GORE® Turbine Filters for Air Inlet Filtration

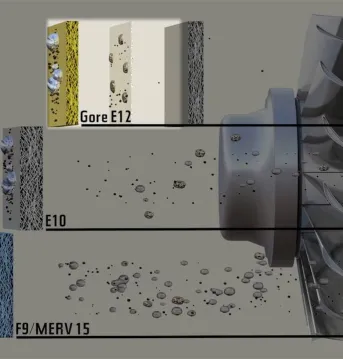

Upgrading to GORE® Turbine Filters with E12 hydrophobic HEPA technology has provided enormous value to rotating equipment users.

Reduce Maintenance with Durable Industrial Air Filters

E12 high-efficiency particulate air (HEPA) filters from Gore are engineered to keep your turbines up and running for the long haul. This durable watertight filtration technology is proven to maintain clean engine performance, minimize downtime and lower maintenance costs over the filter’s lifetime.

How High Efficiency Air Filters Can Increase Gas Turbine Availability

Listen to Gore’s Dr. Holger Stolpmann explain how high efficiency air filters can increase gas turbine availability.

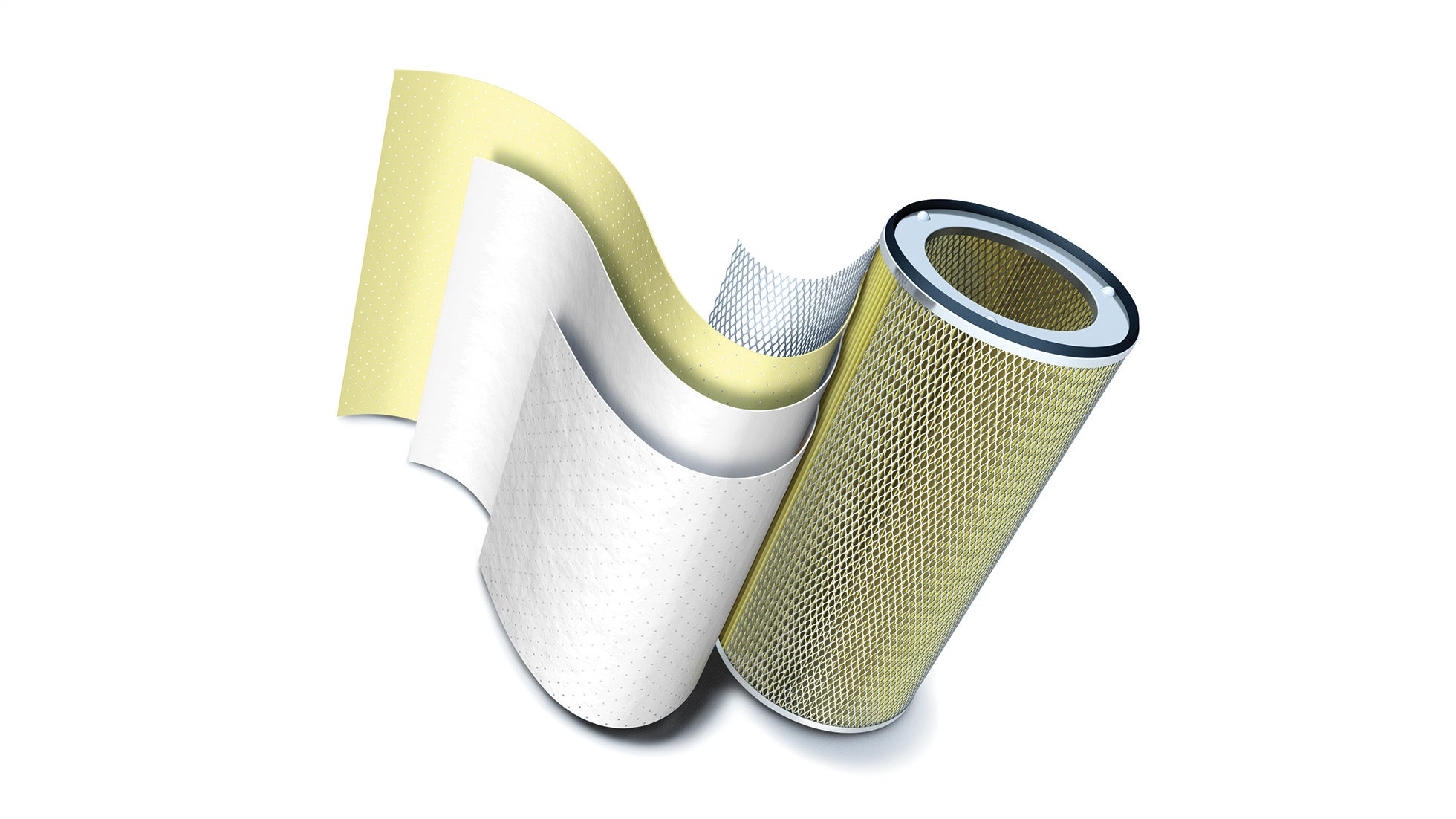

Advanced Media Developed Specifically for Ambient Air Filtration

Learn how GORE Turbine Filters keep fine particles, dirty water and salt out of gas turbines.

Technical Specifications

| Conical & Cylindrical Filter Pair | Cylindrical Filters | V-Panel Filters | Pulse Panel Filters | Z-Panel Filters | Composite Filters | Flange Top Cartridge Filters | |

|---|---|---|---|---|---|---|---|

| Operational Mode | Pulse cleanable & static | Pulse cleanable & static (for arctic or desert environments) | Static | Pulse cleanable & static | Static | Static | Pulse cleanable & static (for arctic or desert environments) |

| Filter Media | Fully synthethic composite with ePTFE membrane | Fully synthethic composite with ePTFE membrane | Fully synthethic composite with ePTFE membrane | Fully synthethic composite with ePTFE membrane | Fully synthethic composite with ePTFE membrane | Fully synthethic composite with ePTFE membrane | Fully synthethic composite with ePTFE membrane |

| Structural Components | Galvanized Steel | Galvanized Steel | Polymer | Galvanized Steel | Polymer | Galvanized Steel | Galvanized Steel |

| Potting | Polyurethane | Polyurethane | Polyurethane | Polyurethane | Polyurethane | Polyurethane | Polyurethane |

| Gasket | EPDM Rubber | EPDM Rubber | PU Foam | PU Foam | PU Foam | EPDM Rubber | EPDM Rubber |

| Efficiency | E12 according to EN 1822 Min 99.5% @MPPS | E12 according to EN 1822 Min 99.5% @MPPS | E12 according to EN 1822 Min 99.5% @MPPS | E12 according to EN 1822 Min 99.5% @MPPS | E12 according to EN 1822 Min 99.5% @MPPS | E12 according to EN 1822 Min 99.5% @MPPS | E12 according to EN 1822 Min 99.5% @MPPS |

| Wet Burst Pressure | >7500 Pa (30" wg) | >7500 Pa (30" wg) | >6250 Pa (25" wg) | N/A | >5000 Pa (20" wg) | >7500 Pa (30" wg) | >7500 Pa (30" wg) |

| Initial Pressure Drop | 180 Pa @ 2500 m3/h (.72" wg @ 1472 cfm) | TCU017: 220 Pa @ 1250 m3/h (0.9 in wg @736 cfm) TCU018: 195 Pa @ 1050 m3/h (0.8 in wg @ 618 cfm) TCU019: 225 Pa @ 1300 m3/h (0.9 in wg @ 765 cfm) TCU037: 285 Pa @ 1650 m3/h (1.2 in wg @ 971 cfm) | V12: 235 Pa @ 3400 m3/h (.94 " wg @ 2000 cfm) V15: 180 Pa @ 3400 m3/h (.71" wg @2000 cfm) V18: 155 Pa @ 3400 m3/h (.62" wg @ 2000 cfm) | 230 Pa @ 4250 m3/h (.92" wg @ 2500 cfm) | 135 Pa @ 3400 m3/h (.53" wg @ 2000 cfm) 180 Pa @ 4250 m3/h (.71" wg @ 2500 cfm) | TCU011: 161 Pa @ 2550 m3/h (0.65 in wg @ 1500 cfm) TCP022 Insert: 225 Pa @ 2550 m3/h (0.90 in wg @ 1500 cfm) | TCU020: 140 Pa @ 1000 m3/h (0.6 in wg @ 588 cfm) TCU022: 190 Pa @ 1000 m3/h (0.8 in wg @ 588 cfm) TCU026: 140 Pa @ 1000 m3/h (0.6 in wg @ 588 cfm) TCU034: 140 Pa @ 1000 m3/h (0.6 in wg @ 588 cfm) |

Featured Content

Related Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 231 4364

Have questions or unique requirements?

Our experts are here to guide you.