GORE® Automotive Vents for Exterior Lighting

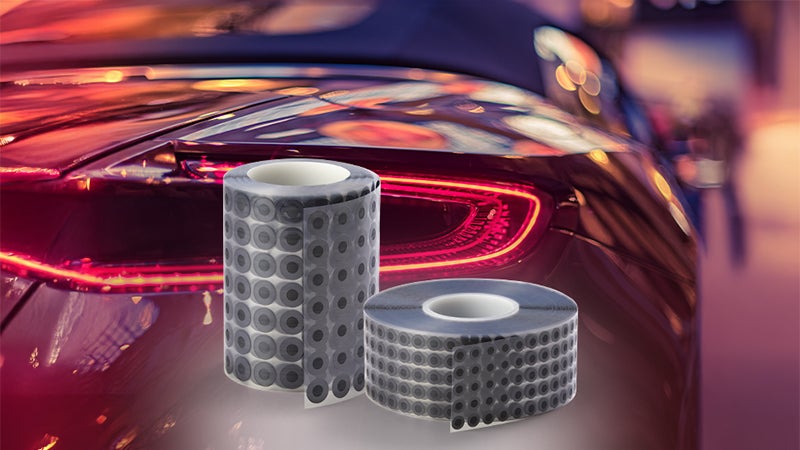

Our automotive adhesive vents offer life-of-vehicle condensation reduction, pressure equalization and ingress protection for headlamp, rear lamp, fog lamp and accessory lamp assemblies.

Reliable Protection for Lamp Assemblies

Gore’s all-membrane automotive lighting vents enhance component reliability and longevity by providing life-of-vehicle condensation reduction, pressure equalization, and protection against entry of water, automotive fluids, fine dust and dirt. Our adhesive vents bond firmly and perform reliably in the most challenging environments.

GORE Vents: Condensation Management

Learn how GORE Vents can help your headlamps excel at managing condensation.

Condensation Causes and Cures in BEV Headlamps

See which solution proved most effective.

Technical Information

Gore monitors and strives to comply with all regulations applicable to our products.

We have worked with our suppliers to eliminate PFOA from our supply chain. Our products meet EU REACH regulations EU 1907/2006 and EU 2019/2021.

PPAP: An Overview

For Level 1, 2, 3 or 4 submissions, or waivers, our documentation is complete and concise to streamline your participation in this process.

What Quality Means, to Us and for You

We commit to every customer that “our products will do what we say they will do" — and we stand behind that promise with our worldwide resources, expertise, and quality processes.

IATF16949:2016

This International Automotive Task Force (IATF) standard defines quality system requirements for use in the automotive supply chain. It’s based on ISO 9001:2015, as well as OEM customer-specific requirements.

Adhesive vents for manual, semi-automated and automated installation

| Product Name Order number for samples | Product Number Order number for series production | |

|---|---|---|

| Multi-up configuration | One-up configuration | |

| Headlamps | ||

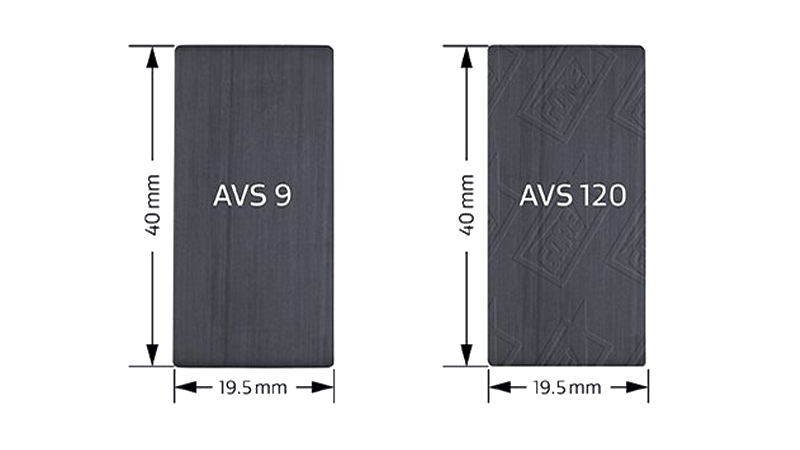

| AVS 120 | VE2122 | VE2123 |

| AVS 9 | VE0020GMC | VE2068 |

| AVS 113 | VE2113 | VE2114 |

| AVS 100 | VE2084 | VE2086 |

| Rear Lamps | ||

| AVS 2 | VE0001VAP | VE2051 |

| AVS 5 | VE2004 | VE2016 |

| AVS 600 | VE2100 | ------ |

| AVS 610 | ------ | VE2110 |

| AVS 601 | VE2101 | ------ |

| AVS 611 | ------ | VE2111 |

| AVS 602 | VE2102 | ------ |

| AVS 612 | ------ | VE2112 |

| Accessory and Fog Lamps | ||

| AVS 2 | VE0001VAP | VE2051 |

| AVS 5 | VE2004 | VE2016 |

| AVS 118 | VE2117 | VE2118 |

| AVS 119 | VE2119 | VE2120 |

| Manual installation | Automated installation |

|---|---|---|

AVS 22 | VE2094 | VE2095 |

AVS 23 | VE2096 | VE2097 |

Call us: +1 800 346 7391 for info on: AVS 43, AVS 15/AVS 16; AVS 17/AVS 18; AVS 4/AVS 7. If your product number isn’t listed above, please contact us.

Featured Content

Related Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 356 4622

Have questions or unique requirements?

Our experts are here to guide you.