GORE® RASTEX® Sewing Thread for Filtration Applications

Our high temperature industrial thread is engineered for the demands of filtration applications, and withstands exposure to chemicals, high temperatures, abrasives, and moist environments.

High Performance, Low Shrinkage at Elevated Temperatures

GORE® RASTEX® Sewing Thread combines excellent chemical resistance, superior strength, greater flexibility, high abrasion resistance and dimensional stability. It’s engineered for outstanding sewability and will not fibrillate.

Technical Information

Why Do Sewn Filter Bags and Cartridges Fail?

Filter bags, cartridges, and other sewn filter media are exposed to extreme temperatures chemicals, abrasives, and, occasionally, moist environments, for extended periods. These conditions degrade the filter media and thread, and the thread often gives out first. In some cases the thread is not appropriate for the application, or it simply wears out from chemical, temperature, or abrasive attack before the filter media.

Why Is the Breaking Strength of PTFE Filtration Sewing Threads So Crucial at High Temperatures?

PTFE Filtration Sewing Threads are almost always used in situations where aggressive chemicals or gases at very high temperatures of 200°C - 260°C act on the filter media and their seams. In this temperature range, high-quality GORE RASTEX Fibers Sewing Threads made from expanded PTFE are superior to other PTFE products on the market, in some cases considerably so, with their long-lasting, high endurance strength. This is vitally important to the lifetime of the filter, significantly reducing the number of changeover cycles and achieving superior reliability throughout the entire usage period.

Why Are the Shrink Characteristics of PTFE Filtration Sewing Threads So Important at High Temperatures?

In practice PTFE Filtration Sewing Threads are exposed to temperatures of 230°C - 260°C. This heat results in “hot air shrinkage” of the threads and therefore the filter seams. In GORE RASTEX Fibers Sewing Threads made from expanded PTFE, the shrinkage is significantly less than 3%, making it a very high-quality product compared with other products on the market. High shrinkage inevitably results in shortened, non-dimensionally stable seams that may impair the function and performance of the filter.

Product Range

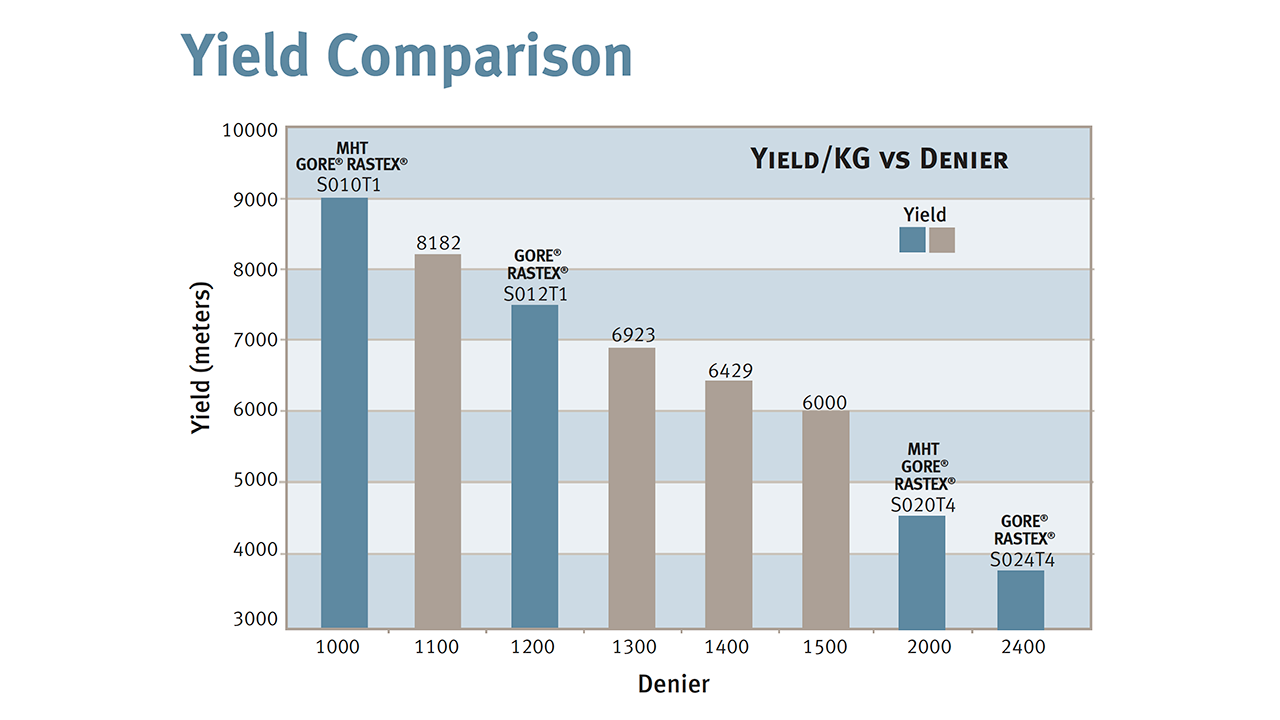

ORIGINAL GORE® RASTEX® SEWING THREAD

| PART NUMBER | DENIER/DTEX | NOMINAL BREAK STRENGTH LBS/CN | YIELD per KG Meters | Color |

|---|---|---|---|---|

S012T1 | 1200/1333 | 12/5338 | 7500 | Natural White |

S024T4 | 2400/2666 | 24/10676 | 3750 | Natural White |

MHT GORE® RASTEX® SEWING THREAD

| PART NUMBER | DENIER/DTEX | NOMINAL BREAK STRENGTH LBS/CN | YIELD per KG Meters | Color |

|---|---|---|---|---|

S010T1 | 1000/1111 | 12/5338 | 9000 | Natural White |

S020T4 | 2000/2222 | 24/10676 | 4500 | Natural White |

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 276 8451

Have questions or unique requirements?

Our experts are here to guide you.