GORE Cable Protective Braids

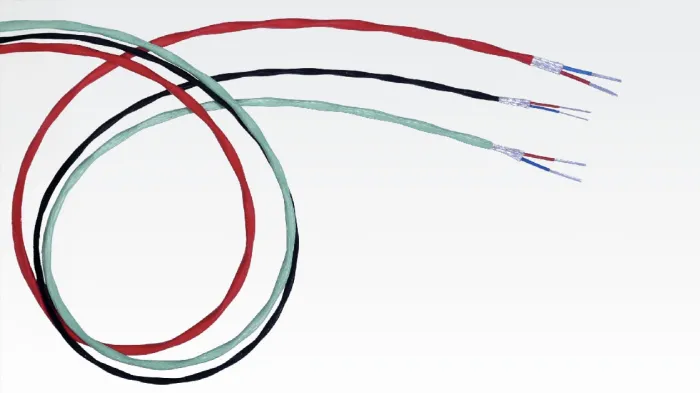

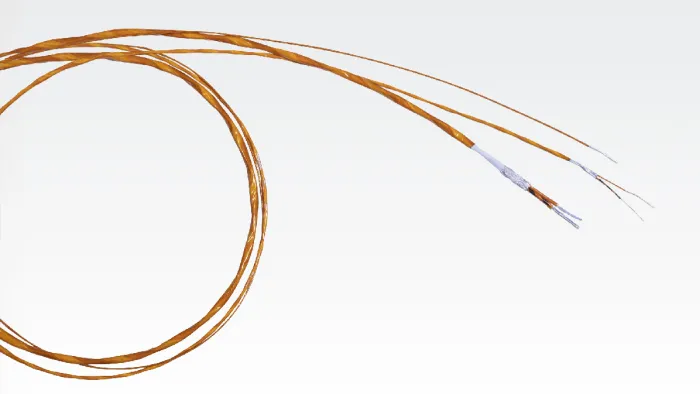

Our space cable braids provide durable protection in extreme temperatures and enhance EMI suppression for reliable signal integrity while enabling tight installations.

Durable Protection from Spacecraft Temperature Extremes

GORE Cable Protective Braids installed over our space cable bundles protect sensitive wires from extreme temperatures and enhance EMI suppression, ensuring reliable signal integrity. Our high-strength braids are also smaller and more flexible than competitors for easier routing in tight spacecraft areas.

Gore Solutions for Spaceflight

Watch and learn how Gore can help solve the design challenges inherent in space missions, providing decades of proven, reliable solutions to space companies.

Technical Information

GORE Cable Protective Braids meet these technical specifications:

| Braid Type | Plating µm min. | Operating Temperaturea °C |

|---|---|---|

| ePTFE | N/A | -200 to +260 |

| Copper | Silver (2.5) | -200 to +200 |

| Copper | Nickel (1.2) | -200 to +260 |

| ePTFE over Copper | Silver (2.5) | -200 to +200 |

| ePTFE over Copper | Nickel (1.2) | -200 to +260 |

a. For dynamic flex applications, the minimum operating temperature is -100°C.

GORE Cable Protective Braids are available in a variety of diameter sizes. Examples of our part numbers include the following:

| Braid Type | OD in (mm) | ID in (mm) | Braid Coverage % | Gore Part Number |

|---|---|---|---|---|

| ePTFE | 0.236 (6.0) | 0.197 (5.0) | 99 | GSC-05-1401-00 |

| ePTFE | 0.433 (11.0) | 0.394 (10.0) | 97 | GSC-05-1403-00 |

| ePTFE | 0.630 (16.0) | 0.591 (15.0) | 96 | GSC-05-1404-00 |

| Silver-Plated Copper | 0.138 (3.5) | 0.118 (3.0) | 90 | GSC-05-82051-00 |

| Silver-Plated Copper | 0.177 (4.5) | 0.157 (4.0) | 90 | GSC-05-82052-00 |

Featured Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 455 4684

Have questions or unique requirements?

Our experts are here to guide you.