Ambient Air Filters for Outdoor Cabinets

GORE® Cooling Filters provide years of maintenance-free life to sensitive electronics through ambient air cooling, without the risk of corrosion from airborne contaminants.

Highly Reliable Cooling Technology

GORE Cooling Filters (GCF) enable you to lower your system costs by taking full advantage of the natural thermal efficiencies of ambient air. Our filters provide years-long protection against harmful contaminants and corrosion and require no regular maintenance.

Technical Specifications

Construction Materials

| Frame | ABS Black |

|---|---|

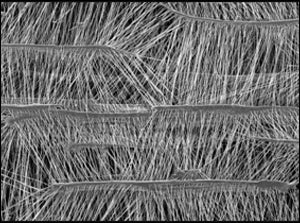

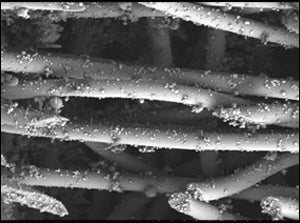

| Membrane | Hydrophobic ePTFE |

| Pleated Filter Media | Fully Synthetic Composite |

| Potting | Polyurethane |

| Gasket | Polyurethane Foam/Thermoplastic Elastomer |

Product Performance

| Operating Temperature | –40 to +65 °C |

|---|---|

| Humidity Range | 0 to 100% RH |

| Filtration Efficiency | > 99.5% (@ 0.1 μm, 1 cm/sec) |

| Filtration Class | EN1822 – E12 |

| Flammability | UL 900 |

| Typical Filter Lifetime | Up to 5 years (based on application)2 |

2 Installation location impacts PM10 air pollution assumptions used in lifetime projections

The Filter Performance table shows relative performance at standard parameters. Specific calculations are required for individual installations and may differ from standard parameters.

Gore application engineers can help you determine your heat dissipation needs and calculate the recommended filter performance and size for your specific application.

Typical Performance Characteristics per Filter Size

| Part Number | Filter Attributes | Filter Performance | |||||

|---|---|---|---|---|---|---|---|

| Height (mm) | Width (mm) | Depth (mm) | Weight (kg) | Maximum Air Flow (m3/hr) | Equivalent Heat Dissipation Capacity (W) 1 | New Filter Pressure Drop (ΔP) vs. Airflow (Q) Curves | |

| CF541163 | 692 | 500 | 48 | 2.7 | 500 | 1613 | ΔP (Pa) = 0.11 x Q (m³/h) |

| CF541211 | 200 | 345 | 90 | 1.2 | 162.5 | 524 | ΔP (Pa) = 0.34 x Q (m³/h) |

| CF541237 | 605 | 454.5 | 57.2 | 2.2 | 450 | 1452 | ΔP (Pa) = 0.12 x Q (m³/h) |

| CF541238 | 455 | 305 | 57.2 | 1.2 | 200 | 645 | ΔP (Pa) = 0.28 x Q (m³/h) |

| CF541239 | 305 | 230 | 57.2 | 0.7 | 100 | 323 | ΔP (Pa) = 0.56 x Q (m³/h) |

| CF541242 | 605 | 455 | 80 | 3.3 | 625 | 2016 | ΔP (Pa) = 0.09 x Q (m³/h) |

| CF541252 | 305 | 455 | 57.2 | 1.2 | 212.5 | 685 | ΔP (Pa) = 0.26 x Q (m³/h) |

| CF541257 | 494 | 440 | 57.4 | 1.9 | 337.5 | 1089 | ΔP (Pa) = 0.17 x Q (m³/h) |

| CF541258 | 850 | 440 | 57.2 | 3.0 | 625 | 2016 | ΔP (Pa) = 0.09 x Q (m³/h) |

| CF551278 | 205 | 440 | 80 | 1.2 | 187.5 | 605 | ΔP (Pa) = 0.30 x Q (m³/h) |

| CF551279 | 440 | 440 | 80 | 2.4 | 450 | 1492 | ΔP (Pa) = 0.12 x Q (m³/h) |

- Fan Selection: Choosing the right fan with the appropriate level of control is crucial to extend filter life and maintain stable temperatures. GORE Cooling Filters start with a resistance of 50 Pascals, increasing over time.

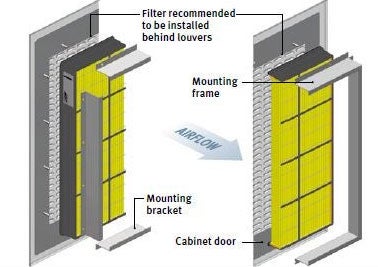

- Filter Sealing: A gasket in the frame ensures a good seal between the enclosure and the filter.

- Design and Mounting: Mounting is typically done with brackets or frames to ensure pleats stay vertical. Follow the airflow direction on the label and ensure consistent gasket compression around the perimeter. At least 10mm clearance should be given on each side to prevent distortion.

- Contact a Gore specialist with questions about fan selection, design and filter installation.

| Ingress Protection Testing | Wind Driving Rain Testing | Flammability Testing | |

|---|---|---|---|

| Filter protection against ingress of particulates and water | Resistance to open flame | ||

| METHOD: IEC 60529 | RATING: IP653 | METHOD: GR 487-CORE Comply with the 31 m/sec [70 mph] 3 | METHOD: UL 900 |

| Salt Fog Testing | Filter Attributes |

|---|---|

| Filter resistance to salty environments | |

METHODS:

| METHOD:

|

3 Enclosure test; filter supports this performance when installed in sealed enclosure with louver protecting filter

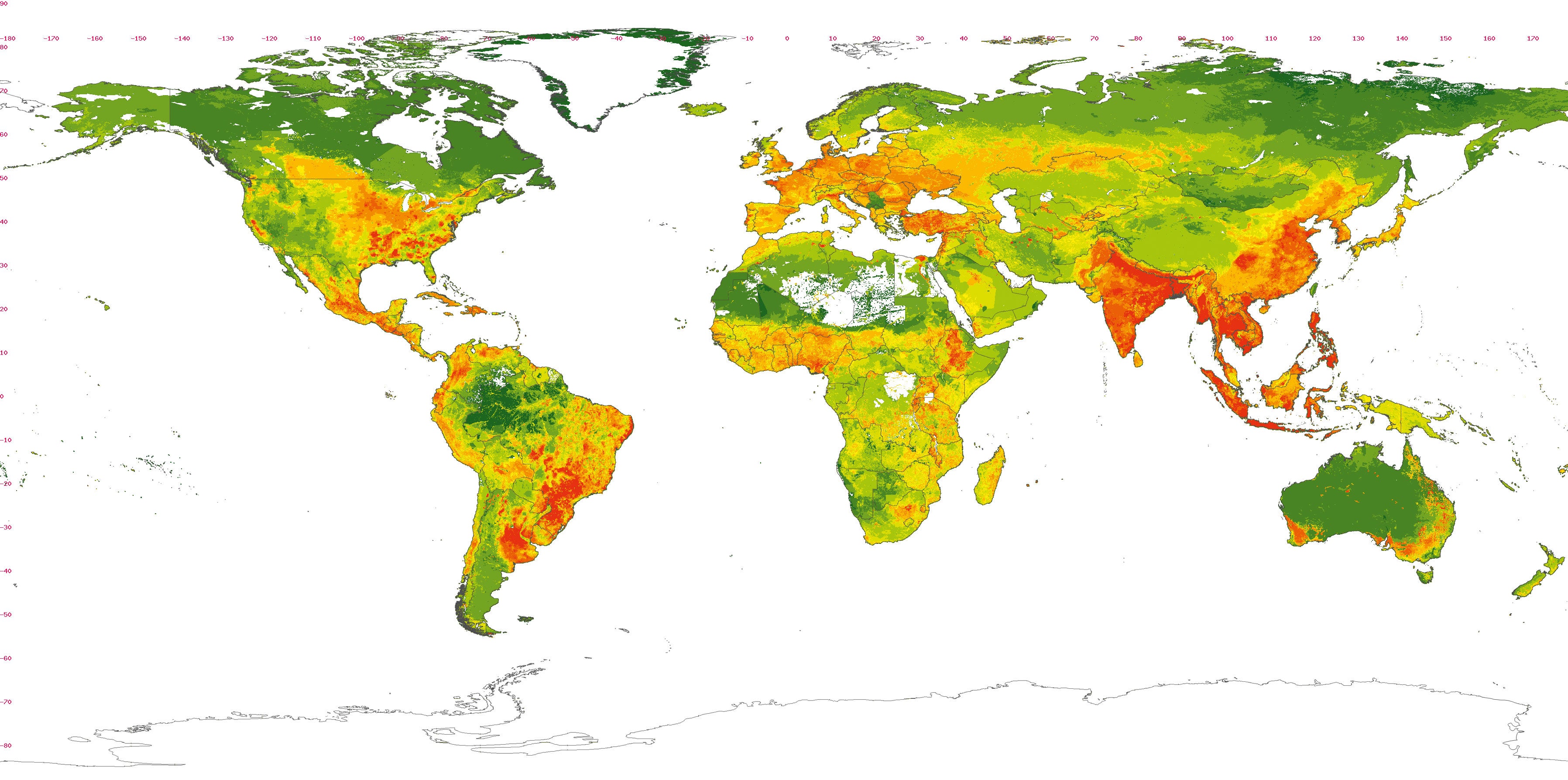

Environmental challenges: PM10 particles in the air

Global Field Testing / Theoretical Lifetime Modelling

The environmental conditions in the deployment locations of outdoor electronic enclosures are highly variable. Even highly sophisticated computer simulation or laboratory testing cannot adequately predict the long-term performance of filters used for ambient air filtration in every situation. In our global field test program, cabinets using GORE Cooling Filters were deployed to evaluate lifetime of filters in different air pollution environments with particles of different natures and origins. With this research, theoretical models were validated with empirical data collected from the field test unit in high air pollution areas.

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 231 4364

Have questions or unique requirements?

Our experts are here to guide you.