GORE® MIL-STD-1760 Assemblies for Defense Aircraft

The only sealed hybrid solution proven over time to solve common challenges with aircraft pylon installation and critical operations at a cost you can afford.

Affordable, Easy to Install, Flight Proven

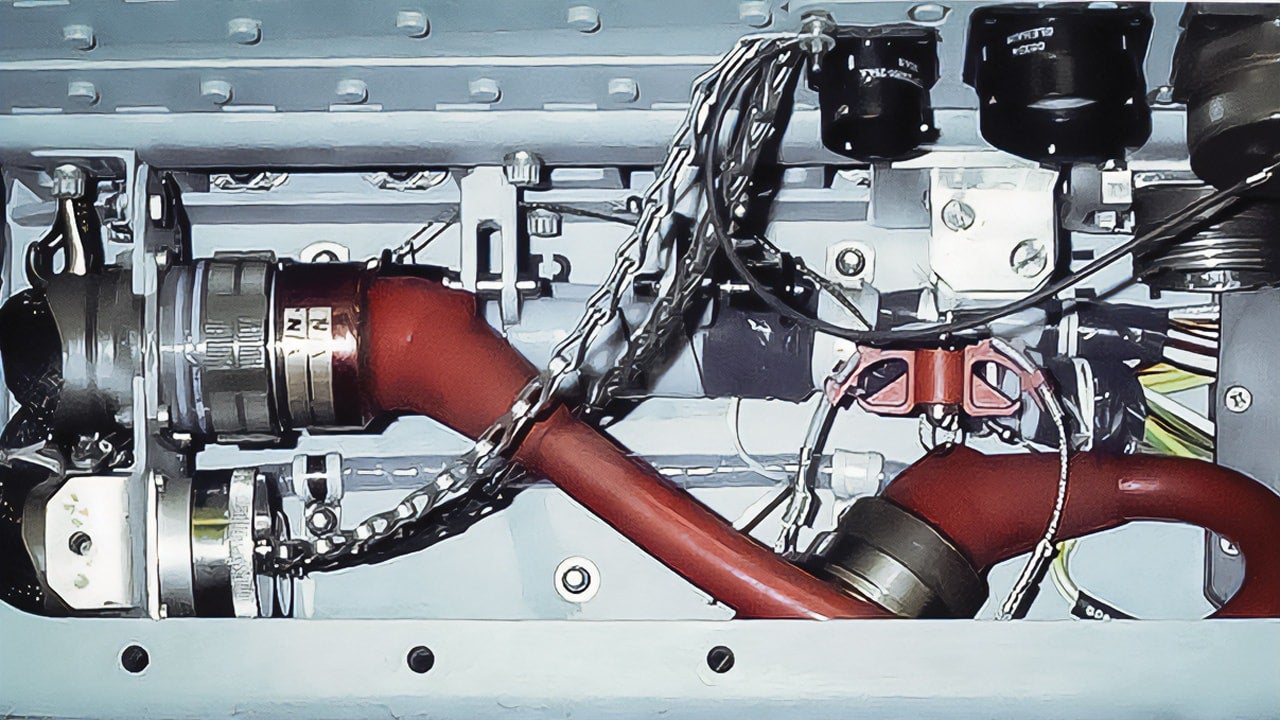

Robust, highly flexible GORE® MIL-STD-1760 Assemblies with the L3 Harris connector system deliver consistent disconnect loads and can guarantee 100 fully high-speed instrumental drops. They can be easily installed in tight pylon spaces and are flight-proven on many military aircraft platforms, making them an ideal replacement for standard umbilical assemblies.

Technical Information

These values demonstrate the mechanical and environmental performance of GORE MIL-STD-1760 Assemblies for defense aircraft.

| Mechanical / Environmental Property | GSC-01-86039-00 Class I (FO) | GSC-01-86038-00 Class I | GSC-01-85806-00 Class II |

|---|---|---|---|

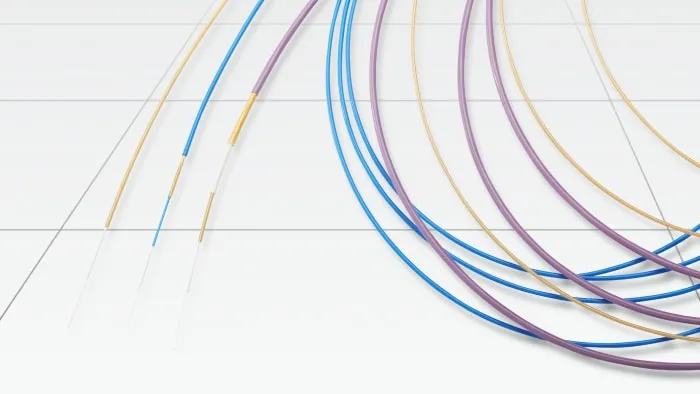

| Outer Jacket Material | Halogen-Free Elastomer | Halogen-Free Elastomer | Halogen-Free Elastomer |

| Outer Jacket Colora | Black | Black | Black |

| Conductor Platingb | Silver-Plated Copper | Silver-Plated Copper | Silver-Plated Copper |

| Conductor Color-Coding | Individually Coded Primaries | Individually Coded Primaries | Individually Coded Primaries |

| Dielectric Material | Expanded PTFE/ PTFE | Expanded PTFE/ PTFE | Expanded PTFE/ PTFE |

| Braid Shieldingb | Silver-Plated Copper | Silver-Plated Copper | Silver-Plated Copper |

| Braid Optical Coveragec % | > 85 | > 85 | > 85 |

| Outer Diameter mm (in) | 18.7 (0.74) | 18.7 (0.74) | 18.3 (0.72) |

| Fiber Optic Core Typeb | OM3 (Multi-Mode, Graded Index) | — | — |

| Fiber Optic Core/Cladding/Coating | 50/125/245 | — | — |

| Fiber Optic Buffering System | Expanded PTFE 900 micron | — | — |

| Minimum Bend Radius mm (in) Static Dynamic | 46.8 (1.8) 93.5 (3.7) | 46.8 (1.8) 93.5 (3.7) | 45.8 (1.8) 91.5 (3.6) |

| Flex Life Cycles | > 100,000 | > 100,000 | > 100,000 |

| Temperature Range °C | -60 to +150 | -60 to +150 | -60 to +150 |

a. Other jacket colors available upon request.

b. Other options available upon request.

c. Other optical coverages available upon request.

Safeguard your defense aircraft mission with GORE MIL-STD-1760 Assemblies available in the following standard part numbers.

GSC-01-86038-00 Class I

GSC-01-86039-00 Class I (FO)

GSC-01-85806-00 Class II

We also offer bespoke and custom assembly options with MIL-STD backshells, custom backshells, and molding designs to meet your specific aircraft integration requirements.

Featured Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 455 4684

Have questions or unique requirements?

Our experts are here to guide you.