GORE® Ozonation Modules for Semiconductor & Microelectronics Processing

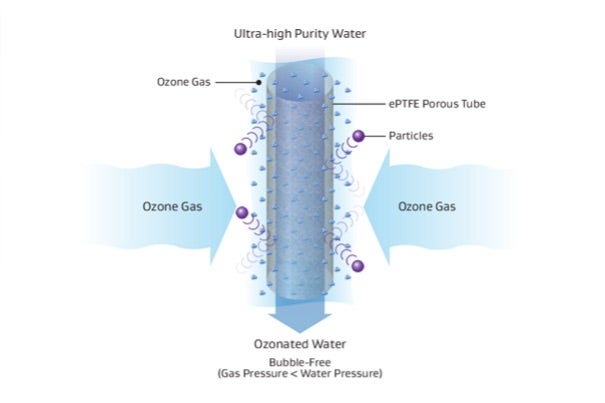

Gore's modules generate the cleanest, bubble-free, highest concentration ozone water for cleaning silicon wafers and semiconductor and FPD fabrication processing.

The Cleanest, Bubble-Free Ozone Water Solution

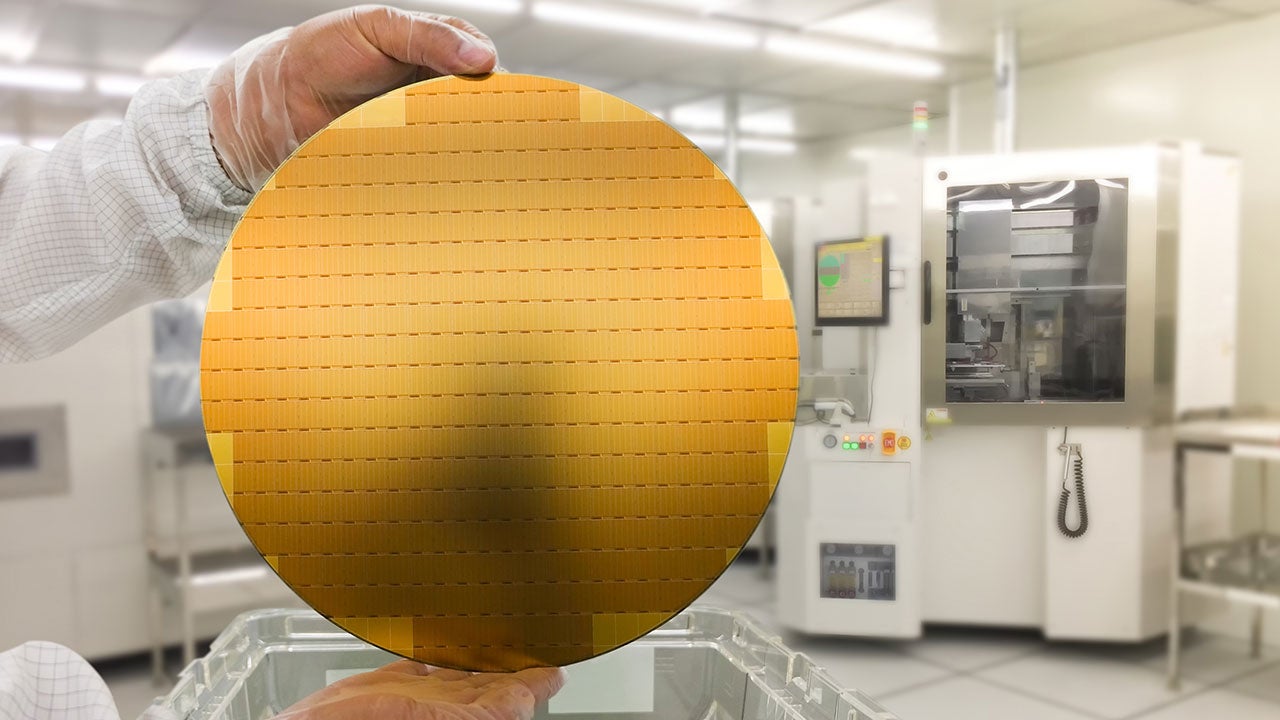

GORE® Ozonation Modules are successfully used in an ozone water-based wafer cleaning tool for silicon wafer and semiconductor applications. They provide a safer and more effective treatment using deionized ozone water (DI-O3 water) than commonly used methods involving harsh chemicals and many semiconductor cleaning process steps.

Gore Technologies in Semiconductor Manufacturing Processes

With decades of unique materials science technology and in-depth application knowledge, Gore offers proven solutions that ensure cleanliness, durability and reliability.

GORE Ozonation Modules for Semiconductor & Microelectronics Fabrication Processing

Ozone-dissolving modules from Gore are the proven, reliable solution for improved semiconductor and microelectronics cleaning process performance and yield.

Technical Information

These values demonstrate the characteristics of GORE Ozonation Modules for semiconductor and microelectronics processing.

| Property | Gore Part Number | |

|---|---|---|

| GN-142-300 | GN-142-650 | |

| Length (Flange-to-Flange) mm | 300 | 650 |

| Diameter mm | 142 | 142 |

| Membrane Material | Expanded PTFE | Expanded PTFE |

| Housing Material | PTFE/PFA | PTFE/PFA |

| Ozone Concentration ppm | Up to 200 | Up to 200 |

| Water Entry Pressure (WEP) MPa | > 0.40 | > 0.40 |

| Maximum Liquid Pressure MPaG | 0 to 0.35 | 0 to 0.35 |

| Maximum Gas Pressure MPaG | 0.25 | 0.25 |

| Recommended Operating Temperature °C | 0 to +30 | 0 to +30 |

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 346 7391

Have questions or unique requirements?

Our experts are here to guide you.