Semiconductor

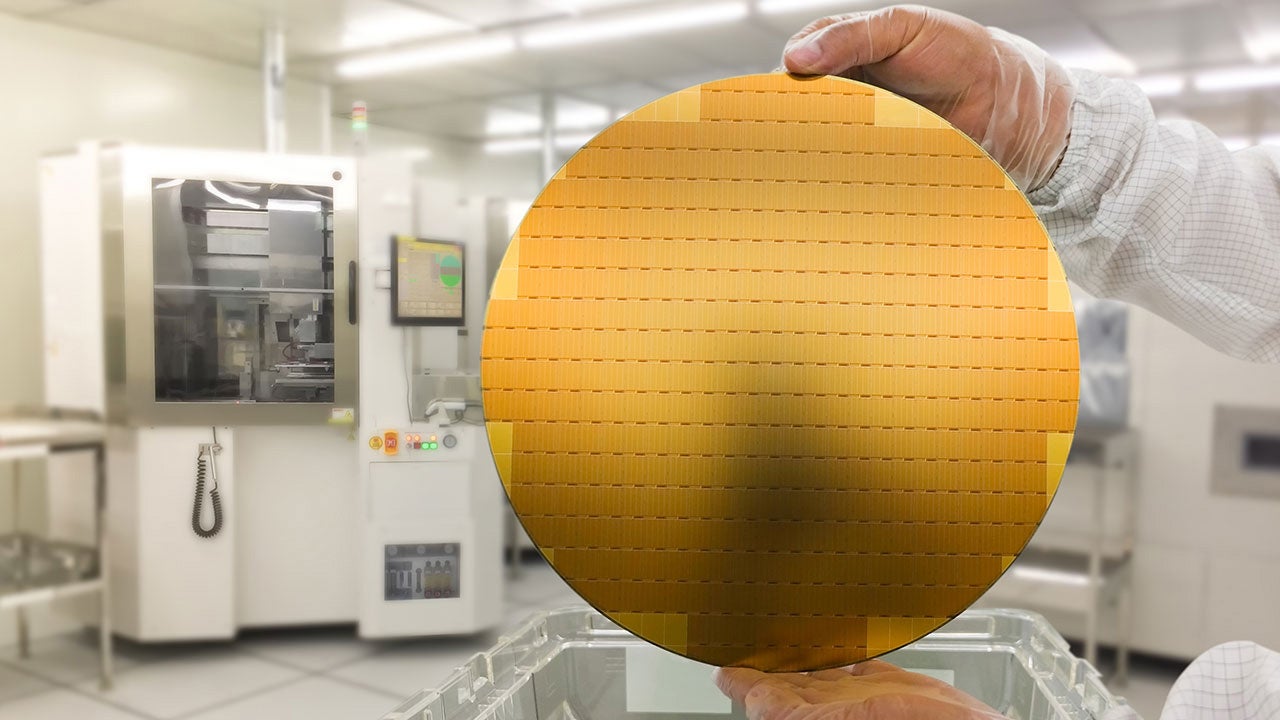

Gore’s advanced technologies offer improvements throughout semiconductor manufacturing processes that ensure cleanliness, durability, flexibility and reliability.

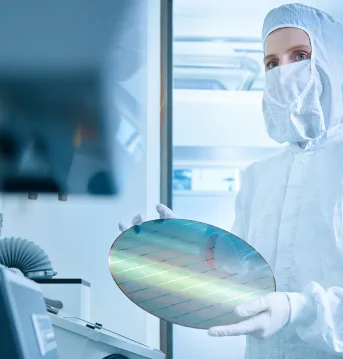

Driving Innovation in Front-End Wafer Processing and Back-End Assembly and Testing

Gore continually explores new technologies, solutions and partnerships with like-minded manufacturers to push the boundaries of advancement.

The semiconductor industry continues to demand smaller microchips with more processing power and memory, higher purity fab processes, increased wafer output and improved yields — all while reducing production costs.

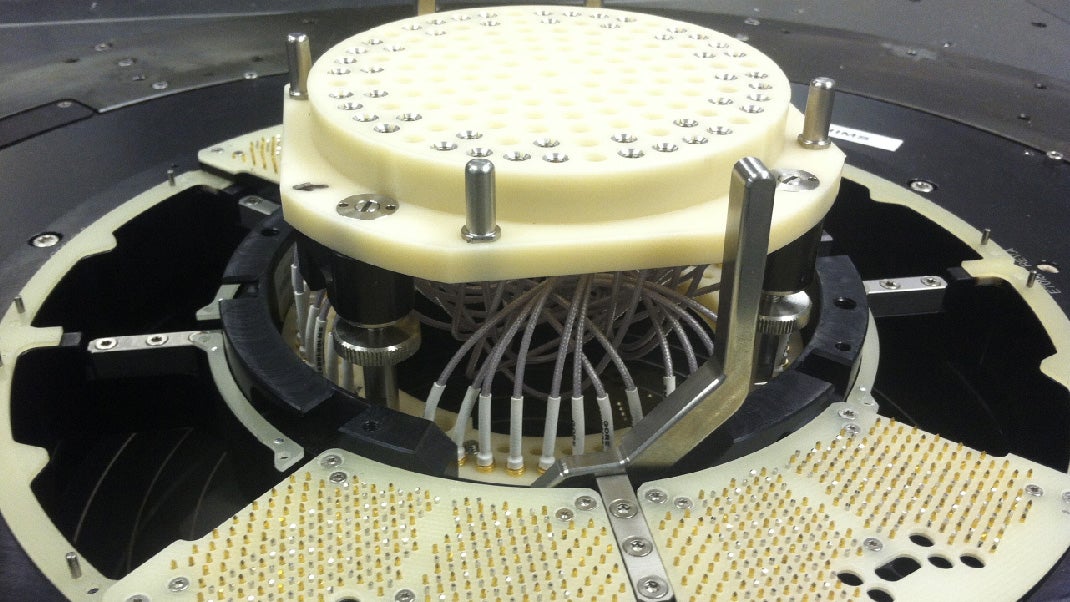

Advanced solutions from Gore enhance semiconductor manufacturing with chemically inert PTFE-based materials that withstand the harshest cleanroom conditions. From front-end wafer production to back-end assembly and testing, our cables, assemblies, membranes and modules ensure clean, reliable and repeatable processes.

High-Precision Lithography Solutions for Semiconductor Manufacturing Excellence

Gore empowers next-gen semiconductor manufacturing with advanced lithography solutions for precision, efficiency and scalability.