GORE® Cover for Composting, Organic Resource Recovery, Bio-Drying & Stabilization

GORE® Cover is proven technology for composting organics from green waste, residential / commercial food, biosolids, animal processes (bedding, litter, manure), anaerobic digestate residuals and stabilization of municipal solid waste organics.

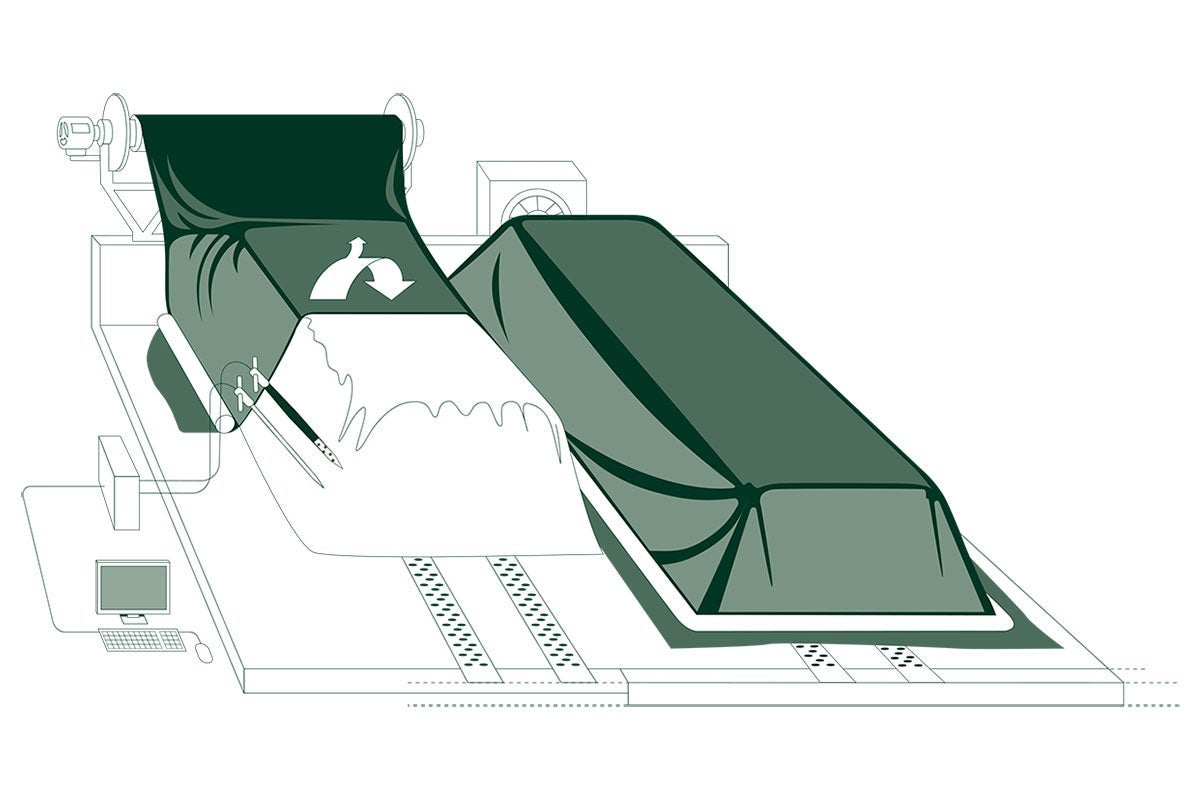

More than a cover – it’s a complete system

GORE® Cover is a proven technology for aerobic composting using an engineered semi-permeable membrane combined with a positive direction aerated system.

Controlled intermittent flow of air is introduced by specially designed controllers with temperature and oxygen feedback monitoring probes. By sealing the GORE® Cover with perimeter weighting or bunker fastening system, the GORE® Cover is pressurized to acing a true vessel to evenly distribute air and moisture to all areas of the organic material being processed.

The GORE® Cover system approach creates an ideal composting conditions to efficiently capture odors, VOC emissions while optimizing moisture management in the process. This results in higher throughput on smaller footprint and lower energy consumption with less human in operator involvement.

Technical Specifications

Feed Stocks and Typical Organic Material Handling

From yard waste to food waste, from green cuttings to digestate, from source separated organics to manure, from catering waste to paper sludge, from fish waste to slaughterhouse waste: There is few organic waste we can think of that has not been successfully treated with the GORE® Cover system. In every case the system has proved its flexibility, has never caused complaints about odor emissions and always delivers high class compost for a successful marketing approach.

As a result of an increasing number of waste water plants there is a strong trend towards the composting of biosolids. Whilst compost from biosolids offers a lot of environmental benefits, processing the input material is challenging (it has a high moisture content, is rich in nitrogen, contains potential pathogens) and requires a high degree of process control.

The key to successful MSW treatment is volume and moisture reduction to achieve landfill criteria as defined by national regulations. Alternatively Refuse Derived Fuel (RDF) can be produced to generate energy from waste.

Within this context the GORE® Cover system is ideal as fully capable stand-alone solution for processing pre-screened MSW. But it has also been proven to solve troublesome odor issues when curing MSW which was initially treated in a tunnel system.