GORE® DVI Cables (Digital Only) for Aerospace & Defense

Our single-link cables reliably support the highest video resolution on displays for optimal viewing in demanding air and defense radar environments.

Optimal Viewing on High-Definition Displays

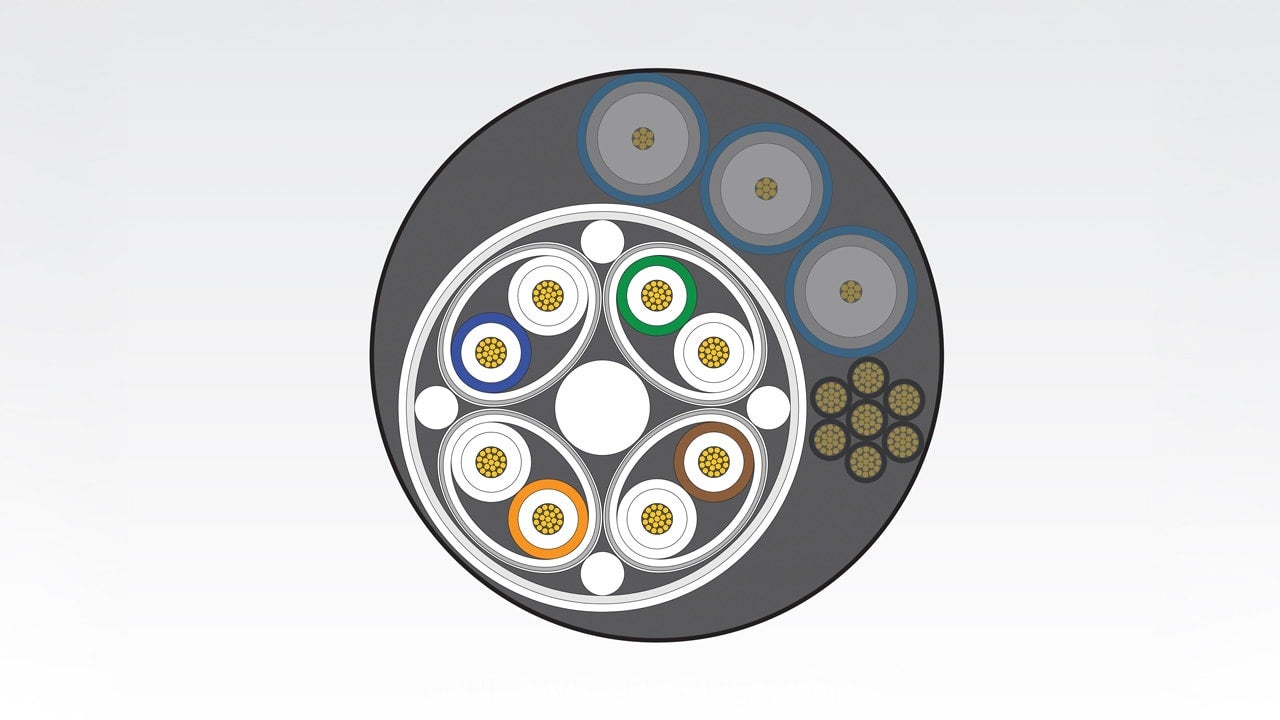

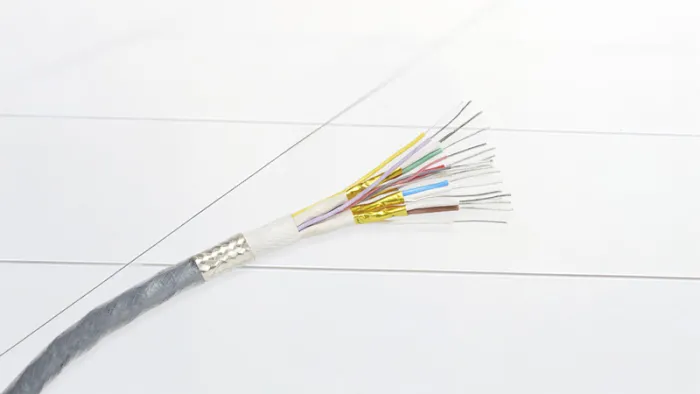

GORE® DVI Cables (Digital Only) deliver exceptional signal quality and high data rate video transmission in demanding EMI environments. They meet stringent military and aerospace standards for impedance control, insertion loss, skew and EMI shielding while fitting easily into a harness cross-section with other components.

Is High-Speed Data Transmission in Defense Aircraft a System Lifetime or Costly Afterthought?

Watch this free on-demand webinar on this topic and listen to Gore experts share their deep industry knowledge and materials expertise while using real-world examples.

GORE® High Speed Data Cables for Aerospace & Defense

Combining dielectric expertise with innovative fluoropolymer materials, we bring a portfolio of standard high data rate cables with proven performance over leading alternatives.

Technical Information

These values demonstrate the electrical, mechanical and environmental performance of GORE DVI Cables (Digital Only) for aerospace and defense.

| Elec./Mech./Environ. Property | Value |

|---|---|

| Standard Impedance Ohms | 100 ± 10 |

| Typical Operating Voltage V | < 15 |

| Nominal Velocity of Propagation % | 80 |

| Nominal Time Delay ns/m (ns/ft.) | 4.07 (1.24) |

| Capacitance pF/m (pF/ft.) | 40.0 (12.0) |

| Maximum Skew ps/m (ps/ft.) Pair-to-Pair Within Pair | 52.50 (16.0) 13.12 (4.0) |

| Dielectric Withstanding Voltage Vrms Conductor-to-Conductor Conductor-to-Shield | 1500 1000 |

| Jacket Material | Engineered Fluoropolymer |

| Jacket Color | White (Laser Markable) |

| Conductor | Sliver-Plated Copper Alloy |

| Conductor Color-Coding | Blue/White, Brown/White, Green/White, Orange/White |

| Dielectric Material | Expanded PTFE/PTFE |

| Temperature Range °C | -65 to +200 |

Complete the short form below for instant access to a drawing with technical specifications from W. L. Gore & Associates.

Meticulously tested and pre-qualified, GORE DVI Cables (Digital Only) meet stringent aerospace and defense standards, including:

- ABD0031 (AITM 2.0005); BSS7230; FAR Part 25, Appendix F, Part I: Flammability

- ABD0031 (AITM 3.0005); BSS7239: Toxicity

- ABD0031 (AITM 3.0008B); BSS7238; FAR Part 25, Appendix F, Part V: Smoke Density

- ANSI/NEMA WC 27500: Environmental Testing, Jacket and Marking

- SAE AS4373™: Test Methods for Insulated Electric Wire (Contact Gore for available data)

GORE DVI Cables (Digital Only) for aerospace and defense are available in a standard size 24 AWG.

GSC-01-85249-24S

Featured Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 455 4684

Have questions or unique requirements?

Our experts are here to guide you.