GORE Plug-In Packaging Vents for Chemical Ventilation

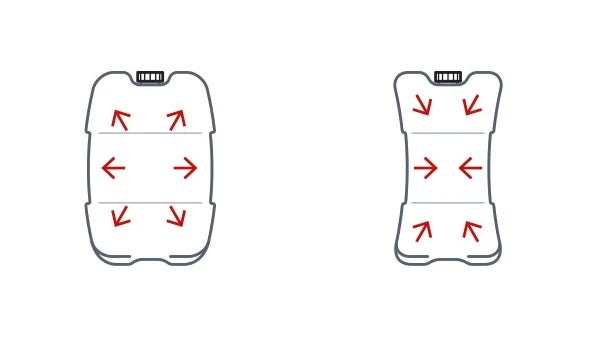

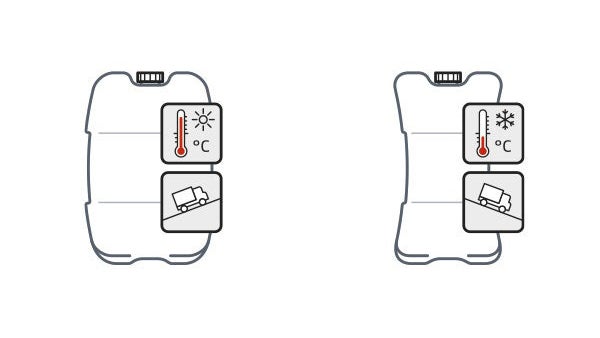

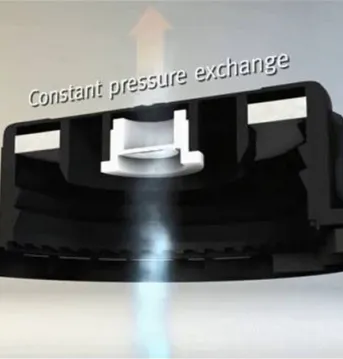

GORE Plug-In Vents safely equalize pressure differences that could cause containers of liquid chemicals to deform, leak or burst. They reliably perform even with the most challenging formulations.

Minimize the Risks in Chemical Solution Packaging, Transport and Handling

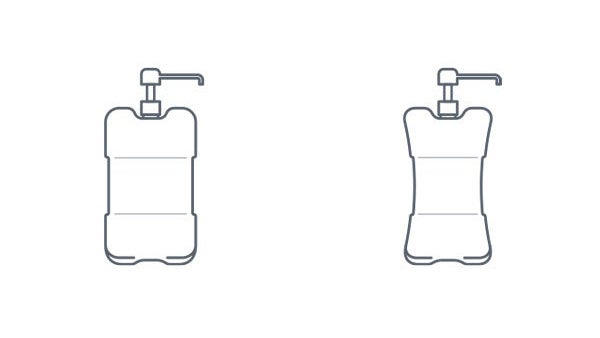

GORE Packaging Vents meet stringent ADR and DOT standards. From vented caps for bottles to plastic bottle cap seal liners, they are designed to reliably protect the integrity of containers that bear the most challenging contents, including liquid chemicals, highly concentrated formulations and highly active ingredients.

GORE® Packaging Vents Competence

See how our packaging vents are custom constructed for their applications.

Technical Information

Gore monitors and strives to comply with all regulations applicable to our products.

We have worked with our suppliers to eliminate PFOA from our supply chain. Our products meet EU REACH regulations EU 1907/2006 and EU 2019/2021.

Featured Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 866 348 4673

Have questions or unique requirements?

Our experts are here to guide you.