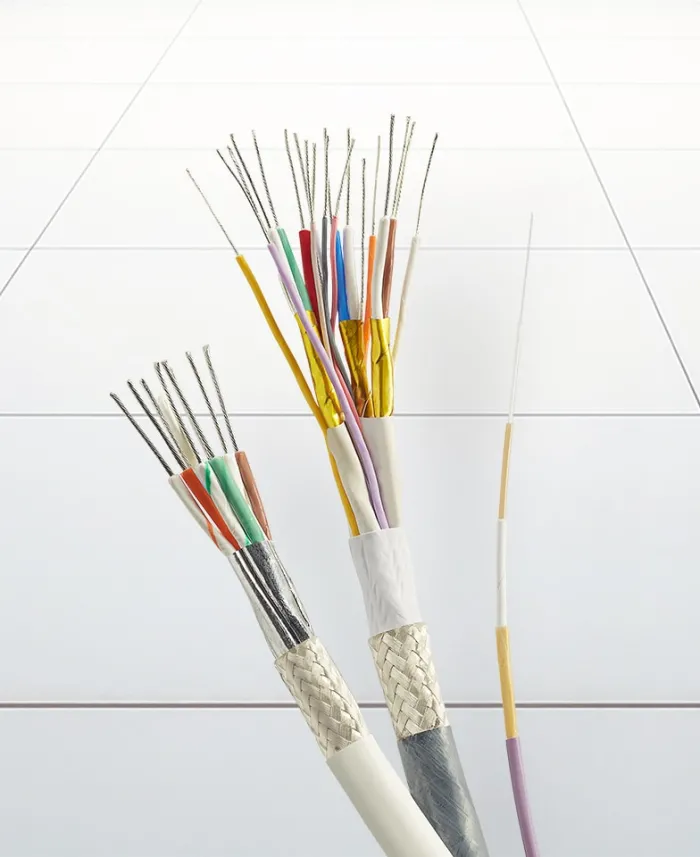

Hybrid Round Cable for Harsh Environments

GORE® Hybrid Round Cable is electrically and mechanically optimized for high performance in difficult applications.

Optimized for Performance

Our Hybrid Round Cable for Harsh Environments offers rugged features, robust environmental protection, and high EMI/RFI shielding capabilities that are available for industrial applications with stringent performance envelopes.

Technical Information

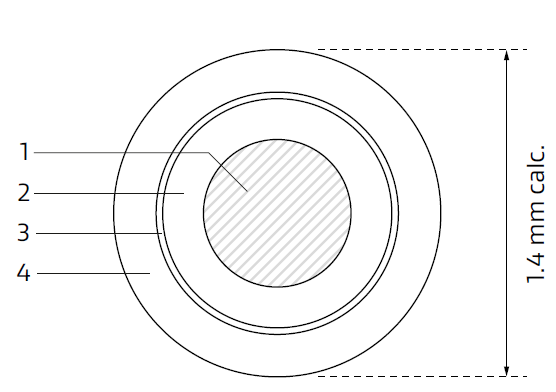

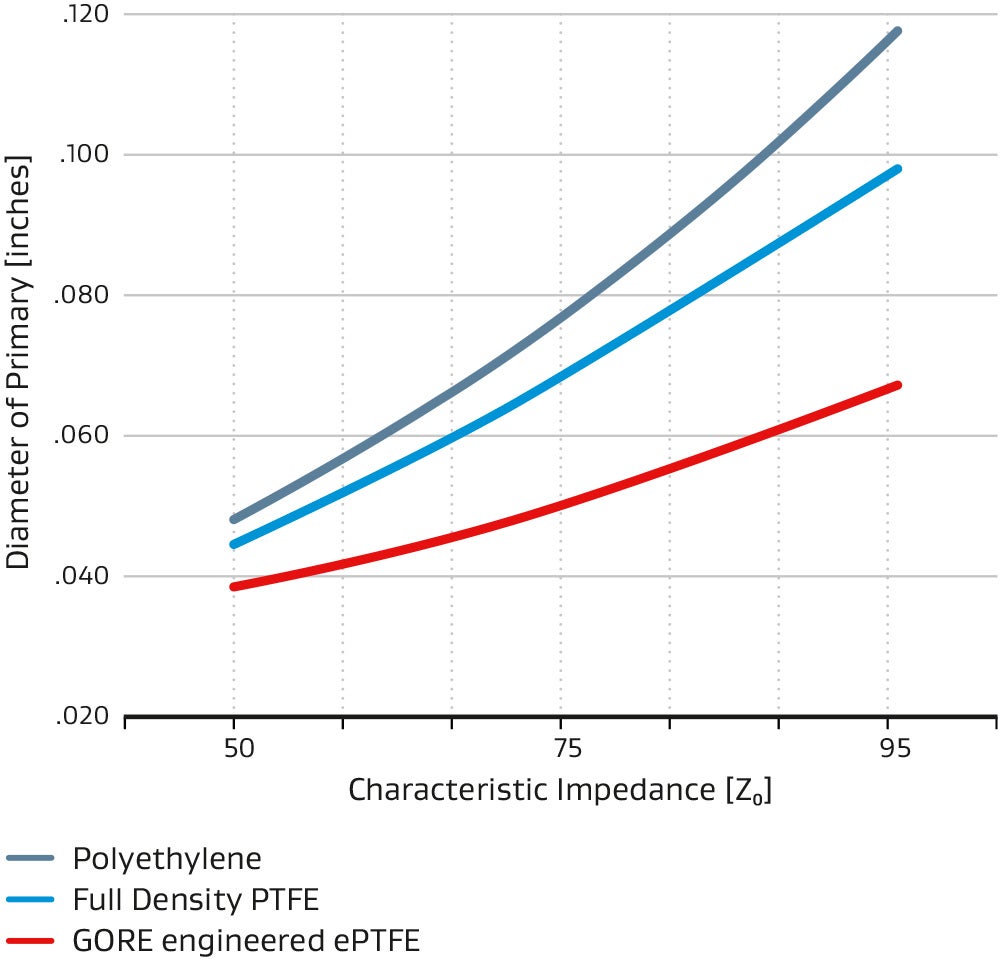

Because Gore ePTFE insulation has a low dielectric constant, less of it is used in Gore cables, reducing the overall size and weight of the interconnect. With possible weight savings as high as 70 percent, Gore round-cable assemblies are ideal for space and airborne applications and computer systems that require high-density interconnects.

MIL-ENE insulation is an extremely tough, thin polyester laminate. This high-modulus insulation has a unique load-sharing ability that increases the strength of the conductor.

It also protects the conductors from cut-through better than any other flexible insulation. This increase in strength allows use of smaller gauge conductors in many applications where larger conductors have been specified for mechanical strength only.

A tough, thin primary insulation means a smaller cable, and a smaller cable means significantly more flexibility (because the bending ease of a bundle of wires is inversely proportional to the fourth power of the radius of the cable). For example, a 50 percent smaller cable is 94 percent more flexible.

The best performing coil cords are made of smaller cables. Gore coil cords have excellent retentive memory, long flex life, and long-term reliability. They perform longer and better in the most demanding applications.

Featured Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 866 271 5954

Have questions or unique requirements?

Our experts are here to guide you.