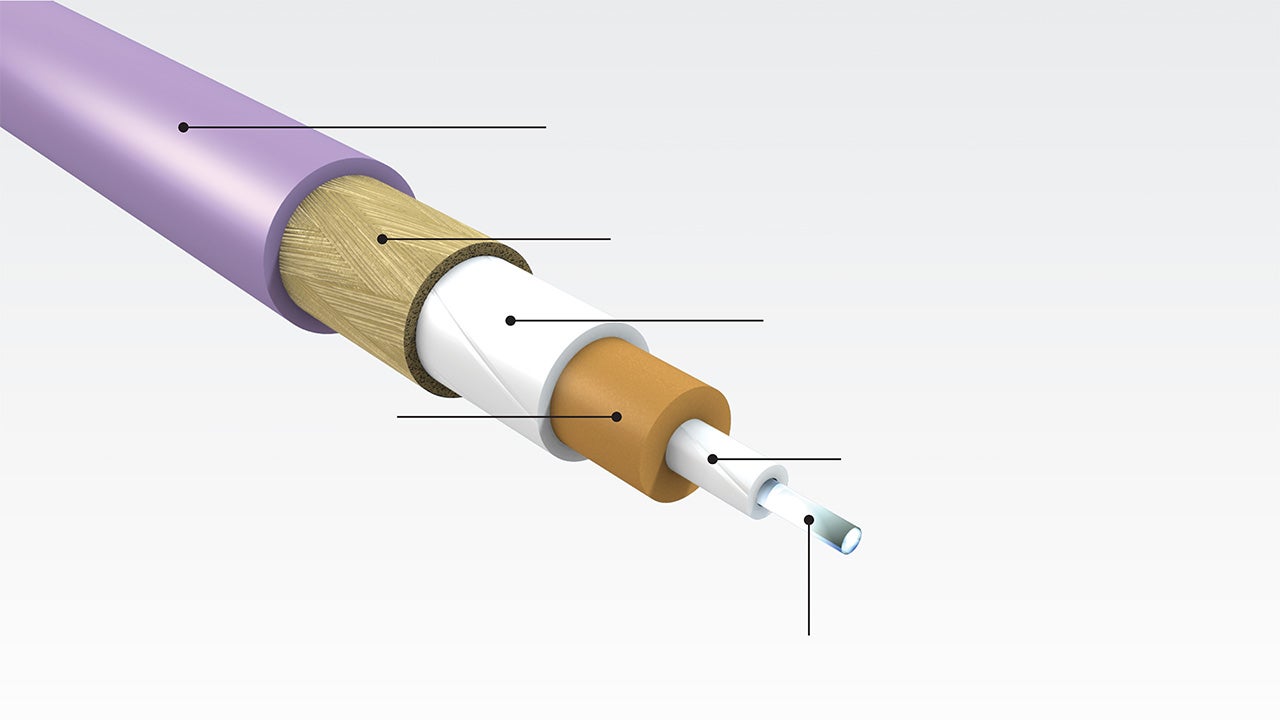

GORE® Fiber Optic Cables for Aerospace & Defense

Higher bandwidth optical fibers in robust, space-saving constructions for next-gen systems, transmitting instant data and video at maximum capacity.

Higher Bandwidth Signals, Proven Robust Construction

GORE® Fiber Optic Cables balance strength, small size, less weight and high flexibility compared to alternatives. They deliver reliable signals at high bandwidths while meeting or exceeding stringent industry standards for wide temperatures, durability and optical performance.

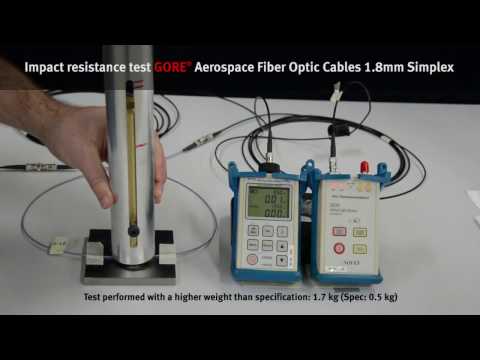

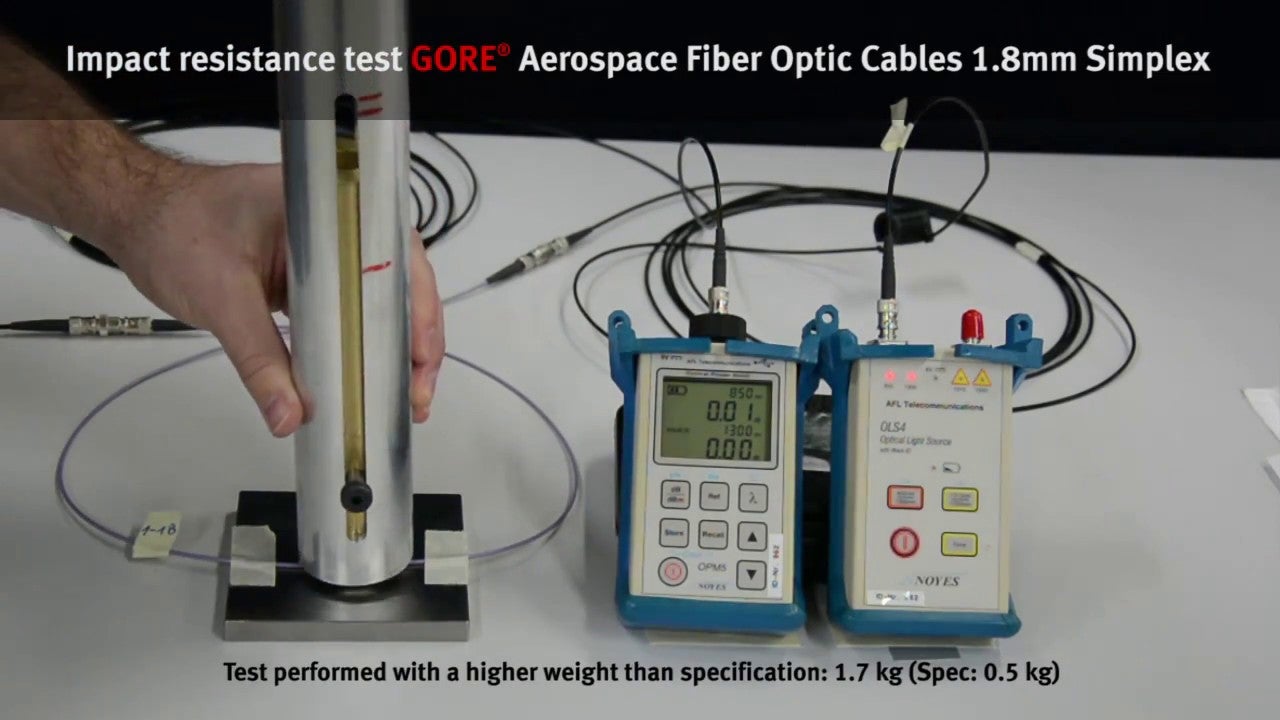

Impact Resistance Test

Gore tested the 1.8 mm Simplex according to ARINC 802-2 and BMS13-71 industry standards.

GORE® Fiber Optic Cables for Aerospace & Defense

Watch the video to see how our Simplex optical fibers meet current and future high data rate requirements for military aircraft and combat vehicles, as well as civilian aircraft.

Technical Information

These values demonstrate the optical, mechanical and environmental performance of GORE Fiber Optic Cables for aerospace and defense.

| Elec./Mech./ Environ. Property | 1.8 mm Simplex | 1.2 mm Simplexb | 0.9 mm Simplex (900 µm) |

|---|---|---|---|

| Signal Transmission Speed Gb/s | Up to 100 | Up to 100 | Up to 100 |

| Max Optical Loss dB/km 850 nm 1300 nm 1310 nm | 4.0 / ≤ 5.0a ≤ 3.0a 3.0 | — ≤ 1.5 — | 3.0 — 1.0 |

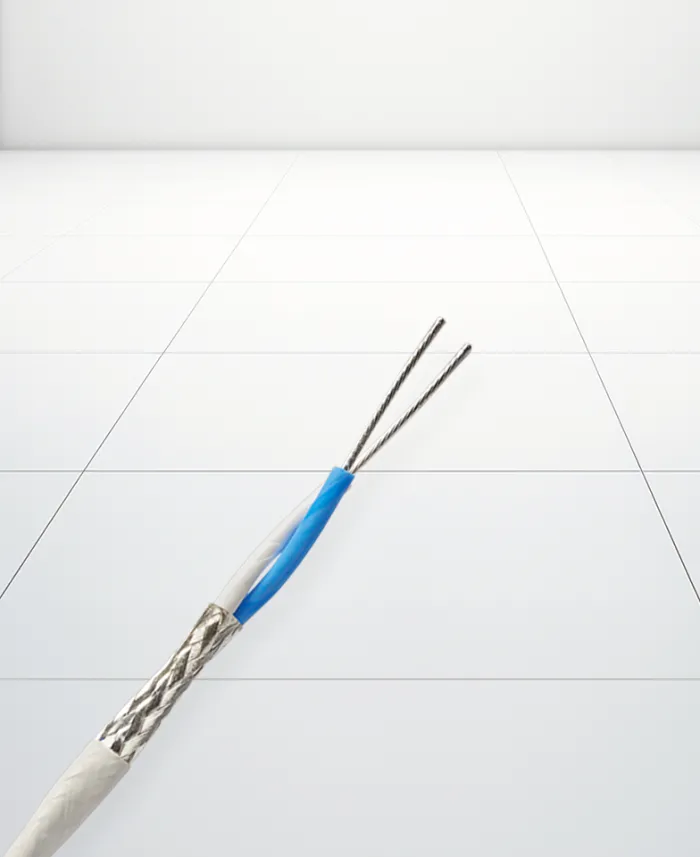

| Jacket Material | PFA | FEP | PEEK |

| Jacket Color | Violet or Yellow | Blue | Tan |

| Core Type | SM or Multi-Mode, Graded Index | SM or Multi-Mode, Graded Index | SM or Multi-Mode, Graded Index |

| Coating Type | High-Temperature Acrylate | ||

| Buffering System | Expanded PTFE/Crush-Resistant Layer OD: 900 µm (Nominal) | Expanded PTFE | Expanded PTFE/Crush-Resistant Layer OD: 900 µm (Nominal) |

| Temperature Range °C | -65 to +135 | -55 to +125c | -65 to +135 |

| Downloads | Data Sheet | Data Sheet | Data Sheet |

a. Based on Gore’s part numbers GSC-13-84943-07 and GSC-13-84943-17.

b. Based on Gore’s part number FON1307.

c. Other part numbers available with operating temperatures at +85°C and +200°C.

Complete the short form below for instant access to selected drawings with technical specifications from W. L. Gore & Associates.

Undergoing substantial qualification testing, GORE Fiber Optic Cables meet stringent industry standards and our customers’ requirements, including:

- ABD0031 (AITM 2.0005); BSS7230; FAR Part 25, Appendix F, Part I: Flammability

- ABD0031 (AITM 2.0005); BSS7230-F6; BSS7324-7.25; FAR Part 25, Appendix F, Part I: Flammability (FON1002, FON1003, FON1253, FON1307, FON1371)

- ABD0031 (AITM 3.0008B); BSS7238; FAR Part 25, Appendix F, Part V: Smoke Density

- ARINC 802-3; Performance Requirements (GSC-13-84639, GSC-13-84640, GSC-13-84943, GSC-13-85067-00)

- ABD0031 (AITM 3.0005); BSS7239: Toxicity

- EN3745-513; JN1177: Test Methods for Crush Resistance

- MIL-STD-202, Method 103: Humidity (FON1002, FON1003, FON1253, FON1307, FON1371)

- MIL-STD-810, Method 509: Salt Fog (FON1002, FON1003, FON1253, FON1307, FON1371)

- MIL-STD-810, Method 510: Sand and Dust (FON1002, FON1003, FON1253, FON1307, FON1371)

- STANAG 4754: NATO Generic Vehicle Architecture (NGVA) for Land System

| Cable Type / Protocol | Mode Type | Core/Cladding/Coating | Jacket Color | Gore Part Number |

|---|---|---|---|---|

| 1.8 mm Simplex | Single Mode | 9/125/245 | Yellow | GSC-13-84689-04 |

| Single Mode | 9/125/245 | Violet | GSC-13-84689-07 | |

| OM1, Multi-Mode, Graded Index | 62.5/125/245 | Yellow | GSC-13-84640-04 | |

| OM1, Multi-Mode, Graded Index | 62.5/125/245 | Violet | GSC-13-84640-07 | |

| OM2, Multi-Mode, Graded Index | 50/125/245 | Yellow | GSC-13-84639-04 | |

| OM2, Multi-Mode, Graded Index | 50/125/245 | Violet | GSC-13-84639-07 | |

| OM3, Multi-Mode, Graded Index | 50/125/245 | Yellow | GSC-13-84943-04 | |

| OM3, Multi-Mode, Graded Index | 50/125/245 | Violet | GSC-13-84943-07 | |

| OM3, Multi-Mode, Graded Index | 50/125/245 | Violet | GSC-13-84943-17a | |

| OM4, Multi-Mode, Graded Index | 50/125/245 | Yellow | GSC-13-85423-04 | |

| OM4, Multi-Mode, Graded Index | 50/125/245 | Violet | GSC-13-85423-07 | |

| OM5, Multi-Mode, Graded Index | 50/125/245 | Yellow | GSC-13-85868-04 | |

| OM5, Multi-Mode, Graded Index | 50/125/245 | Violet | GSC-13-85868-07 | |

| 1.2 mm Simplex | Single Mode | 9/125/155 | Blue | FON1002 |

| OM1, Multi-Mode, Graded Index | 62.5/125/155 | Blue | FON1003 | |

| Single Mode | 9/125/250 | Blue | FON1253 | |

| OM2, Multi-Mode, Graded Index | 50/125/250 | Blue | FON1307 | |

| OM1, Multi-Mode, Graded Index | 62.5/125/250 | Blue | FON1371 | |

| 0.9 mm Simplex (900 µm) | OM1, Multi-Mode, Graded Index | 62.5/125/245 | Tan | GSC-13-85067-00 |

| OM4, Multi-Mode, Graded Index | 50/125/245 | Tan | GSC-13-85424-00 | |

| Single Mode | 9/125/245 | Tan | GSC-13-85375-00 | |

| OM5, Multi-Mode, Graded Index | 50/125/245 | Tan | GSC-13-85869-00 |

a. Includes a JN1177 marking on the jacket material.

Featured Content

Related Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 455 4684

Have questions or unique requirements?

Our experts are here to guide you.