GORE® FireWire® Cables for Aerospace & Defense

Our copper-based cables reliably carry high-fidelity signals, transfer high-speed data and video signals, endure continuous flexing, provide superb protection and save weight on aircraft.

Smaller Cables Save Weight & Are Durable in Extreme Conditions

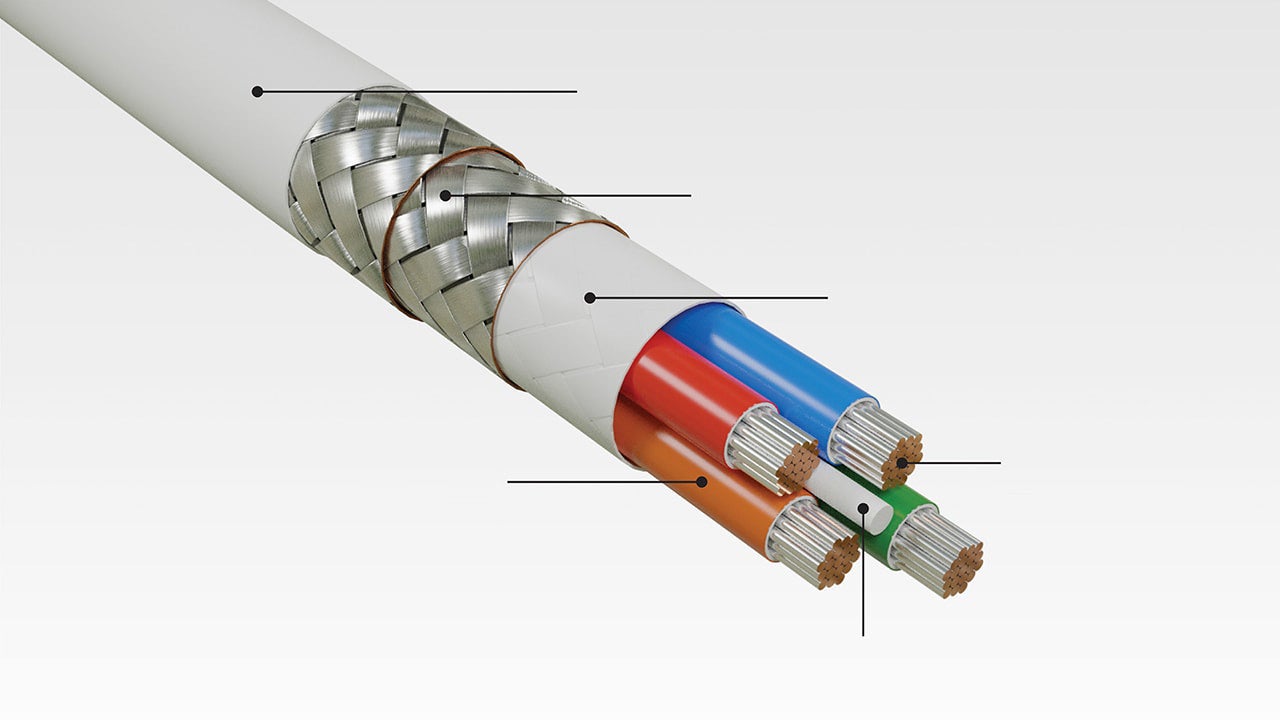

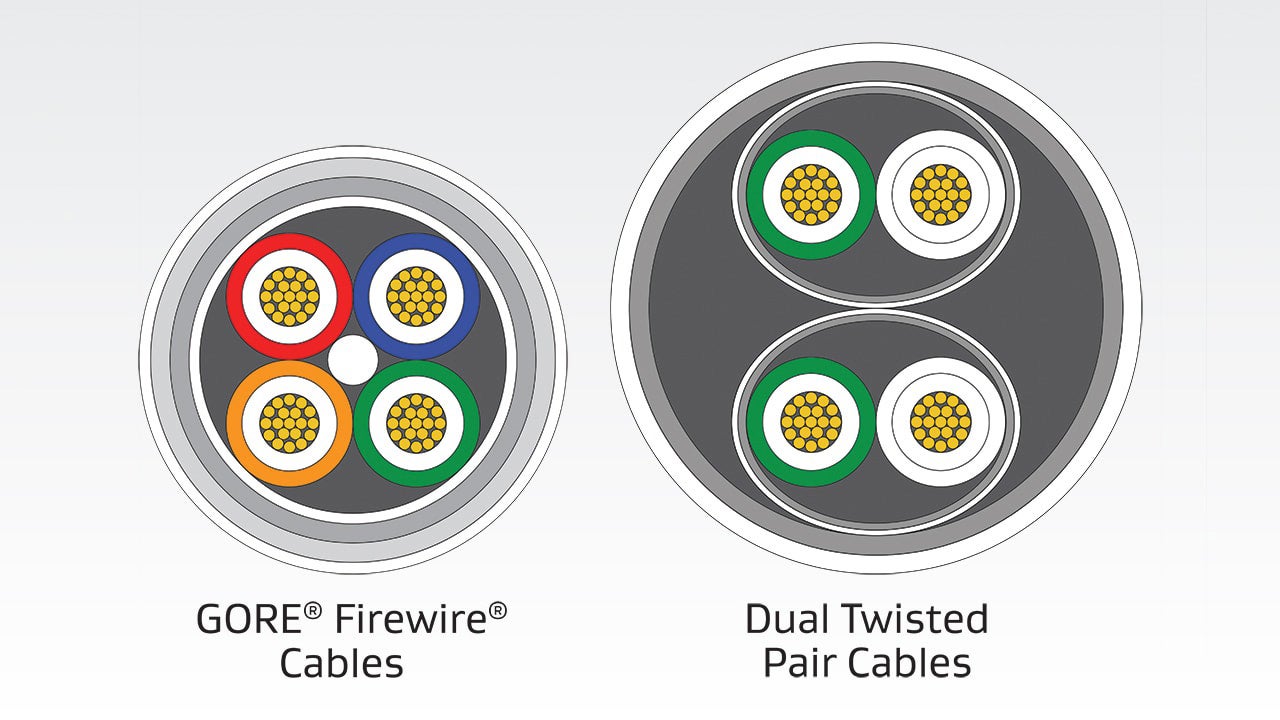

GORE® FireWire® Cables transmit uninterrupted S400 data rate signals with flexure at lengths up to 30 m (100 ft.) in all aircraft conditions. Our quadrax design is smaller and lighter than dual twisted pair constructions, saving weight while providing a protective barrier against tough flight and maintenance conditions.

Is High-Speed Data Transmission in Defense Aircraft a System Lifetime or Costly Afterthought?

Watch this free on-demand webinar on this topic and listen to Gore experts share their deep industry knowledge and materials expertise while using real-world examples.

GORE® High Speed Data Cables for Aerospace & Defense

Combining dielectric expertise with innovative fluoropolymer materials, we bring a portfolio of standard high data rate cables with proven performance over leading alternatives.

Technical Information

These values demonstrate the electrical, mechanical and environmental performance of GORE FireWire for military and civilian aircraft.

| Elec./Mech./Environ. Property | Value |

|---|---|

| Signal Transmission Speed Mb/s | Up to 400 |

| Standard Impedance Ohms | 110 +6/-4 |

| Typical Operating Voltage V | < 15 |

| Nominal Velocity of Propagation % | 80 |

| Nominal Time Delay ns/m (ns/ft.) | 4.10 (1.25) |

| Capacitance pF/m (pF/ft.) | 36.1 (11.0) |

| Typical Skew Within Pair ps/m (ps/ft.) | 3.5 (1.1) |

| Dielectric Withstanding Voltage Vrms Conductor-to-Conductor Conductor-to-Shield | 1500 1000 |

| Jacket Material | Engineered Fluoropolymer |

| Jacket Color | White (Laser Markable) |

| Conductor | Silver-Plated Copper or SPC Alloy |

| Conductor Color-Coding | Blue/Orange, Green/Red |

| Dielectric Material | Expanded PTFE/PTFE |

| Temperature Range °C | -55 to +200 |

Complete the short form below for instant access to selected drawings with technical specifications from W. L. Gore & Associates.

Methodically tested and pre-qualified, GORE FireWire Cables comply with rigorous standards and requirements for aerospace and defense, including:

- ABD0031 (AITM 2.0005); BSS7230; FAR Part 25, Appendix F, Part: Flammability

- ABD0031 (AITM 3.0005); BSS7239: Toxicity

- ABD0031 (AITM 3.0008B); BSS7238; FAR Part 25, Appendix F, Part V: Smoke Density

- ANSI/NEMA WC 27500: Environmental Testing, Jacket and Marking

- SAE AS4373™: Test Methods for Insulated Electric Wire (Contact Gore for available data)

- SAE AS5643™: IEEE-1394b Interface Requirements for Military and Aerospace Vehicle Applications

- SAE AS5643™/2: S200 Copper Media Interface Characteristics Over Extended Distances

- SAE AS5643™/3: IEEE-1394 Beta PHY Enhancements

- SAE AS5657A™: Test Plan/Procedure for AS5643 IEEE-1394b Interface Requirements for Military and Aerospace Vehicle Applications (Contact Gore for available data)

GORE FireWire Cables for avionics are available in standard sizes.

RCN8645 (22 AWG)

RCN8647 (24 AWG)

RCB8652 (26 AWG)

Gore’s part numbers below are fully compliant with JSFY18 aircraft requirements.

RCN9206 (22 AWG)

RCN9205 (24 AWG)

RCN9204 (26 AWG)

Featured Content

Explore More

FireWire is a trademark of Apple, Inc., registered in the U.S. and other countries.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 455 4684

Have questions or unique requirements?

Our experts are here to guide you.