GORE® Abrasion Resistant Cable Jacket for Aerospace & Defense

Our thinner, lighter material meets stricter durability requirements without additional sleeving for the highest abrasion and cut-through resistance to protect copper wires.

Highest Protection for High Data Rate Copper Wires

GORE® Abrasion Resistant Cable Jacket meets new and existing standards for packaging high data rate wires without sacrificing size, weight or signal transmission performance. Made of a revolutionary fluoropolymer fiber material, our rugged jacket eliminates additional protective sleeving for copper wires installed seats.

GORE® High Speed Data Cables for Aerospace & Defense

Combining dielectric expertise with innovative fluoropolymer materials, we bring a portfolio of standard high data rate cables with proven performance over leading alternatives.

Gore Solutions for Aerospace & Defense

Learn more about Gore’s wide range of components and materials that have been time-tested and proven to aerospace and defense suppliers.

Technical Information

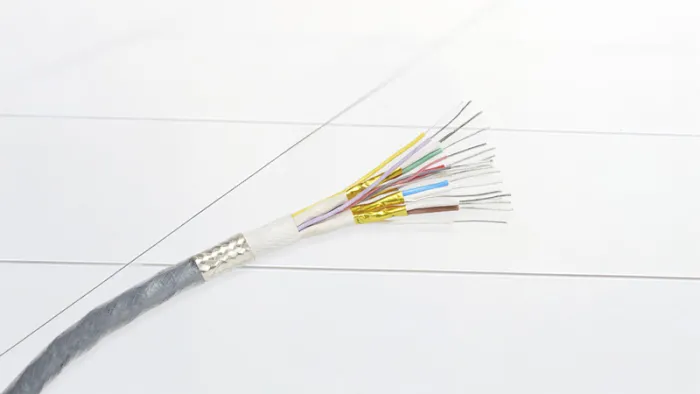

These values demonstrate the electrical, mechanical and environmental performance of GORE® HDMI Cables, 2.0 version packaged with GORE Abrasion Resistant Cable Jacket.

| Elec./Mech./Environ. Property | Value |

|---|---|

| Signal Transmission Speed Gb/s | Up to 18 |

| Standard Impedance Ohms | 100 ± 10 |

| Typical Operating Voltage V | < 15 |

| Nominal Velocity of Propagation % | 80 |

| Nominal Time Delay ns/m (ns/ft.) | 4.10 (1.25) |

| Capacitance pF/m (pF/ft.) | 230.0 (70.0) |

| Maximum Skew Within Pair ps/m (ps/ft.) | 15.0 (4.6) |

| Dielectric Withstanding Voltage Vrms Conductor-to-Conductor Conductor-to-Shield | 1500 1000 |

| Jacket Material | Engineered Fluoropolymer Fiber Braid |

| Jacket Color | Black |

| Conductor | Silver-Plated Copper Alloy |

| Conductor Color Coding | High-Speed Pairs: Blue/White, Brown/White, Green/White, Red/White Singles: Orange, Violet, White, Yellow Triad: Gray, Pink, Tan |

| Dielectric Material | Expanded PTFE/PTFE |

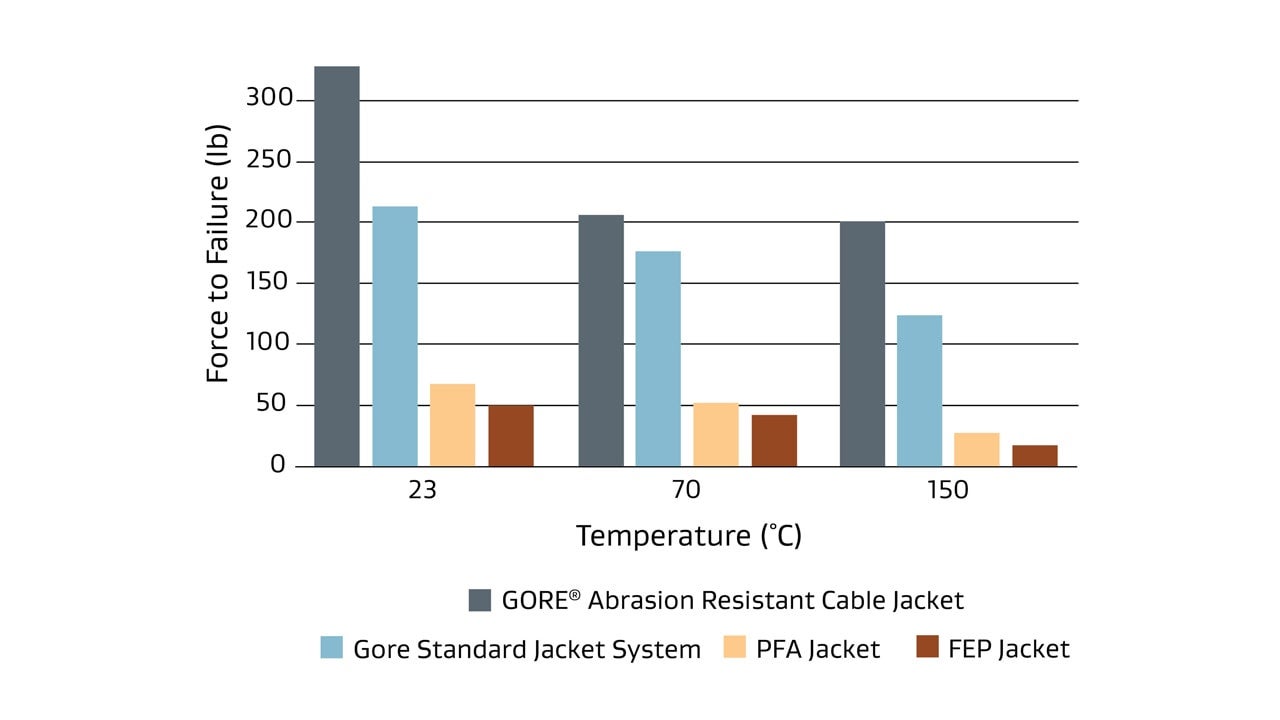

| Cut-Through Resistance kg (lb) (SAE AS4373™-703) 23°C 70°C 150°C | 122 (270) 73 (160) 59 (130) |

| Scrape Abrasion Resistance Cycles (EN3475-503) 30°C & 55°C / F = 1.2 daN | > 8,000 |

| Temperature Range °C | -65 to +200 |

GORE Abrasion Resistant Cable Jacket complies with the most current aerospace and defense standards and requirements, including:

- ABD0031 (AITM 2.0005); BSS7230; FAR Part 25, Appendix F, Part I: Flammability

- ABD0031 (AITM 3.0005); BSS7239: Toxicity

- ABD0031 (AITM 3.0008B); BSS7238; FAR Part 25, Appendix F, Part V: Smoke Density

- SAE AS4373™: Test Methods for Insulated Electric Wire (Contact Gore for available data)

The 2.0 version of GORE HDMI Cables packaged with GORE Abrasion Resistant Cable Jacket is available in a standard size.

RCN9195

Featured Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 455 4684

Have questions or unique requirements?

Our experts are here to guide you.