Automotive / Electrified Vehicles

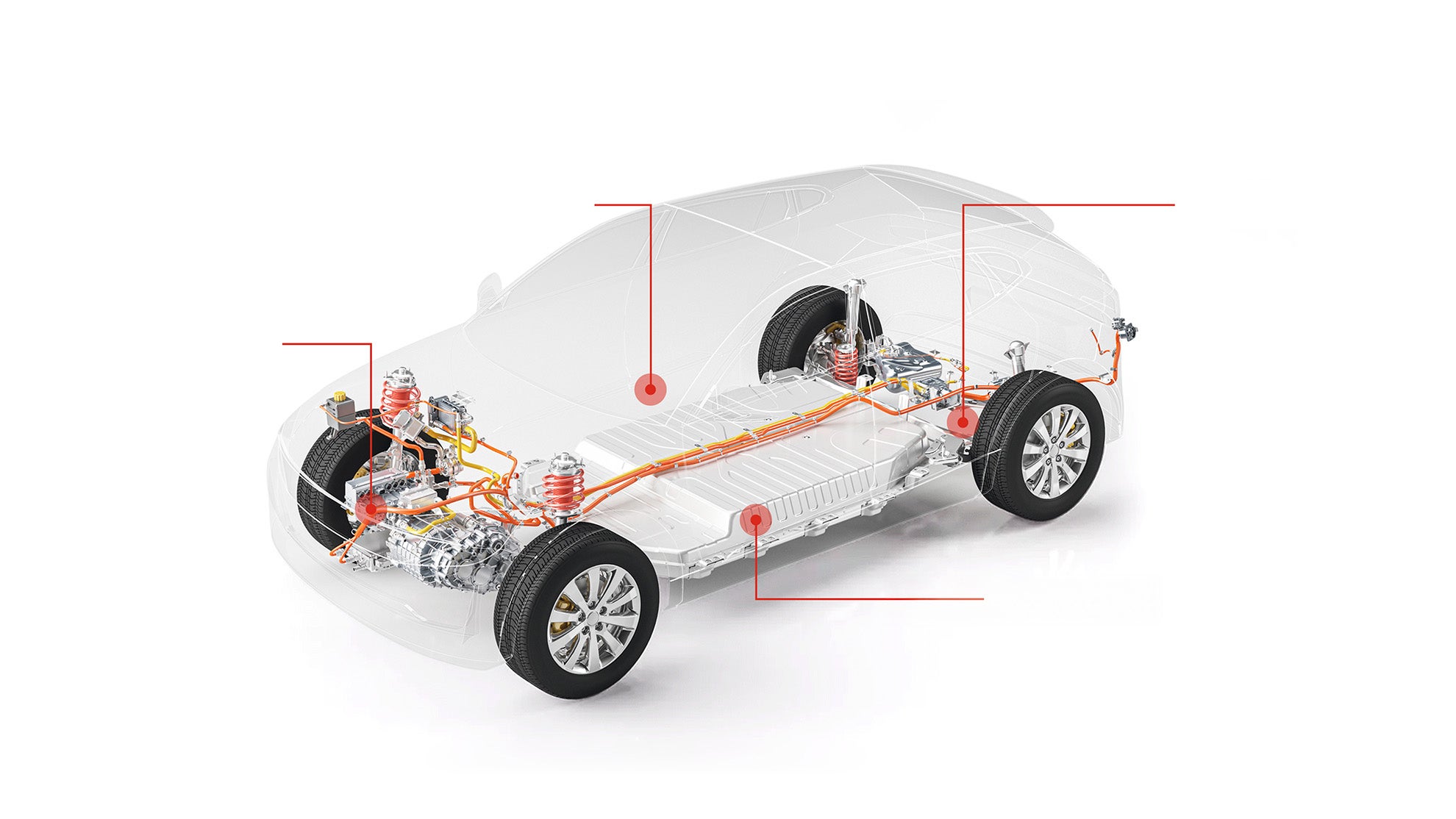

Gore supports OEMs and Tier suppliers in the electric vehicle industry with innovative venting solutions for electronic components, supporting sustainability, decarbonization, and the global "Net Zero by 2050" roadmap.

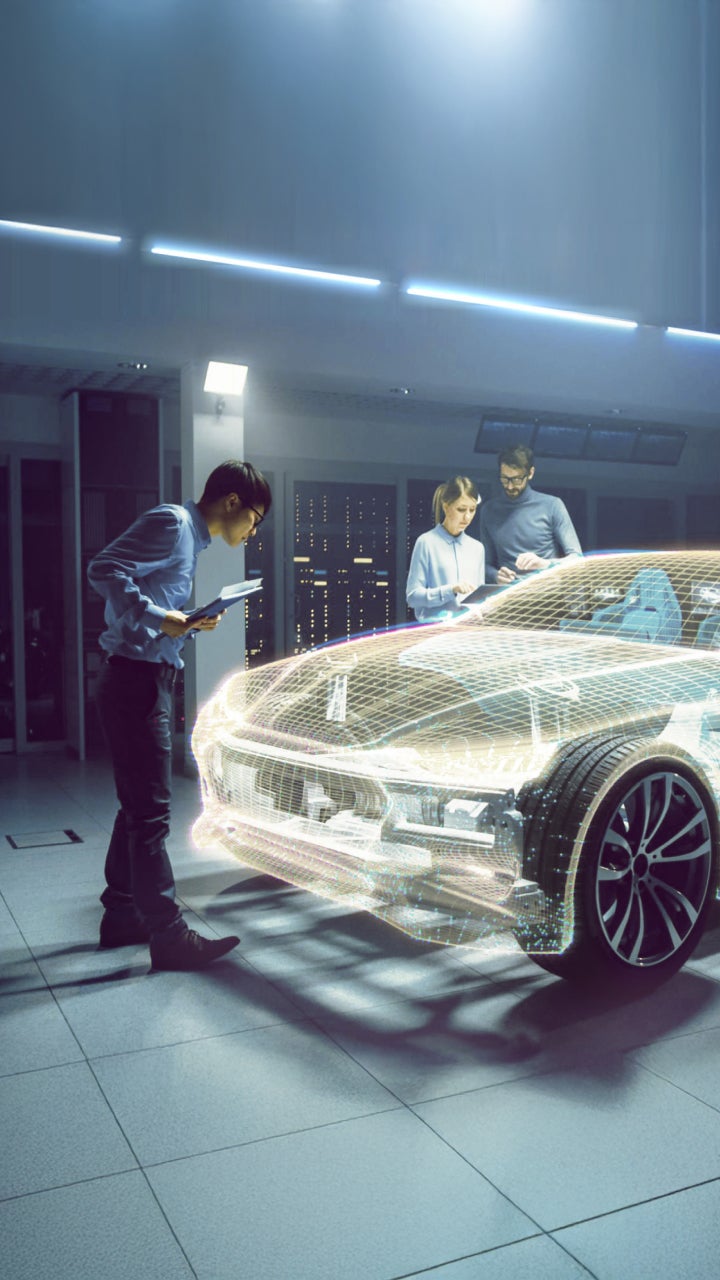

Empowering the Future of Mobility with Sustainable Automotive Solutions

At Gore, we’re driving innovation forward with sustainable membrane solutions that enhance the performance and protection of Automotive and EV components. As the industry accelerates the shift to reduce CO₂ emissions, we remain committed to providing advanced technologies that help manufacturers build more efficient, reliable, and environmentally responsible vehicles.

Our experts collaborate closely with customers, developing cutting-edge solutions for moisture, thermal, and acoustic management while optimizing battery performance in EVs. By continuously exploring new technologies, we address industry challenges and create solutions for unmet needs—paving the way for the future of mobility.