GORE® Ultraclean Static Round Cables and Assemblies for Lithography

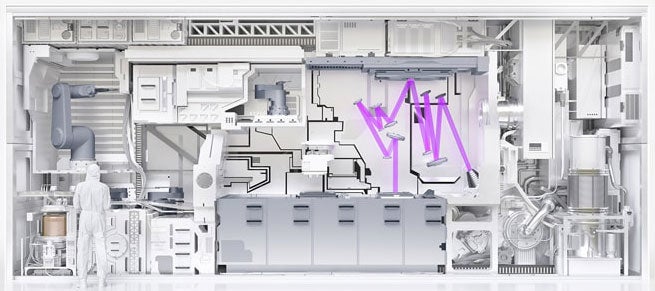

Our Cleanliness Grade 1 solution is developed and validated to meet the semiconductor industry’s rigorous EUV requirements for purity, reliability and signal integrity.

Unmatched Cleanliness, Durability and Performance

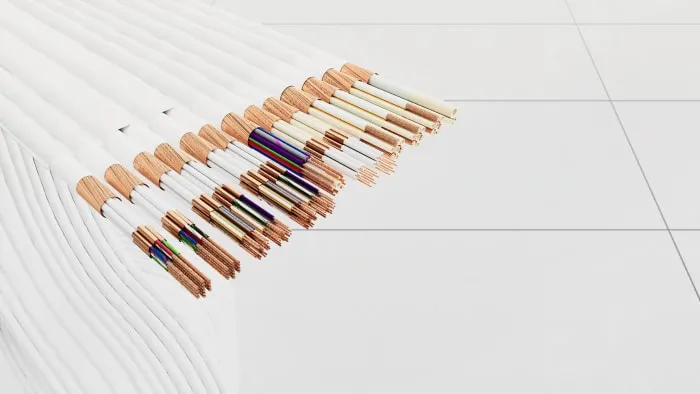

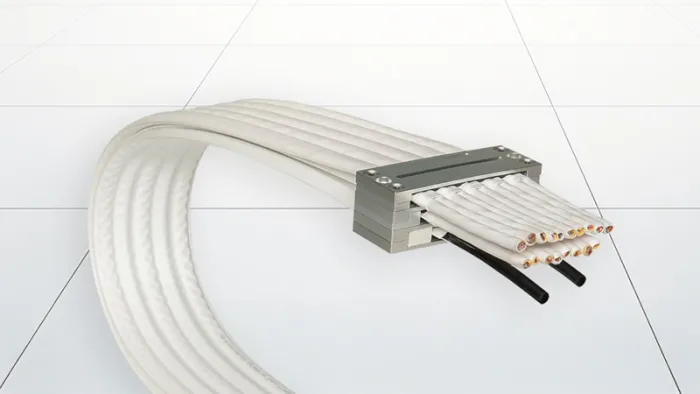

GORE® Ultraclean Static Round Cables and Assemblies offer greater precision and cleanliness for more extreme miniaturization and greater reliability for higher yield, quality and speed. They achieve higher data rates with better signal integrity over longer distances, along with precise, reliable terminations in high-purity lithography processing and high-vacuum applications.

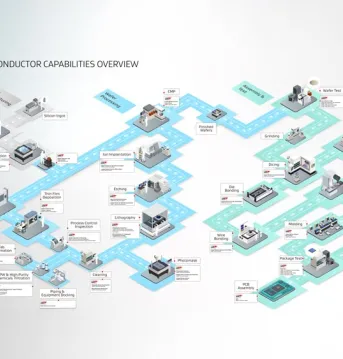

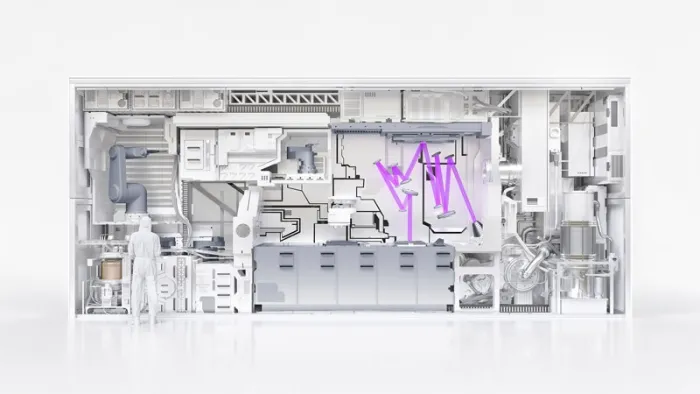

Gore Technologies Offer Improvements Throughout Semiconductor Manufacturing Processes

See where our broad capabilities and solutions are used in many critical processes — from lithography, wafer cleaning, and metrology & inspection to advanced packaging, SoC testing and more.

Technical Information

These values demonstrate the mechanical and environmental performance of GORE Ultraclean Static Round Cables for lithography.

| Mech./Environ. Property | Value |

|---|---|

| Jacket Material | PTFE & Fluoropolymer |

| Jacket Color | White & Opaque |

| Core Types | Signal & Power |

| Minimum Bend Radius | > 10 x OD |

| Temperature Rangea °C | -20 to +260 |

| Cleanliness Class (ISO14664-1) | 1 |

| Outgassing mBar liter/sec cm2 | |

H20 (AMUb 18) | 6.00E-10 |

CxHyv (volatile CxHy) (AMUb 45-100) | 2.00E-12 |

CxHynv (non-volatile CxHy) (AMUb 101-200) | 5.00E-13 |

| Hydrogen-Induced Outgassing (HIO) | Applicable |

| Forbidden Materials | Applicable |

| Particle-Free | Applicable |

| Certifications | UL |

a. Dependent on specific application requirements.

b. AMU = Atomic Mass Units.

Featured Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 294 4673

+1 410 506 1715

Have questions or unique requirements?

Our experts are here to guide you.