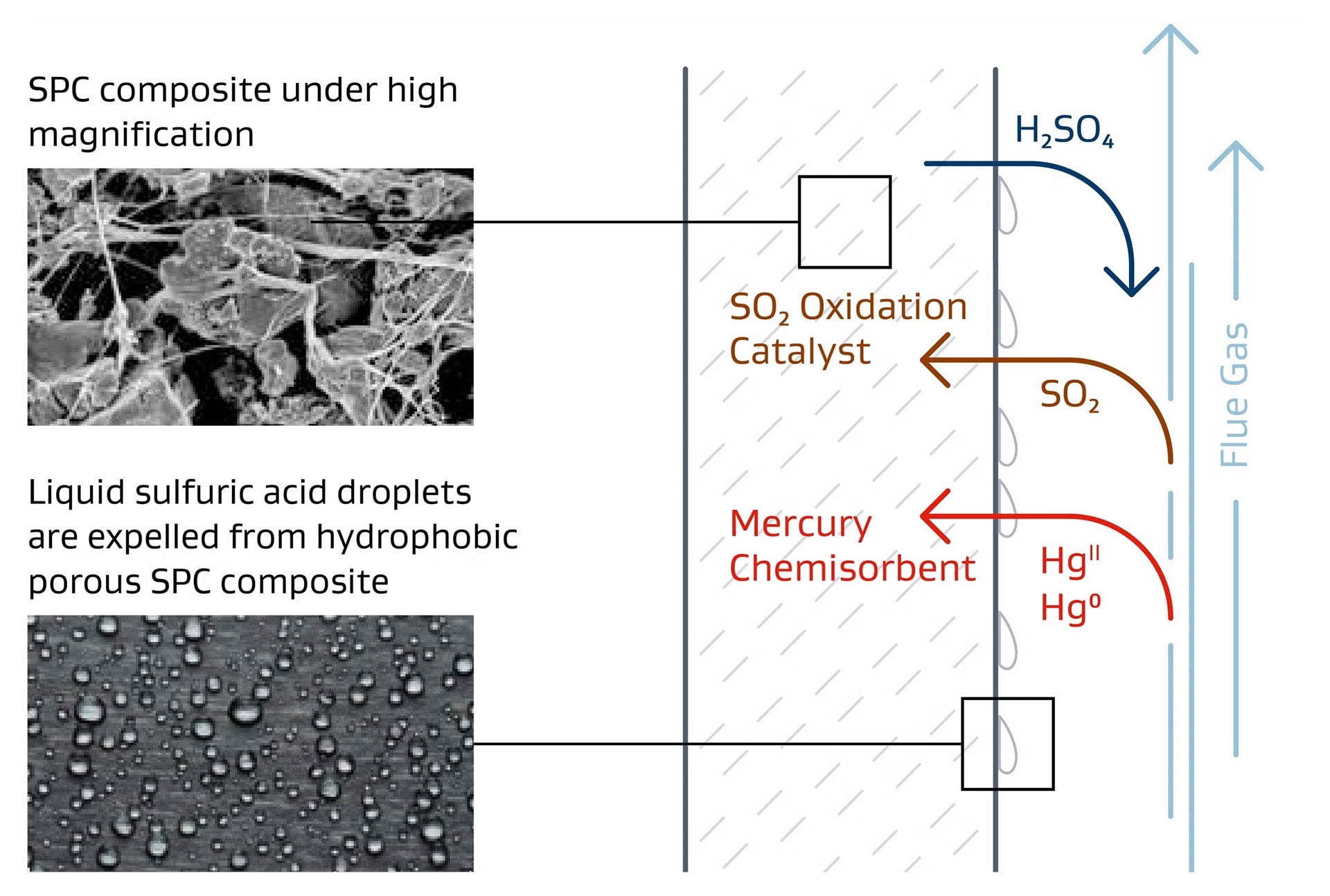

Our Mercury Control System provides both high efficiency and a high capacity for removing elemental and oxidized mercury from flue gas streams and reduces SO2 concentrations.

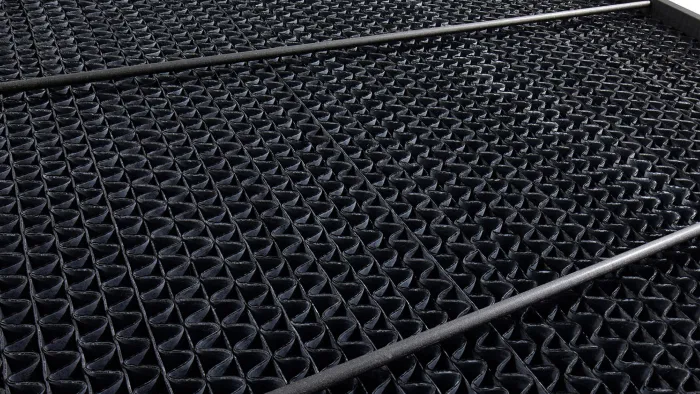

Unique, Scalable, Low-Cost Fixed Catalyst and Sorbent System

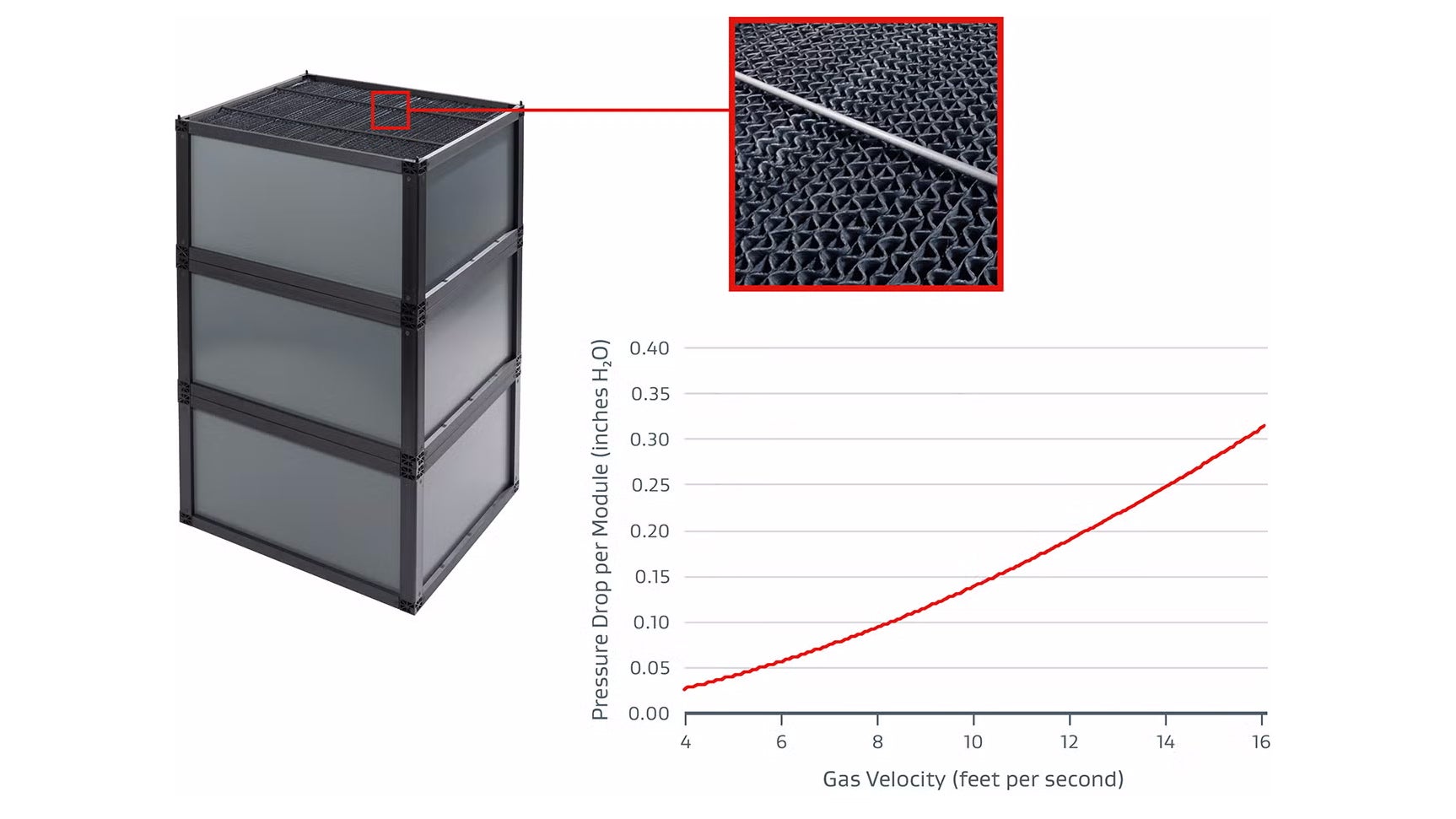

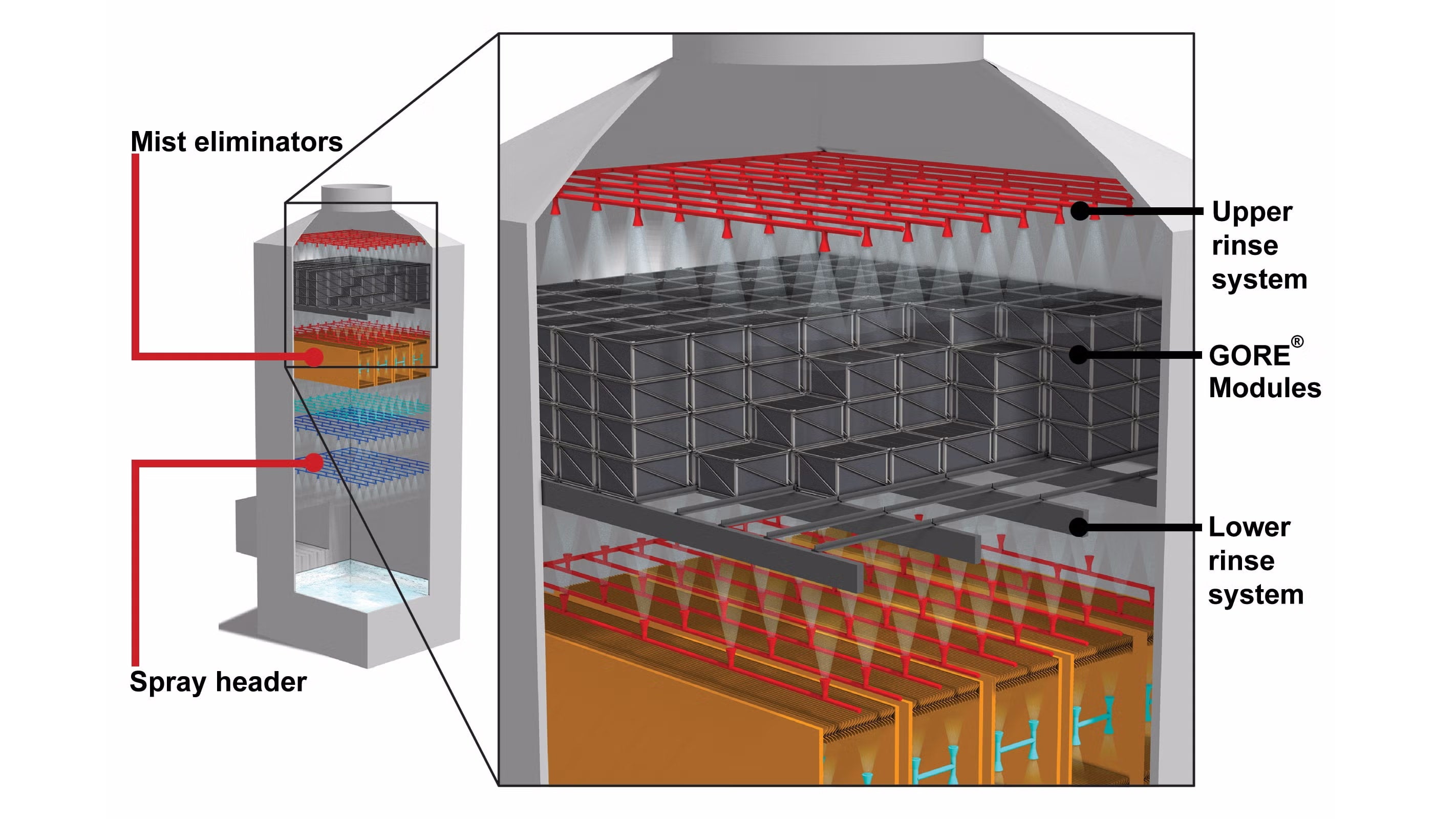

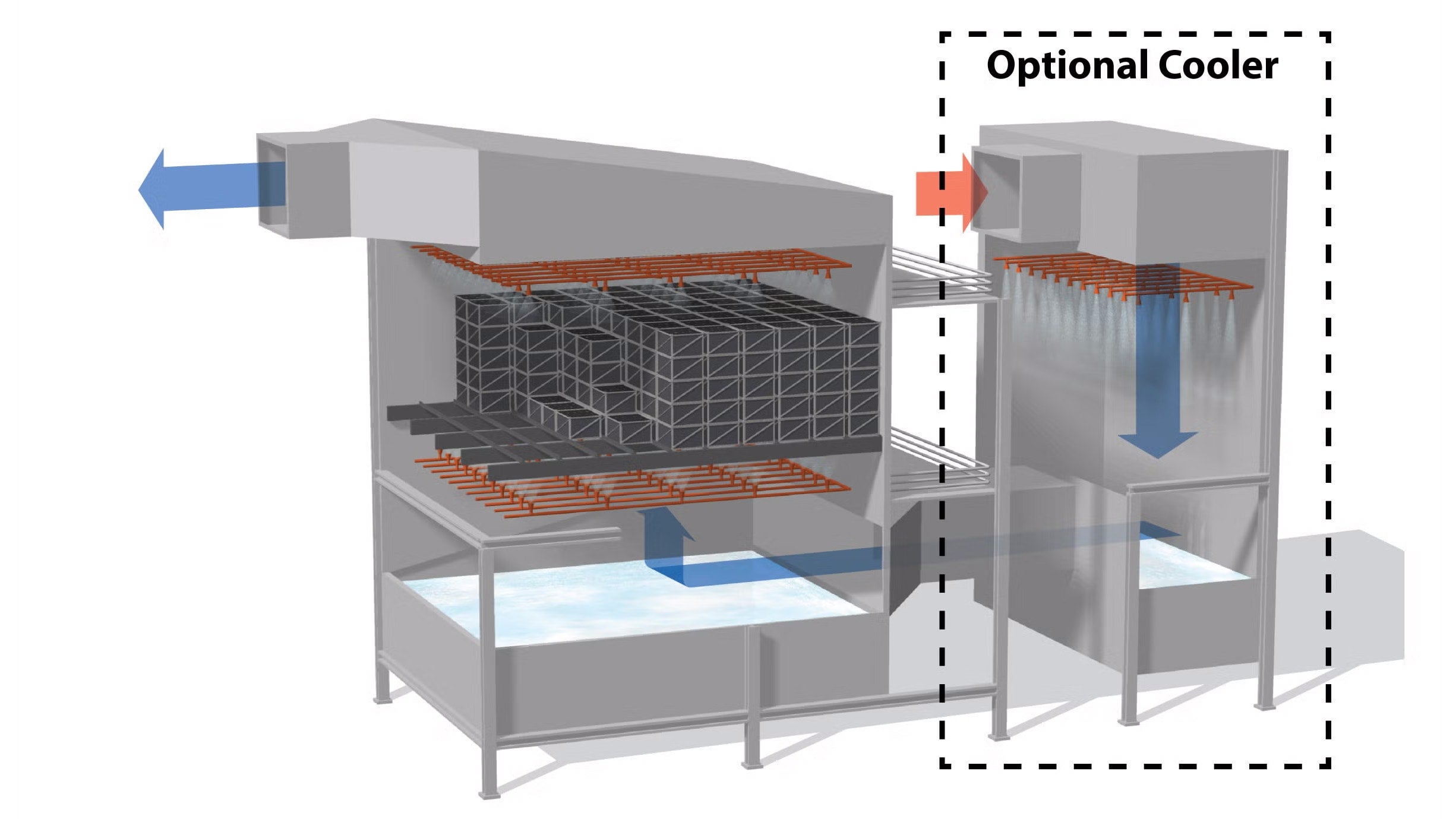

The GORE Mercury Control System (GMCS) is a unique fixed sorbent system for capturing elemental and oxidized gas phase mercury from industrial flue gas. The system is based on stackable modules that are installed downstream of a particulate collection system.

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 654 4229

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.