GORE Liners for Pressure Equalization in Sealed Packaging

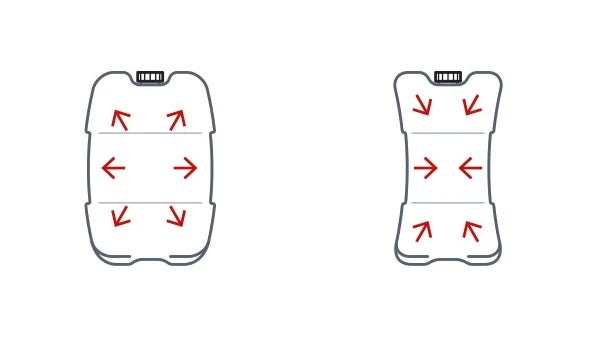

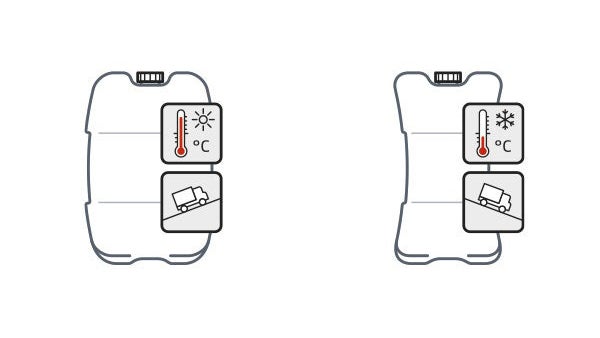

GORE Liners bring added versatility, economy and safety to a range of packaging applications, from household chemicals to fertilizers and pesticides.

Easy, Economical Integration. No Cap Modification

GORE Liners easily convert non-vented containers into vented containers without modifying the existing cap or closure. They are available in two series – Foam Liners and Pulp Induction Liners and provide unprecedented performance for the extreme challenges faced by fertilizers, pesticides, household chemicals and cleaners.

Technical Specifications

Order Number | 323G | 324G |

|---|---|---|

Typical Application | Bottles | |

Packaging Content |

| |

Product Performance Characteristics | ||

Typical Airflow at dP = 12 mbar | 0.7 l/h/cm2 | |

Water Entry Pressure (WEP) | > 1.4 bar | |

Traceability | On lot level | |

Membrane / Liner Construction | ePTFE / PE foam | |

Thickness | 1.1 mm | 1.9 mm |

Active Vent Area | Full Surface (Full diameter of liner) | |

Venting Method | Cap thread venting | |

Order Number | 383G | 384G |

|---|---|---|

Typical Application | Bottles | |

Packaging Content |

| |

Product Performance Characteristics | ||

Typical Airflow at dP = 12 mbar | 1.8 l/h/cm2 | |

Water Entry Pressure (WEP) | > 1.4 bar | |

Traceability | On lot level | |

Membrane / Liner Construction | ePTFE / PE foam | |

Thickness | 1.1 mm | 1.9 mm |

Active Vent Area | Full Surface (Full diameter of liner) | |

Venting Method | Cap thread venting | |

| Series Number | CM6B | CM6C | CM8C |

|---|---|---|---|

| Product Series | High Repellency Series | High Airflow Series | |

| Typical Airflow at dP = 12 mbara | 0.17 l/hb | 0.29 l/hb | 1.93 l/hb |

| Water Entry Pressure (WEP) | > 0.5 bar | > 0.3 bar | |

| Traceability | On lot level | ||

| Membrane / Liner Construction | ePTFE + PE + aluminum + PET + wax + pulp | ||

| Thickness | 1.0 mm | ||

| Active Vent Area | 0.6 mm | 2.0 mm | |

| Venting Method | Cap thread venting | ||

a This value is based on an optimum closure bottle design in combination with a typical closure torque.

b This value is based on a roll good slit width of 52.3 mm intended for disc diameters up to 46.3 mm.

c This value is based on a roll good slit width of 69.9 mm intended for disc diameters up to 63.9 mm.

Related Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 866 348 4673

Have questions or unique requirements?

Our experts are here to guide you.