GORE® CAN Bus Cables for Aerospace & Defense

Our rugged, flexible cables ensure fast, accurate data transmission in next-gen avionics and vetronics while simplifying routing and installation.

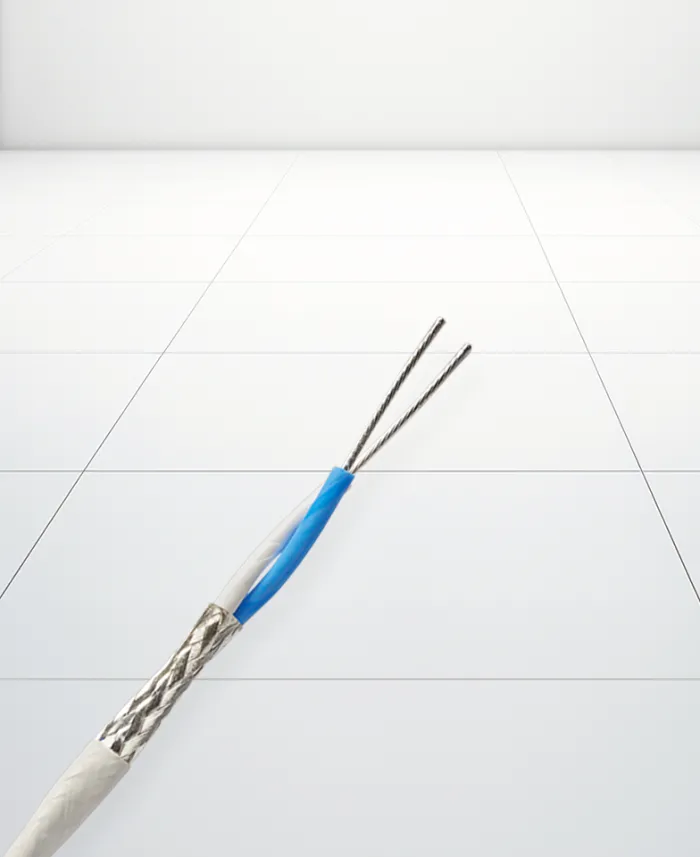

Controlled-Impedance Cables Provide High-Quality Signals

Built for speed and accuracy, GORE® CAN Bus Cables reliably send high-quality signals for secure data transmission up to 1 GHz while maintaining 120-ohm controlled impedance. Our cables endure whatever conditions they encounter, from rapid temperature changes and repeated vibration to trouble-free routing.

GORE® High Speed Data Cables for Aerospace & Defense

Combining dielectric expertise with innovative fluoropolymer materials, we bring a portfolio of standard high data rate cables with proven performance over leading alternatives.

Is High-Speed Data Transmission in Defense Aircraft a System Lifetime or Costly Afterthought?

Watch this free on-demand webinar on this topic and listen to Gore experts share their deep industry knowledge and materials expertise while using real-world examples.

Technical Information

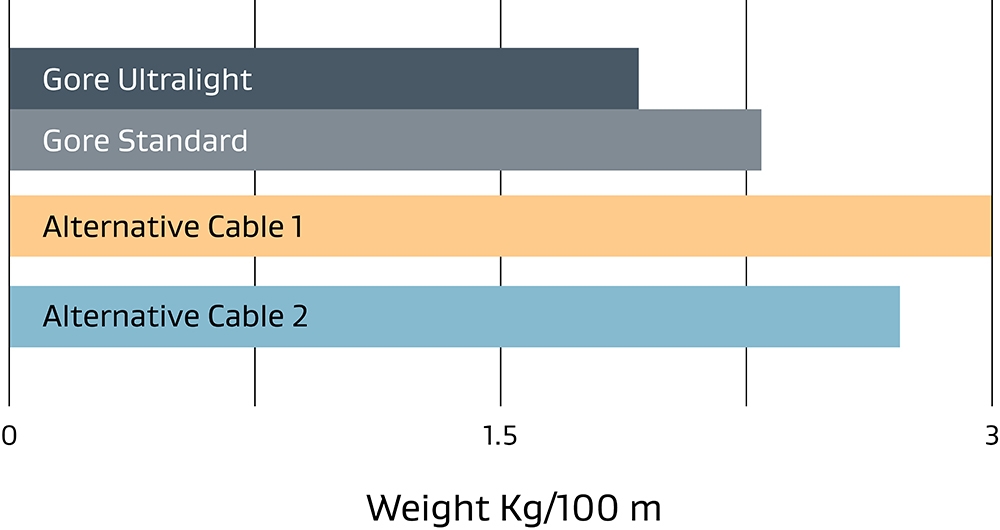

Compare the Ultralight version of GORE CAN Bus Cables against leading alternatives to see how much weight you can save on aircraft and military vehicles.

Cable Type (24 AWG) | Diameter | MBR | Weight | |

|---|---|---|---|---|

g/m (lbs./100 ft.) | kg/100 m | |||

| Gore Ultralight Part Number: DXN2657-24 | 4.2 (0.17) | 21.0 (0.83) | 17.5 (1.18) | 1.8 |

| Gore Standard Part Number: GSC0385752-24D | 4.2 (0.17) | 21.0 (0.83) | 23.0 (1.55) | 2.4 |

| Alternative Cable 1 | 4.7 (0.18) | 25.4 (1.00) | 29.6 (1.98) | 3.0 |

| Alternative Cable 2 | 3.6 (0.14) | 19.3 (0.75) | 26.0 (1.75) | 2.6 |

These values demonstrate the electrical, mechanical and environmental performance of GORE CAN Bus Cables for aerospace and defense.

| Elec./Mech./Environ. Properties | Value |

|---|---|

| Signal Transmission Speed GHz | Up to 1 |

| Standard Impedance Ohms | 120 ± 10 |

| Typical Operating Voltage V | < 48 |

| Nominal Velocity of Propagation % | 80 |

| Nominal Time Delay ns/m (ns/ft.) | 4.10 (1.25) |

| Capacitance pF/m (pF/ft.) | 42.0 (12.8) |

| Dielectric Withstanding Voltage Vrms Conductor-to-Conductor Conductor-to-Shield | 1500 / 700a 1000 |

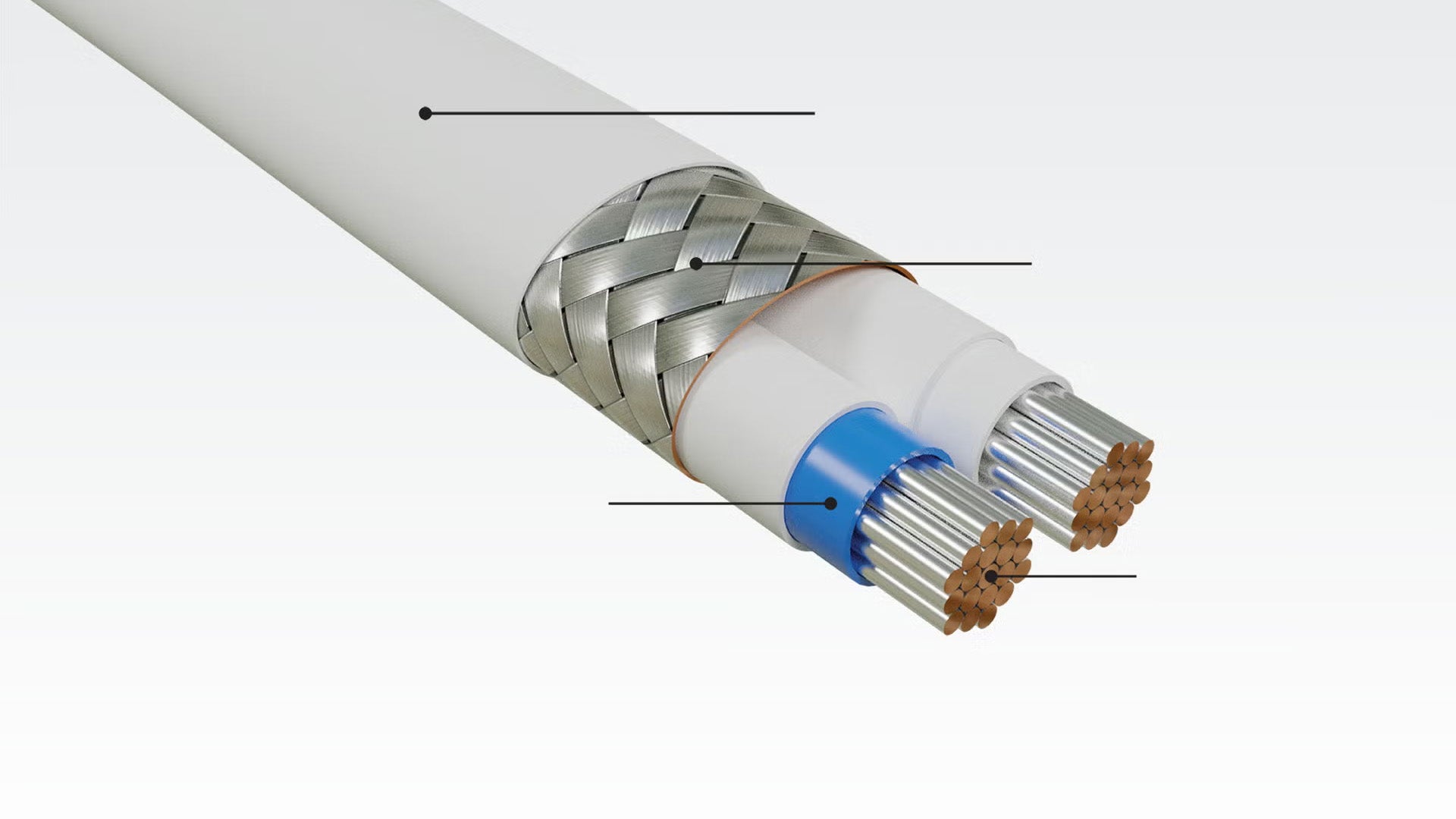

| Jacket Material | Engineered Fluoropolymer |

| Jacket Color | White (Laser Markable) |

| Conductor | Sliver-Plated Copper or SPC Alloy |

| Conductor Color-Coding | Blue/White |

| Dielectric Material | Expanded PTFE/PTFE |

| Temperature Range °C | -65 to +200 |

| Downloads | Standard: Data Sheet Ultralight: Data Sheet |

a. Based on Gore’s part number GSC-03-84793-VG for military vehicle systems.

Complete the short form below for instant access to selected drawings with technical specifications from W. L. Gore & Associates.

With a thorough understanding of products operating in aerospace and defense, GORE CAN Bus Cables are tested and qualified to comply with the following industry standards:

- ABD0031 (AITM 2.0005); BSS7230; FAR Part 25, Appendix F, Part I: Flammability

- ABD0031 (AITM 3.0005); BSS7239: Toxicity

- ABD0031 (AITM 3.0008B); BSS7238; FAR Part 25, Appendix F, Part V: Smoke Density

- ANSI/NEMA WC 27500: Environmental Testing, Jacket and Marking

- SAE AS4373™: Test Methods for Insulated Electric Wire (Contact Gore for available data)

- SAE J1128™: Low Voltage Primary Cable

- SAE J1939™: Serial Control and Communications Heavy Duty Vehicle Network

- VG95218-31: Performance Requirements (GSC-03-84793-VG)

GORE CAN Bus Cables for avionics and vetronics are available in standard sizes.

DXN2657-24 (Ultralight)

DXN2657-26 (Ultralight)

GSC-03-85752-22D

GSC-03-84793-VG

GSC-03-85752-24D

GSC-03-85752-26D

We also offer our cables with an additional drain wire:

GSC-03-86523-00 (24 AWG)

GSC-03-86524-00 (26 AWG)

Featured Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 455 4684

Have questions or unique requirements?

Our experts are here to guide you.