GORE® Microwave RF Assemblies, General Purpose

Our small, flexible assemblies deliver stable electrical performance in many application and testing environments across industries for fewer replacements and less total costs.

Maximum Flexibility, Excellent Electrical Performance

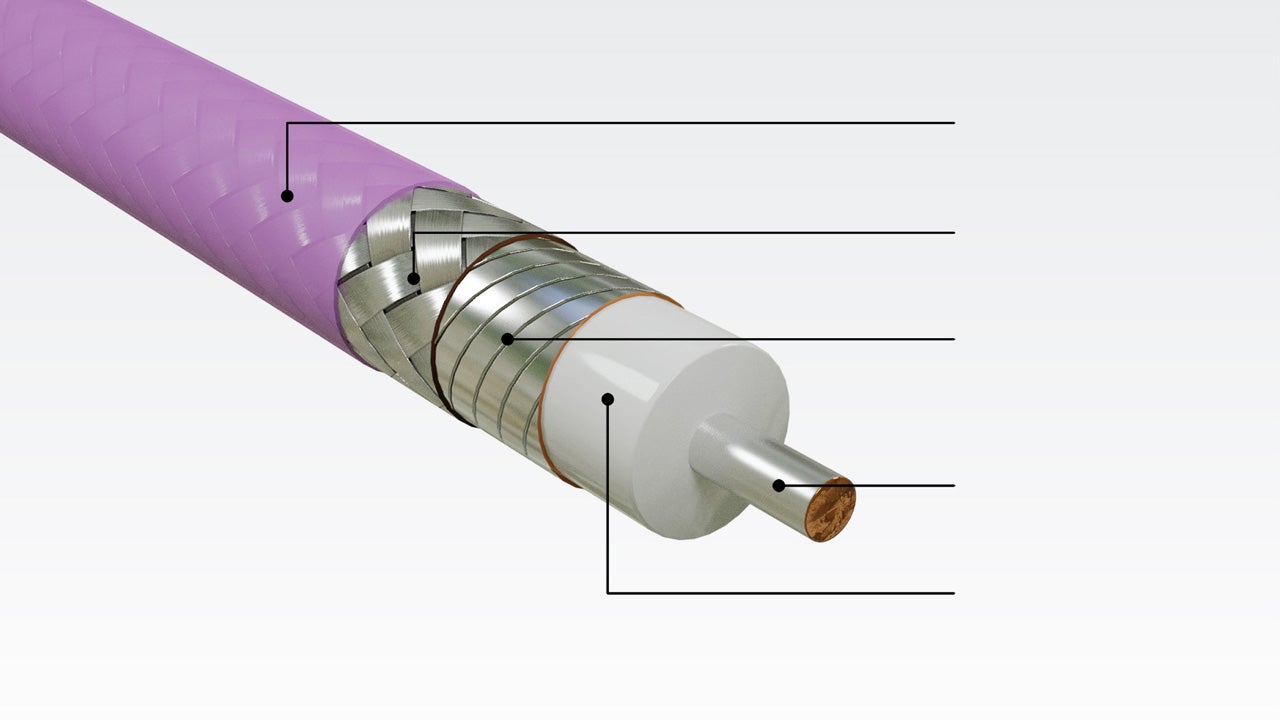

GORE® Microwave RF Cable Assemblies offer small, light, flexible general purpose options up to extremely high frequencies (EHF). Our low-loss coaxial cables are proven to maintain excellent electrical performance and shielding effectiveness with phase and amplitude stability over time. They’re easier to handle and hold up to tight routing compared to RF or semi-rigid cables.

Technical Information

GORE Microwave RF Assemblies for general purpose are identified by a 13-character part number that designates the cable type, connector types, assembly length and T/V identifier for thermal vacuum chamber use.

Positions 1–2: Two-letter code representing each cable type (e.g., 4L, 89, 2Z, 55, etc.).

Positions 3–5: Connector A that attaches to the left side of the cable assembly.

Positions 6–8: Connector B that attaches to the right side of the cable assembly

Positions 9–12: The assembly length is expressed in inches to the nearest tenth, including zeroes to fill positions if the length is less than three digits. For example, the length of a 24-in assembly is specified as 0240.

Position 13: Identifier T/V included only for an assembly prepared for thermal vacuum chamber use.

Example part numbers of our cable types include the following:

4LS01S010120

4LS01S010120-TV

890CQ0CQ0600

890CQ0CQ0600-T/V

G5D02D020240

G5D02D020240-TV

2Z0AK0AK0360

2Z0AK0AK0360-TV

G3R01R010120

G3R01R010120-TV

8WQ01Q010480

8WQ01Q010480-TV

Connector Options

For all of our cable types, we offer a variety of standard connector options specifically designed to optimize the performance of each assembly, like SMA, SMP, TNCA, 2.92 mm and more.

Featured Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 626 7708

Have questions or unique requirements?

Our experts are here to guide you.