Industrial Fluids Filtration Solutions

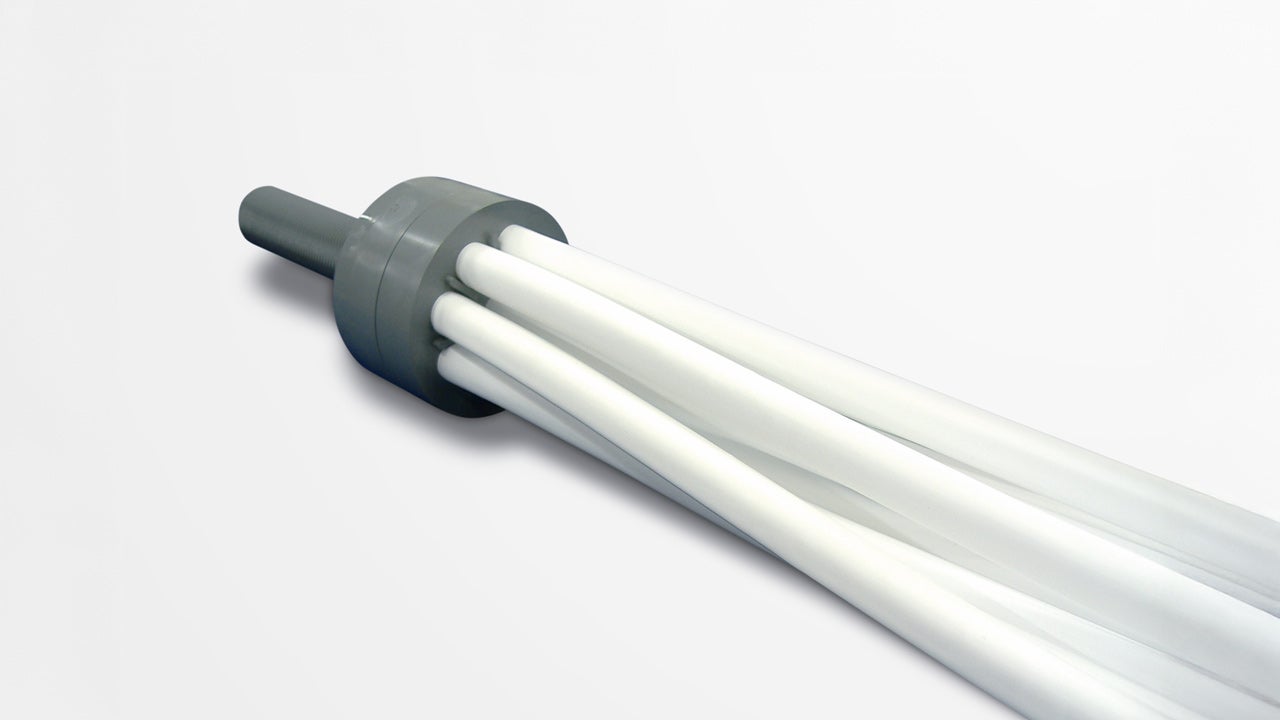

GORE Membrane Filter Sock and Tube Assemblies provide highly efficient ePTFE membrane filtration for use in tubular backpulse liquid filtration systems.

Reduce Capital and Operating Expenses with Gore One-Step Filtration

GORE Membrane Filter Sock and GORE Filter Tube Assemblies provide excellent separation efficiency and economical performance in high flow rate and/or high feed solids applications through membrane filtration.

Featured Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 654 4229

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.