GORE® Cable Protection Systems

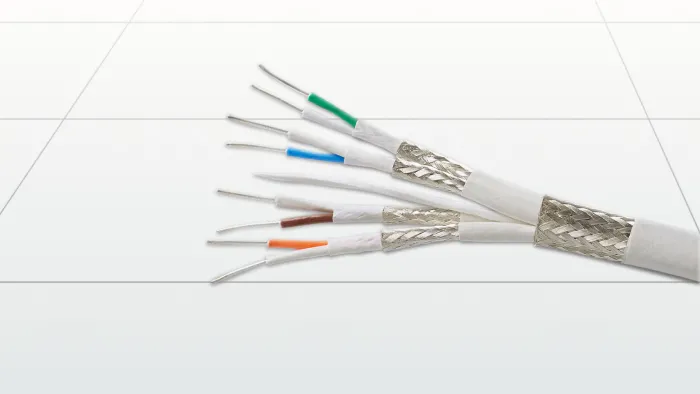

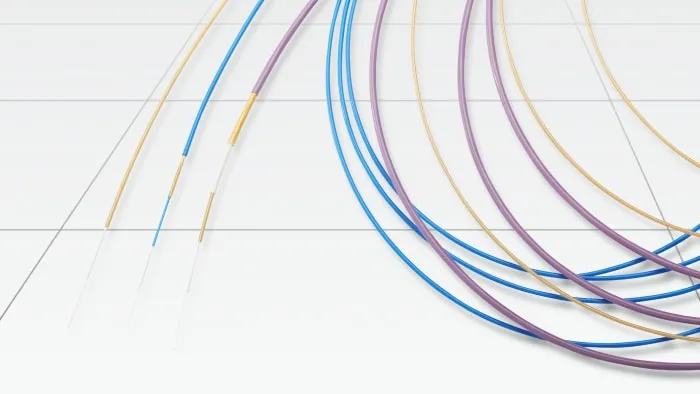

Our extremely durable jackets provide the highest protection against crushing and abrasion, preventing damage to fiber optics and copper wires during installation and operation.

Durable Jackets Against Harsh Routing & Operational Conditions

GORE® Cable Protection Systems withstand complex routing, constant vibration, corrosive chemicals, harsh fluids and oils, extreme temperatures and other environmental factors. These cable jackets also contribute to valuable weight savings in aircraft and defense vehicles.

Technical Information

These values demonstrate the mechanical and environmental performance of GORE Cable Protection Systems for defense aircraft and vehicles, along with civil aircraft.

| Mechanical / Environmental Property | Value |

|---|---|

| Jacket Material | Expanded PTFE/PTFE |

| Jacket Color | Black with Violet Stripes |

| Temperature Range °C | -65 to +260 |

Complete a short form for instant access to selected drawings with technical specifications from W. L. Gore & Associates.

GORE Cable Protection Systems have been rigorously tested and qualified to comply with the following aerospace and defense specifications, including:

- ABD0031 (AITM 2.0005); BSS7230; FAR Part 25, Appendix F, Part I: Flammability

- ABD0031 (AITM 3.0005); BSS7239: Toxicity

- ABD0031 (AITM 3.0008B); BSS7238; FAR Part 25, Appendix F, Part V: Smoke Density

- SAE AS81914™/1-6: Plastic Convoluted Tubing Requirements

| Gore Part Number | Overall Size mm (in) | Minimum Convoluted Tubing ID mm (in) | Maximum Convoluted Tubing OD mm (in) |

|---|---|---|---|

| FON1594 | 7.2 (0.29) | 3.2 (0.13) | 3.9 (0.15) |

| FON1580 | 9.4 (0.37) | 4.6 (0.18) | 8.1 (0.32) |

| FON1611 | 13.5 (0.53) | 7.8 (0.31) | 11.4 (0.45) |

| FON1612 | 17.1 (0.68) | 10.8 (0.43) | 15.0 (0.59) |

| FON1599 | 17.9 (0.71) | 12.4 (0.49) | 16.8 (0.66) |

Featured Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 455 4684

Have questions or unique requirements?

Our experts are here to guide you.