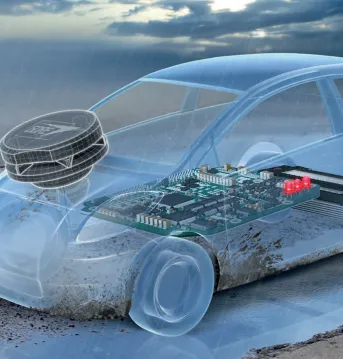

GORE® Automotive Vents for Electronics

Our venting technology equalizes pressures while blocking fluids and contaminants that could damage sensitive electronics or degrade component reliability.

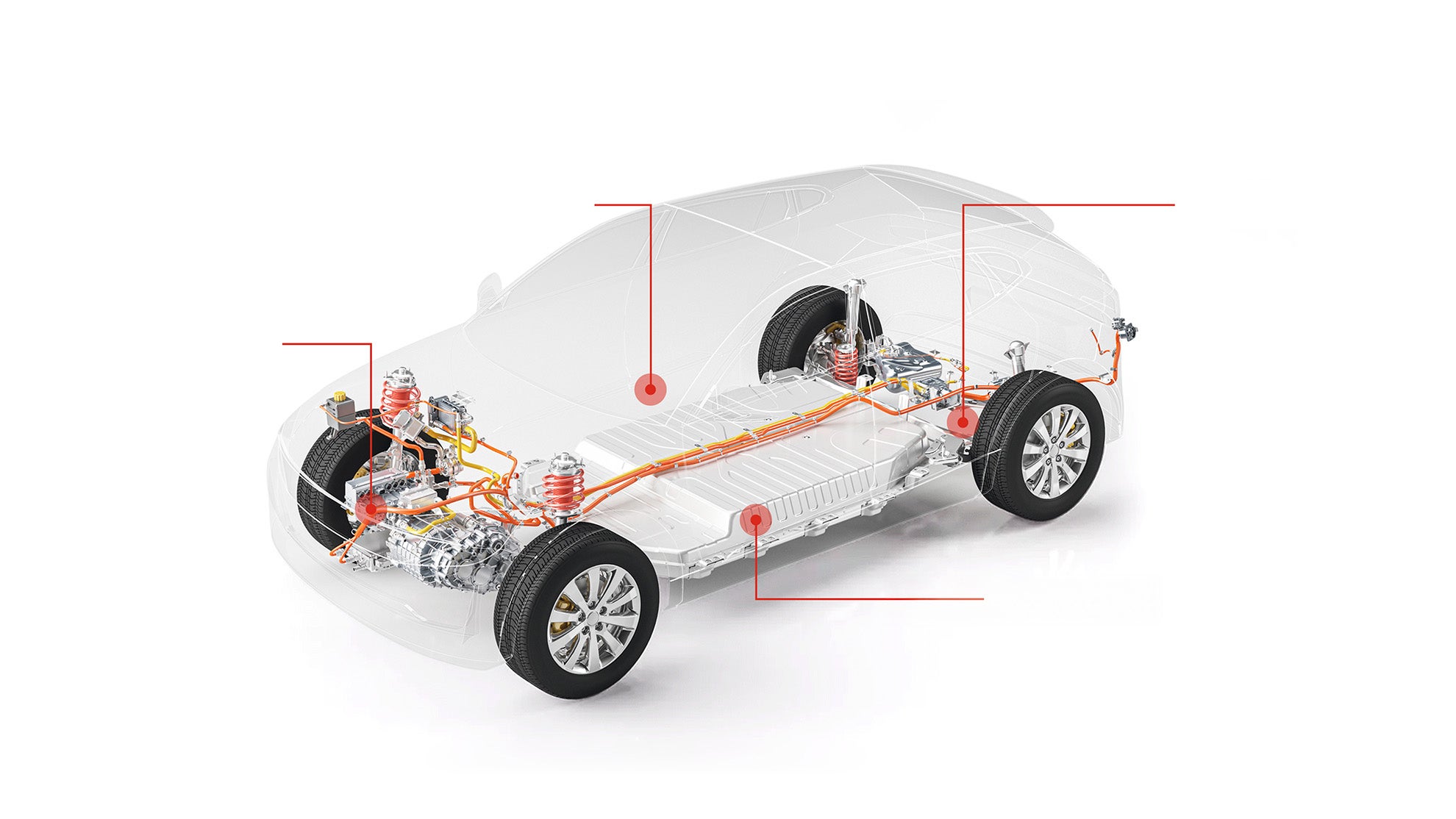

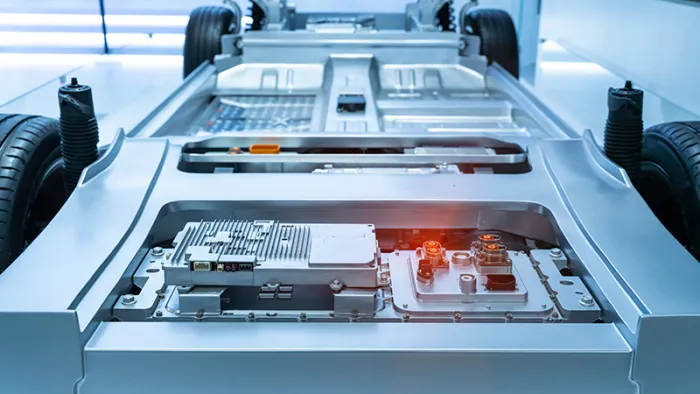

Reliable Auto Venting Solutions for Water-proofing EV & ICE Electronics

Gore‘s auto venting products block ingress of rain, sleet, snow, dust, dirt and debris, protecting electronic components in extreme environments. They continuously respond to pressure differentials, quickly equalizing over-pressures and vacuums, which protects the integrity and longevity of seals for life-of-vehicle performance.

Technical Specifications

Screw-In Vents and Snap-Fit Vents:

Mechanically rugged and easy to integrate.

Screw-In Vents

- Standard Series: Withstands typical automotive fluids and continuous temperatures up to 125°C.

- High-Airflow Series: Has 8x the typical airflow of our Standard Series, for very large components/electric motors/batteries for hybrids.

Snap-Fit Vents

- Standard Series: Withstands typical automotive fluids and continuous temperatures up to 125°C.

- High Temperature Series: For long-lasting resistance to chemicals and mineral oils even after extended exposure to temperatures up to 150°C.

- High Airflow Series: Has 5x the typical airflow of our Standard Series, for very large components, electric motors, or for EV/Hybrid battery box venting.

- Compact Series: Robust protection in a low profile design, for extremely small components. Scannable Digital Matrix Code (DMC) for 100% airflow check and enhanced traceability.

| Screw-In Vents | Snap-Fit Vents | |

|---|---|---|

| Installation | Can be removed for component maintenance | Secure, permanent installation Chamfered through-hole |

| Ratings | UL94 V-0 rated housing and o-ring IPx9k rating – no protective wall needed | UL94 HB rated housing and o-ring IPx9k rating with a protective wall |

| Thickness | For 3.0 mm housing walls with a counter nut, or 5.0 mm walls without a counter nut | For 3.5-4.0 mm thick housing walls |

Small, lightweight vents install easily, bond securely and have high chemical roll-off performance, to maintain airflow.

- High Durability Series: These all-membrane vents provide our highest level of protection and durability in the harshest conditions. Designed to perform reliably in either outside-mount or inside-mount applications. A range of sizes, for small to medium enclosures.

- High-Airflow Series: These laminate vents provide our highest airflow, for faster pressure equalization. Designed for inside mounting only. A choice of sizes, for small to medium enclosures.

Save space, install easily and securely, and provide lasting protection for sensitive electronics.

- High Airflow Series: Uses a multi-layer laminate construction to deliver our highest airflow and good chemical resistance. For use in typical operating temperatures from -40 °C to 150 °C. Available as cut disks in bags.

- High Temperature Series: Offers our highest temperature- and chemical-resistance, in our thinnest format. The 100% ePTFE construction withstands operating temperatures from -40 °C to 160 °C. Available as cut disks on rolls.

Technical Information

We commit to every customer that “our products will do what we say they will do" — and we stand behind that promise with our worldwide resources, expertise, and quality processes.

Added Electric Vehicle Protection That Goes Beyond the Standard

Gore goes beyond compliance to ensure dependable performance of our automotive vents in high-voltage applications. With rigorous safety oversight, stringent testing and enhanced warranty measures, Gore safeguards your critical electronic systems.

Product Safety Confirmative Representative (PSCR)

Our dedicated representative will ensure each product meets and exceeds applicable safety requirements before release and answer customer inquiries.

Automated Testing

To ensure consistent quality, Gore employs automated testing on every vent to ensure reliable, human-error-free testing processes and improved statistical process control.

To learn more about our quality assurance improvements, contact a Gore EV Specialist.

Gore monitors and strives to comply with all regulations applicable to our products.

We have worked with our suppliers to eliminate PFOA from our supply chain. Our products meet EU REACH regulations EU 1907/2006 and EU 2019/2021.

Screw-In vents for manual, semi-automated and automated installation

| Product Name Order number for samples | Product Number Order number for series production |

|---|---|

| PolyVent Standard | |

| AVS 1190 | AMF301190 |

| PolyVent High Airflow | |

| AVS 1191 | AMF301191 |

Snap-fit vents for manual, semi-automated and automated installation

| Product Name Order number for samples | Product Number Order number for series production |

|---|---|

| PolyVent Standard | |

| AVS 14 | AMF300114 |

| PolyVent High Temperature | |

| AVS 67 | AMF300167 |

| PolyVent High Airflow | |

| AVS 70 | AMF300070 |

| PolyVent Compact | |

| AVS 200 | AMF300200 |

Adhesive vents for automated installation

| Product Name Order number for samples | Product Number Order number for series production |

|---|---|

| High Durability Series (Outside or inside mount) | |

| AVS 247S | AVE230206 |

| AVS 248S | AVE230408 |

| AVS 245S | AVE230610 |

| AVS 251S | AVE230814 |

| AVS 255S | AVE230919 |

| High Airflow Series (Inside mount) | |

| AVS 2525 | AVE930307 |

| AVS 2545 | AVE930610 |

Weldable vents for ultrasonic and thermal processes

| Product Name (order number for samples) | Product Number (order number for series production) |

|---|---|

| High Airflow Series | |

| AVS 305 | AMP300248-00057 |

| AVS 308 | AMP300249-00080 |

| AVS 310 | AMP300250-00100 |

| AVS 311 | AMP300251-00117 |

| AVS 314 | AMP300252-00140 |

| High Temperature Series | |

| AVS 26 | AMP200024-00060 |

| AVS 108 | AMP200082-00080 |

| AVS 39 | AMP200069-00100 |

| AVS 28 | AMP200055-00120 |

| AVS 29 | AMP200023-00140 |

Featured Content

Related Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 356 4622

Have questions or unique requirements?

Our experts are here to guide you.