GORE® ePTFE Fiber and Filament

GORE® ePTFE Fiber and Filament offer advanced performance in demanding applications through revolutionary fiber technology.

Exceptional Performance in Challenging Environments

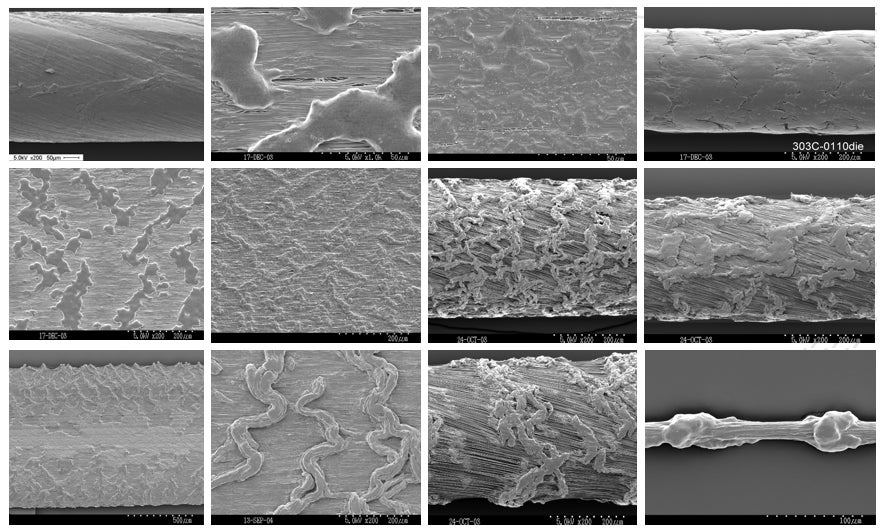

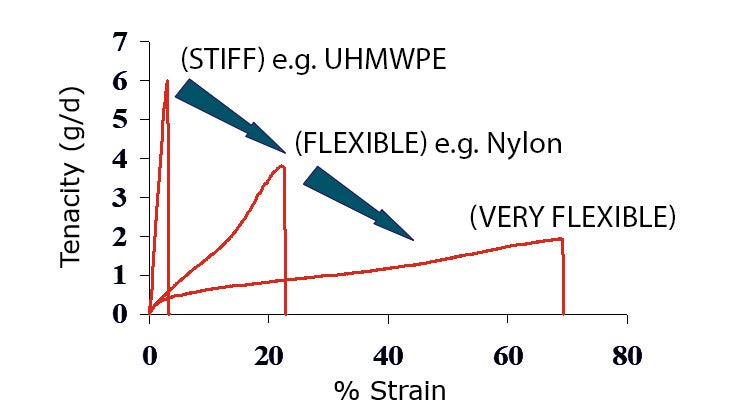

GORE® ePTFE Fibers and Filaments are engineered to offer exceptional performance in a range of challenging environments. Designed to meet the highest industry standards, these fibers and filaments are versatile, tough and abrasion resistant while maintaining tensile strength.

Tensile strength, modulus (stiffness), density, surface texture, additive capability such as color and other required attributes are designed into GORE® Fibers and Filaments to provide unique solutions with one single fiber material. The fiber can be sewn, knitted or woven into various structures, and combined with other yarn material to achieve the desired properties of the finished product.

Technical Information

Performance Properties

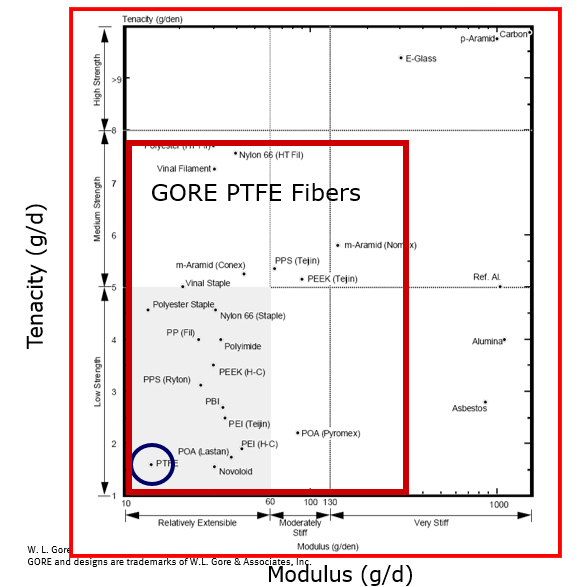

A unique combination of properties and the most comprehensive portfolio of product attributes make GORE Fibers the best choice for a wide variety of critical applications.

| GORE™ ePTFE Fiber Properties | |

|---|---|

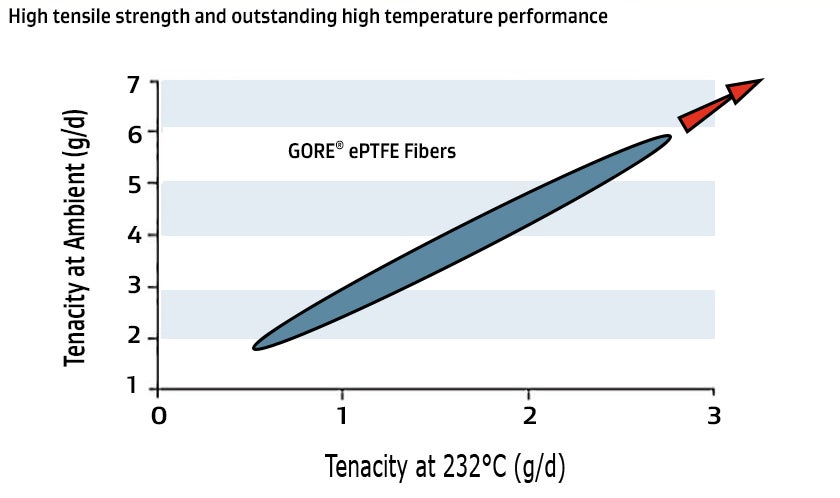

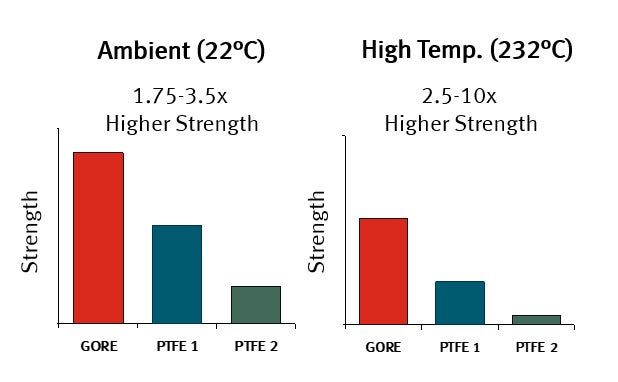

| Tenacity | up to 7 grams/denier (62cN/tex) |

| Tenacity at 200°C | up to 2.5 grams/denier (22cN/tex) |

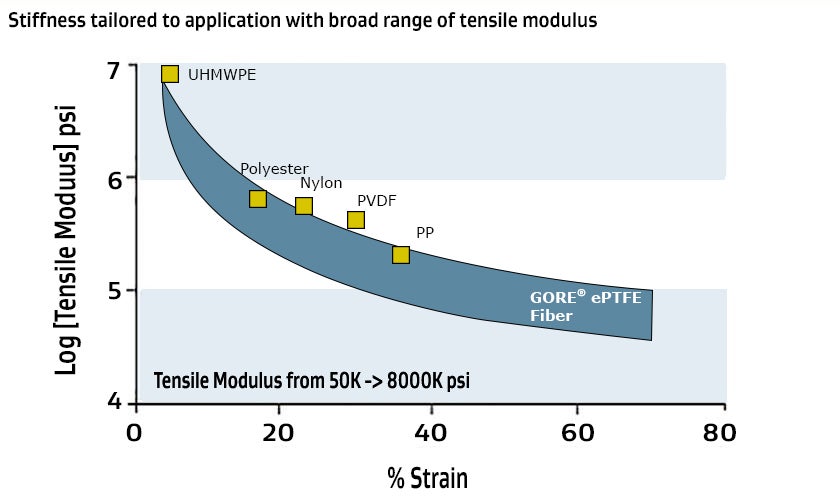

| Modulus | 50–8000 ksi |

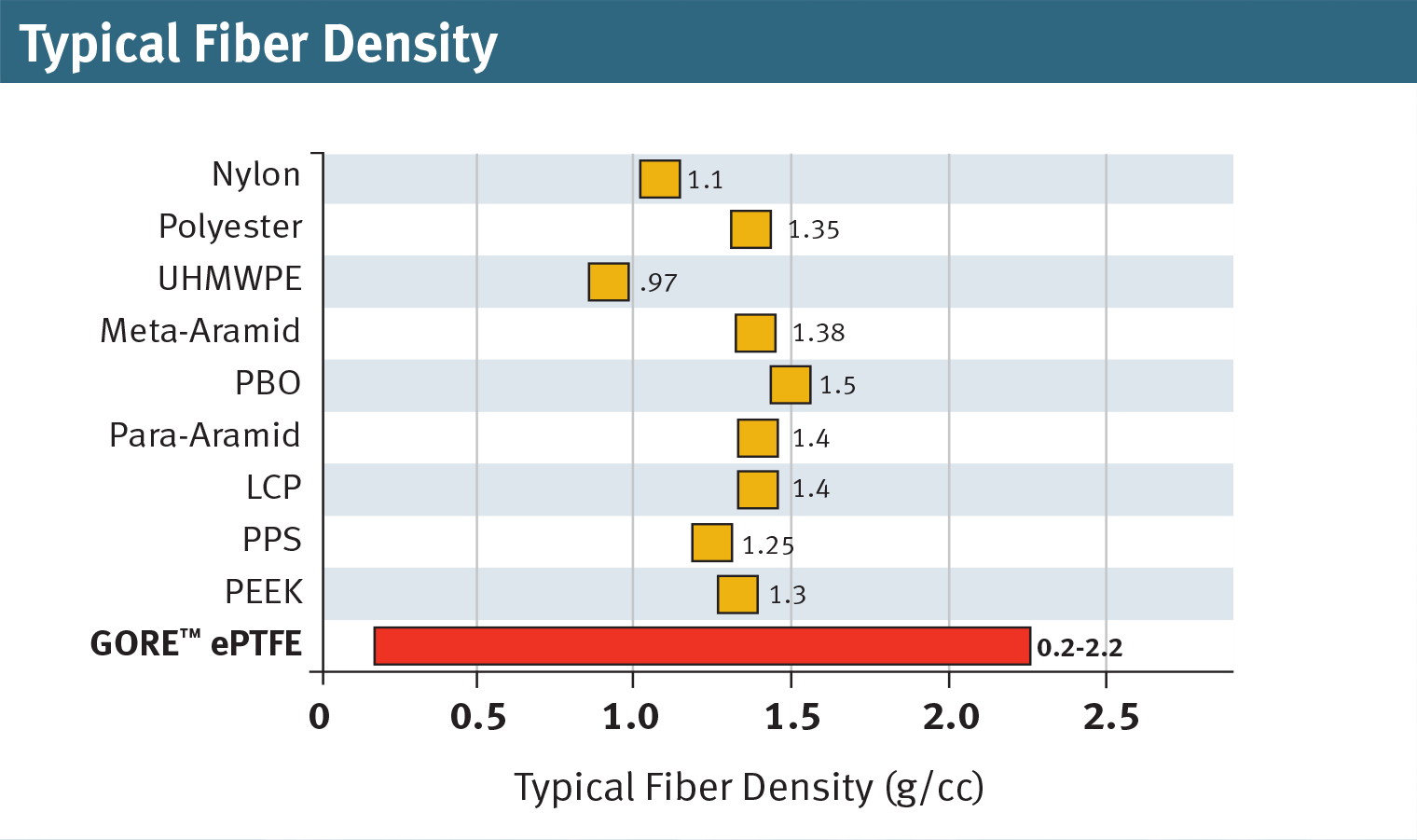

| Density | 0.2–2.2 grams/cc |

| Melting Point | 340°C |

| Coefficient of Friction | 0.01–0.04 |

| Flex Endurance (MIT) | >10E6 cycles |

| Thermal Conductivity | 0.1–0.3 W/mK |

| Thermal Conductivity (filled) | 1.5 W/mK |

| Volume Resistivity (filled) | >1 Ohm-cm |

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 276 8451

Have questions or unique requirements?

Our experts are here to guide you.