GORE® Fibre Channel Cables for Aerospace & Defense

Our smaller, lighter, durable cables maximize the performance of quadrax designs for more protection and weight savings than alternatives. Proven on many airborne platforms, these high-speed interconnects maintain reliable signals, enhance noise immunity and improve EMI protection.

Reliable Signal Integrity at High Data Rates

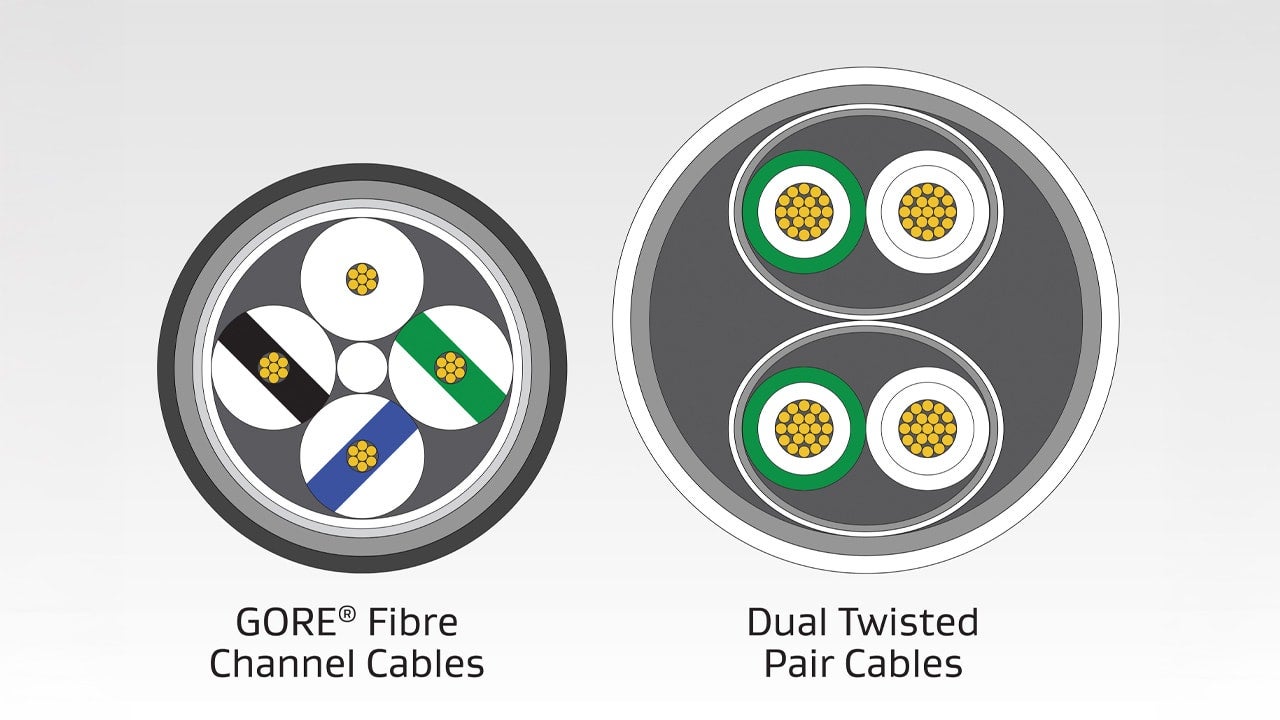

GORE® Fibre Channel Cables are a reliable, low-dielectric constant solution that boosts durability against typical aircraft environments like extreme temperatures, aggressive chemicals and more. Featuring a balanced quadrax design with field-cancellation properties, they transmit two different signals within the same shield without interference. They’re proven to maintain consistent signal integrity at high data rates up to 1.625 GHz.

Technical Information

These values demonstrate the electrical, mechanical and environmental performance of GORE Fibre Channel Cables for defense and civil aircraft.

| Elec./Mech./Environ. Property | Value |

|---|---|

| Signal Transmission Speed GHz | Up to 1.625 |

| Standard Impedance Ohms | 150 ± 15 |

| Typical Operating Voltage Rating V | < 15 |

| Nominal Velocity of Propagation % | 87 |

| Nominal Time Delay ns/m (ns/ft.) | 4.0 (1.22) |

| Capacitance pF/m (pF/ft.) | 28.2 (8.6) |

| Typical Skew Within Pair ps/m (ps/ft.) | 3.0 (0.9) |

| Dielectric Withstanding Voltage Vrms Conductor-to-Conductor Conductor-to-Shield | 1500 1000 |

| Jacket Material | FEP |

| Jacket Color | Black |

| Conductor | Silver-Plated Copper Alloy |

| Conductor Color-Coding | Black/White Stripe, Blue/White Stripe, Green/White Stripe, Solid White |

| Dielectric Material | Expanded PTFE |

| Temperature Range °C | -65 to +200 |

Complete the short form below for instant access to a selected drawing with technical specifications from W. L. Gore & Associates.

GORE Fibre Channel Cables have undergone substantial qualification testing to ensure they meet the most current aerospace and defense standards, including:

- ABD0031 (AITM 2.0005); BSS7230; FAR Part 25, Appendix F, Part I: Flammability

- ABD0031 (AITM 3.0005); BSS7239: Toxicity

- ABD0031 (AITM 3.0008B); BSS7238; FAR Part 25, Appendix F, Part V: Smoke Density

- ANSI/NEMA WC 27500: Environmental Testing, Jacket and Marking

- ANSI X3.303: Fibre Channel Physical and Signaling Interface-3 (FC-PH-3)

- EN3475-503: Test Methods for Scrape Abrasion

- SAE AS4373™: Test Methods for Insulated Electric Wire (Contact Gore for available data)

GORE Fibre Channel Cables for avionics are available in a standard size 26 AWG.

RCN8328

Featured Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 455 4684

Have questions or unique requirements?

Our experts are here to guide you.