GORE® PEM for Water Electrolysis

Optimizing performance and lowering costs for Proton Exchange Membrane electrolyzers — without compromising output.

Achieving New Levels of Hydrogen Electrolysis Efficiency and Scalability

Green hydrogen production must scale up significantly to achieve our net-zero ambitions. However, the water electrolysis (WE) market has a challenging operational landscape.

Engineers must solve the “system dilemma” of optimizing performance, safety and durability — where strengthening one vector could mean compromising on the others.

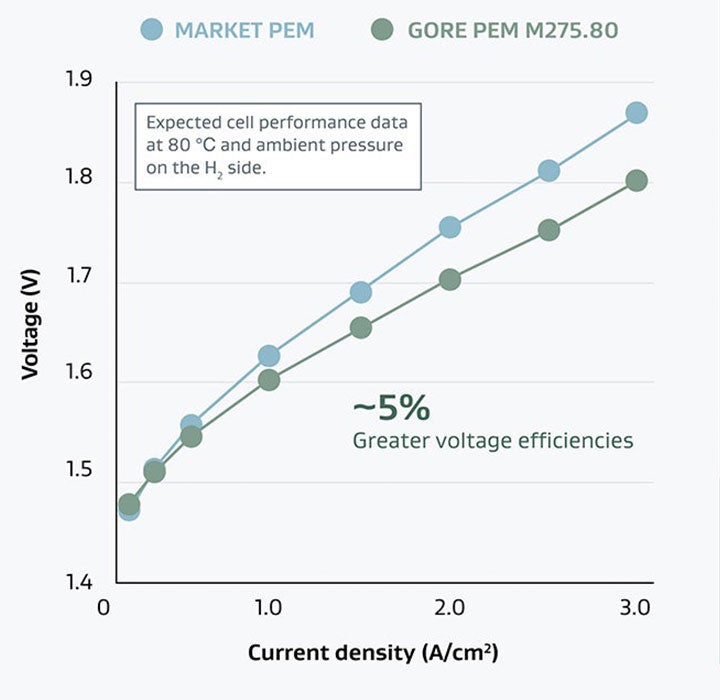

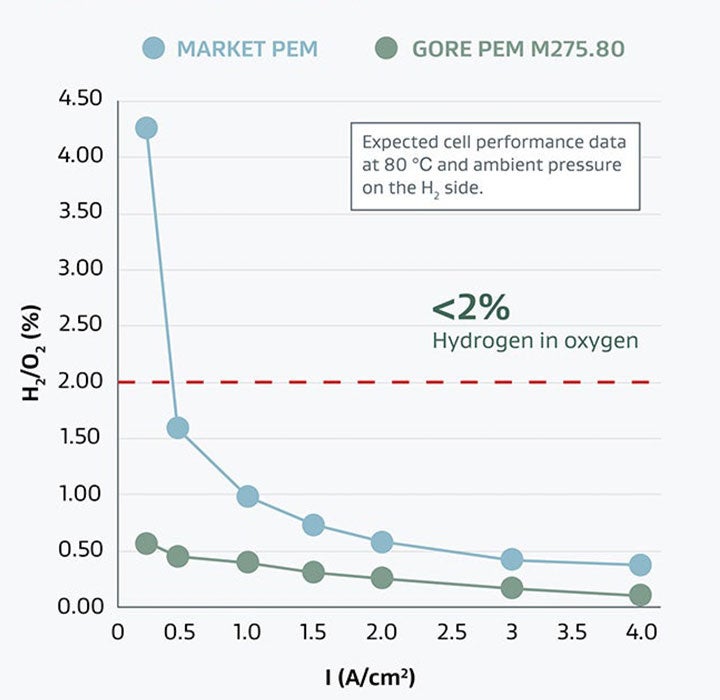

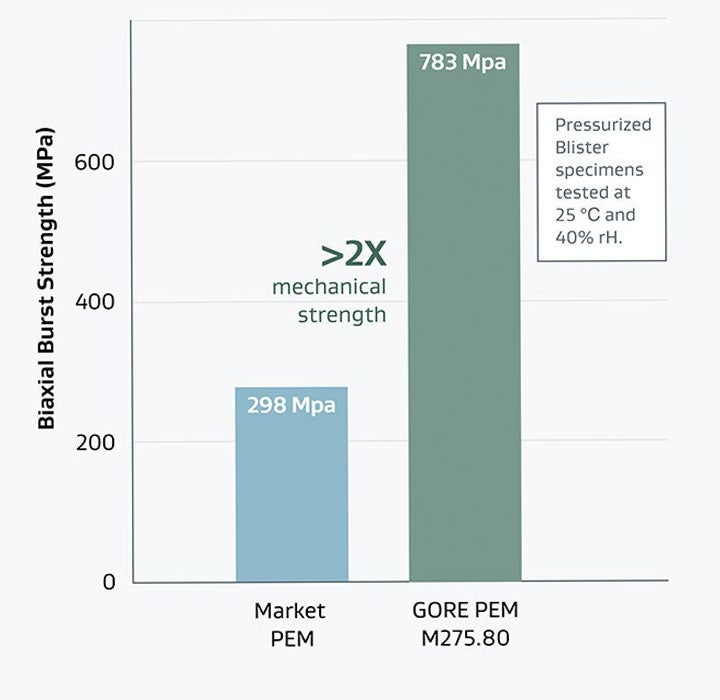

GORE® PEM for Water Electrolysis M275.80 breaks through performance barriers by optimizing all three vectors at the same time.

Our advanced membrane achieves new levels of hydrogen electrolysis efficiency and scalability, lowering the levelized cost of hydrogen (LCOH).

For over three decades, we've led the market in producing proton exchange membranes (PEM) for fuel cells.

Today, our state-of-the art production facilities and enterprise capabilities are available immediately to support multi-gigawatt water electrolysis systems.

Powering the Clean Energy Transition With Scalable PEM Technology: Gore is Designed to Deliver

PEM vs Other Electrolysis Technologies

| Positive Attributes | Negative Attributes | Technology Readiness Level (TRL) |

|---|---|---|

|

| TRL 8-9 (proven performance in many industry applications) |

| Positive Attributes | Negative Attributes | Technology Readiness Level (TRL) |

|---|---|---|

|

| TRL 9 (most mature, widespread + scaled) |

| Positive Attributes | Negative Attributes | Technology Readiness Level (TRL) |

|---|---|---|

|

| TRL 7-8 (advancing TRL and in prototype applications in the market) |

| Positive Attributes | Negative Attributes | Technology Readiness Level (TRL) |

|---|---|---|

|

| TRL 5-7 (early-stage project development) |

GORE PEM M275.80 Technical Data

| Physical Characteristics | |

|---|---|

| Thickness1 [µm] | 80 |

| Tensile strength1 in Machine Direction [MPa] | 55 |

| Tensile strength1 in Transverse Direction [MPa] | 55 |

| Proton resistance2 [mOhcm2] | 57 |

| H2 permeance3 [mA/cm2/MPa] | 7 |

| Roll Properties | |

|---|---|

| Standard roll widths [mm] | 320, 400, 580 |

| Length [m] | 100 |

| Orientation | Product in roll form is shipped with the membrane anode side facing outwards |

1 Measurements taken with membrane conditioned to 23 °C, 50% relative humidity (RH).

2 Proton resistance measurements taken by high frequency resistance method. Membrane impedance taken at zero imaginary impedance.

3 Hydrogen permeance measurements taken by cyclic voltammetry (CV).

| Quality Assurance | |

|---|---|

| Product visual inspection for defects | 100% automated |

| Clean room standard ISO 14644-1 | Class 7 (Class 10,000) |

Featured Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 542 2624

Have questions or unique requirements?

Our experts are here to guide you.