GORE® GFO® Packing Fiber

The right packing for reliability and savings, GORE® GFO® Packing Fiber is engineered for high performance and longer in-service lifetime with less frequence maintenance cycles.

High-Performance General Service Packing

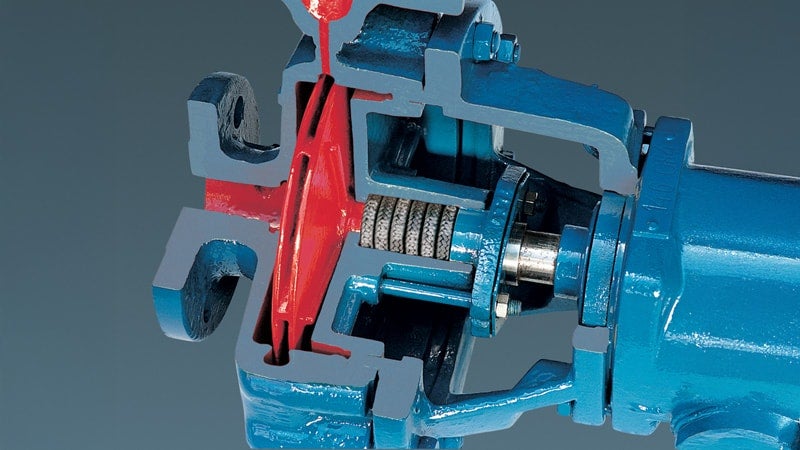

Packings with 100% GORE GFO Packing Fiber can provide maintenance engineers with consistently high-performance general service packing for wide application and use, including sealing shafts on high-speed pumps, mixers, agitators, or any other equipment with rotating or reciprocating shafts. It doesn’t become hard or brittle, is temperature and chemically tolerant and easy to install and remove.

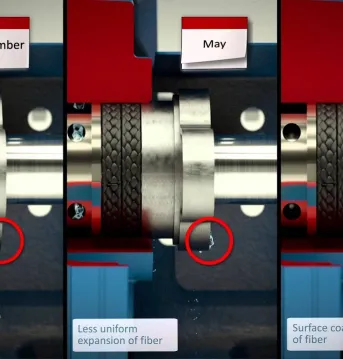

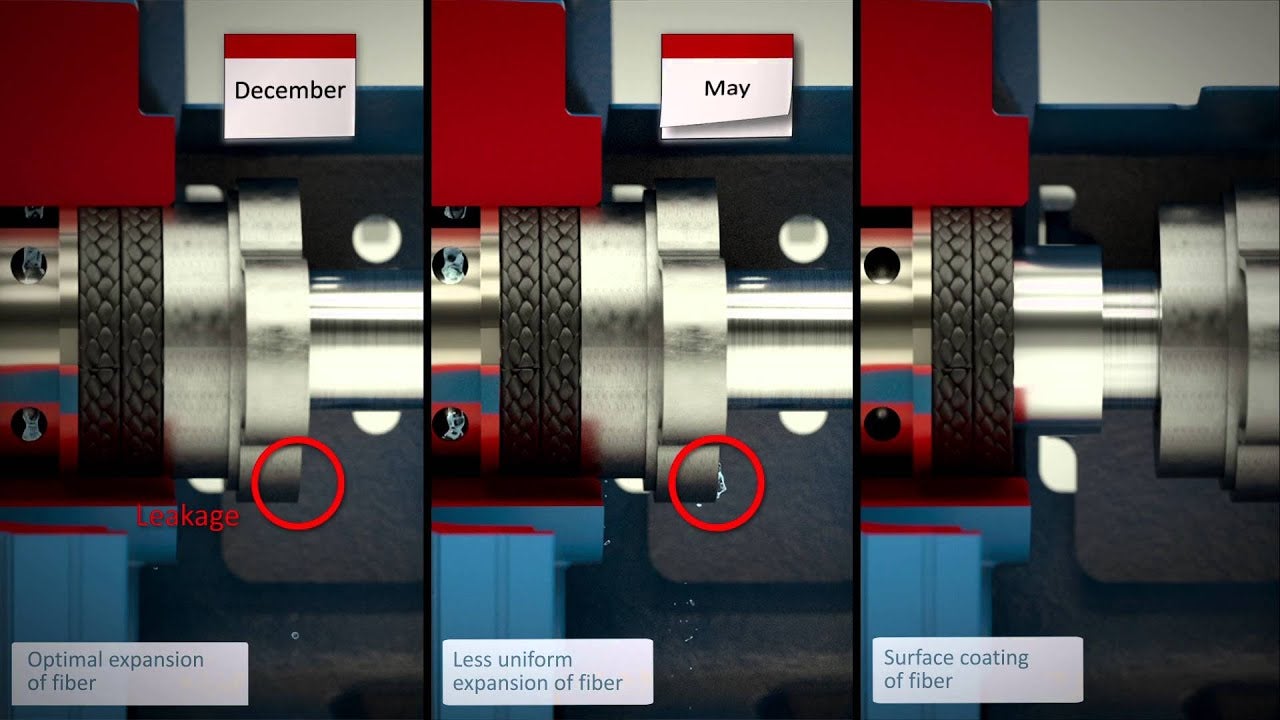

Leakage differences between compression packings

See the leakage rate difference between a packing made with 100% GORE GFO Fiber versus a generic PTFE/graphite packing.

Leak Rate: Gore vs. Generic Packing

Would you rather lose droplets, or a steady stream?

Technical Information

| Temperature Range | -240°C to +288°C (-400°F to +550°F) |

|---|---|

| Chemical Resistance | Chemically inert, with few exceptions, over the entire 0-14 pH range. |

| Stability | Able to withstand shaft speeds to 4,300 feet per minute (21.8 m/s). |

Braid Density

The yield figures below are representative of satisfactory braided packing made of 100% GORE GFO Fiber. The data serves as a working guideline only and not as a minimum quality standard.

| Braided Packing Cross Section | Yield | ||

|---|---|---|---|

| in | mm | ft/lb | m/kg |

| 1/8 | 3.18 | 80.00 | 53.64 |

| 3/16 | 4.76 | 38.00 | 25.48 |

| 1/4 | 6.35 | 23.00 | 15.42 |

| 5/16 | 7.94 | 15.00 | 10.06 |

| 3/8 | 9.50 | 11.00 | 7.38 |

| 7/16 | 11.11 | 8.00 | 5.36 |

| 1/2 | 12.70 | 6.00 | 4.02 |

| 9/16 | 14.29 | 5.00 | 3.35 |

| 5/8 | 15.88 | 4.00 | 2.68 |

| 11/16 | 17.46 | 3.20 | 2.14 |

| 3/4 | 19.05 | 2.80 | 1.88 |

| 7/8 | 22.26 | 2.00 | 1.34 |

| 1 | 25.40 | 1.50 | 1.00 |

Braid Dimensional Tolerances

Another significant factor affecting braided packing performance is the degree to which it is properly sized. Calendaring braid and die-forming rings are two effective ways that the manufacturer can produce packing that closely adheres to dimensional specifications. The Fluid Sealing Association recommends the following tolerances.

| Cross Section | Tolerance |

|---|---|

| To 1/4 in | +/- 1/64 in |

| To 6 mm | +/- 0.4 mm |

| 1/4 in to 1 in | +/- 1/32 in |

| 6 mm to 25 mm | +/- 0.8 mm |

| Greater than 1 in | +/- 1/16 in |

Cetim EN 16752 Test Results

Cetim has performed testing on packing made of 100% GORE GFO Fiber using the EN 16752 "Centrifugal pumps – Test procedure for seal packing."

Test Protocol

- Ambient temperature

- Test medium: clean water

- 50 mm shaft diameter, 1500 & 3000 rpm

- Pressure: steady 0.6 MPa

- Loading: After 2 hours 1.8 kN, <1.5 kN 2nd & subsequent adjustments to 1.6–1.8 kN

Shaft Leak Rate

After initial break in stabilization, 3000 rpm.

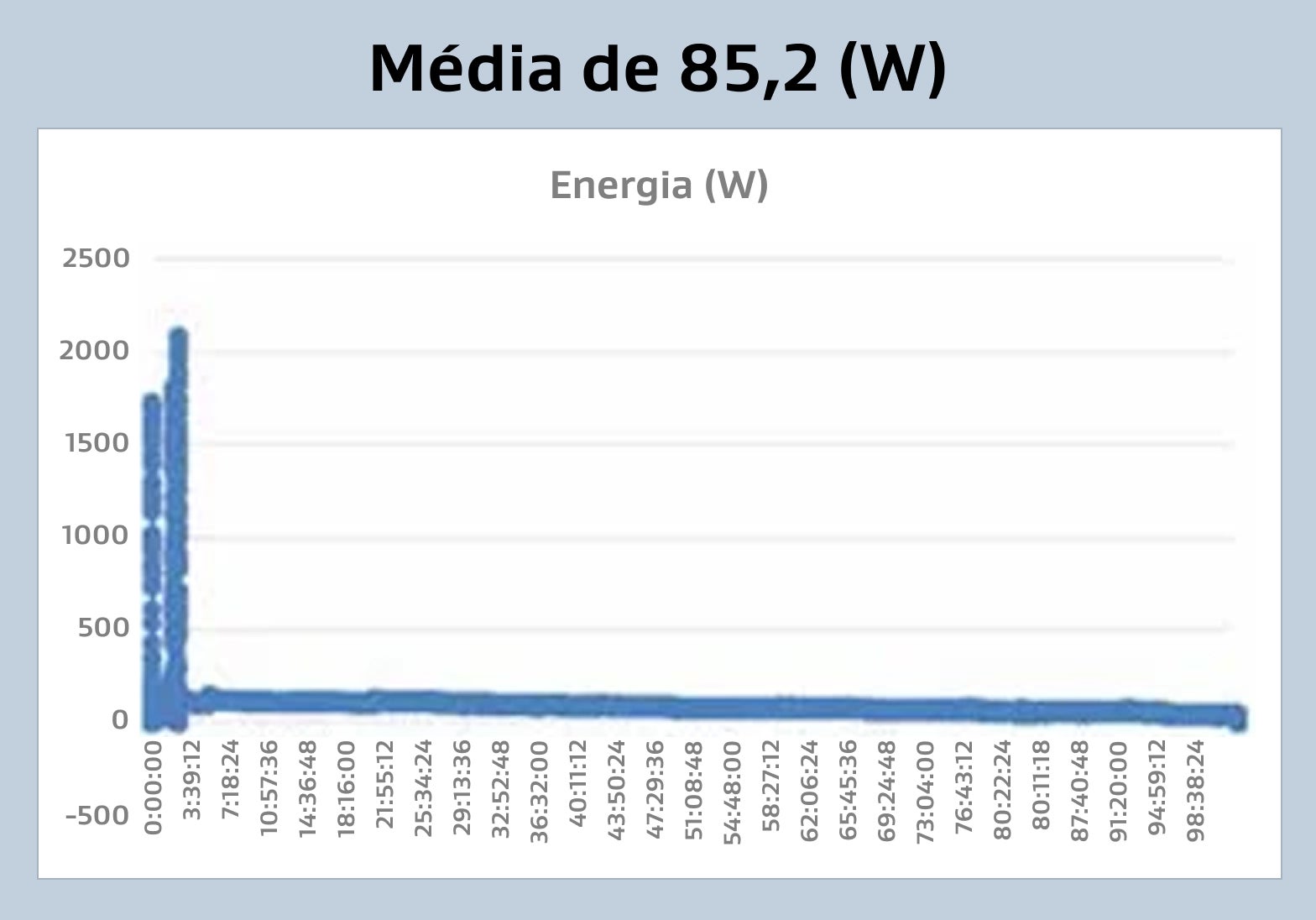

Power Consumption

After initial break in stabilization, 3000 rpm.

More information on the Cetim test procedure can be found here.

Case Study

Related Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 542 3146

Have questions or unique requirements?

Our experts are here to guide you.