GORE® HDMI Cables for Aerospace & Defense

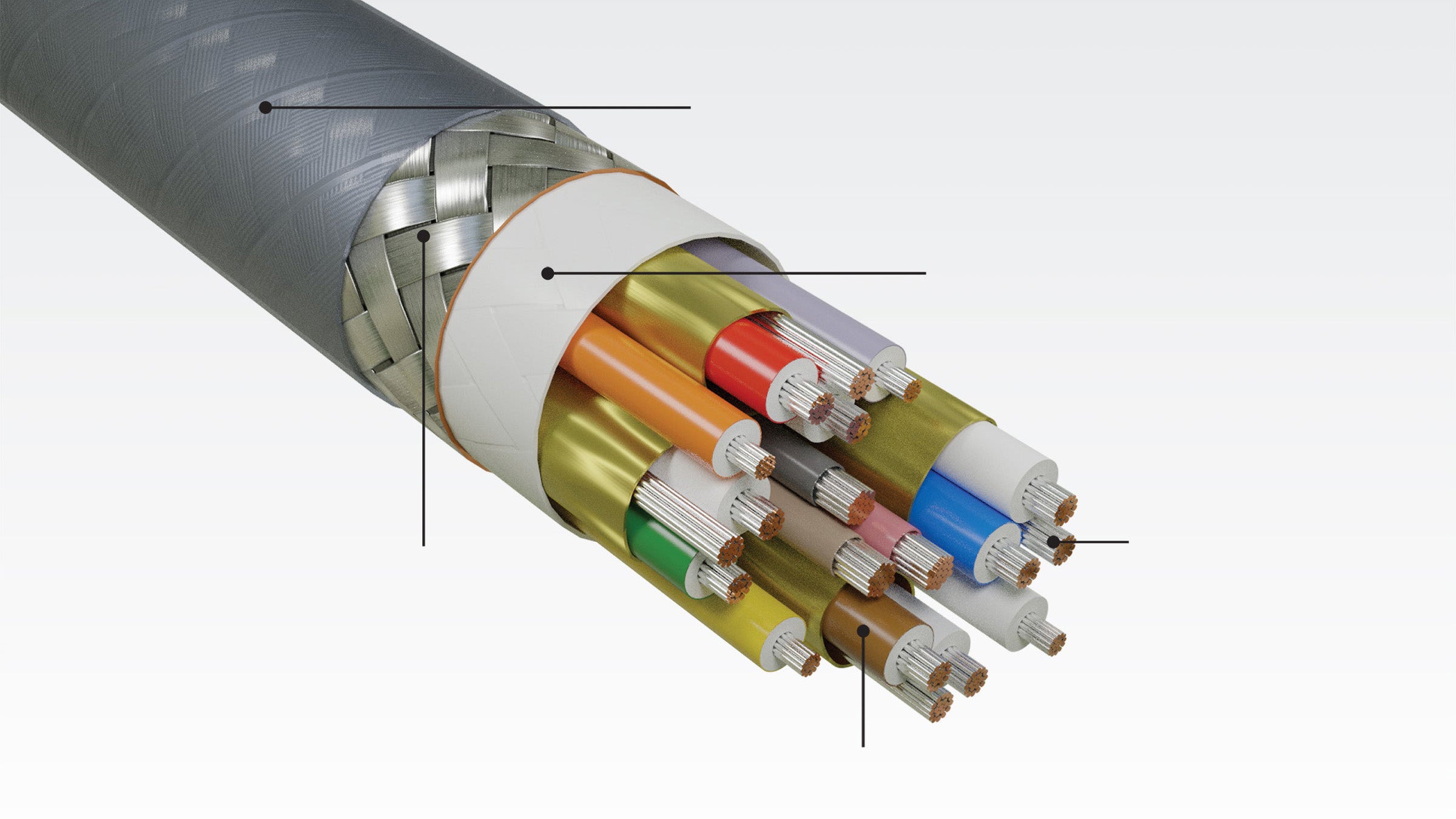

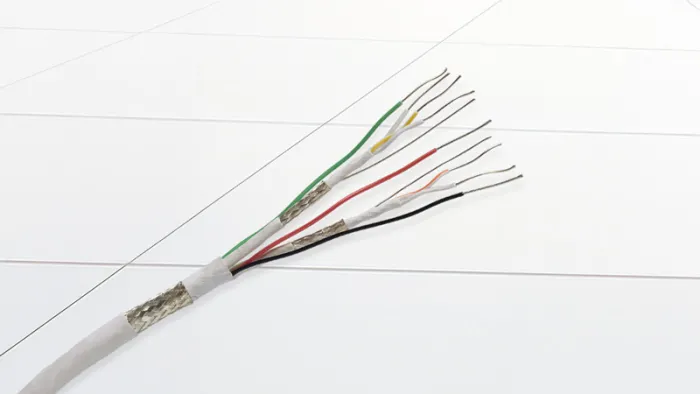

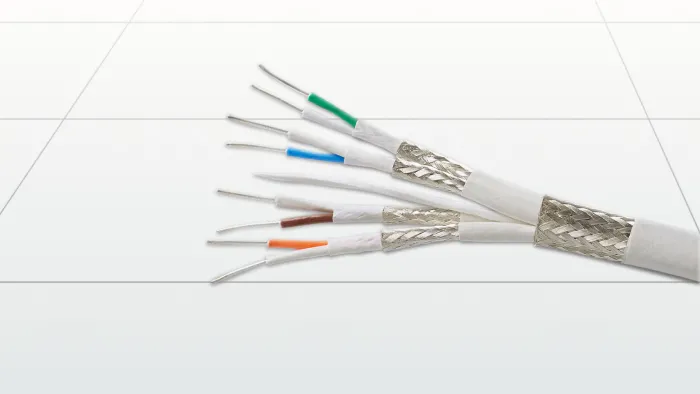

Our low-weight, flexible cable bundles transfer high-speed data and video and reliably support 4K resolution while meeting 1.4 and 2.0 protocol requirements.

High-Definition Displays with Low-Weight, Flexible Construction

GORE® HDMI Cables for 1.4 and 2.0 protocols support a wide array of video applications with crystal-clear high resolution and fast signals up to 18 Gb/s. Our cable bundles also offer a small-diameter, low-weight design with more flexibility to make routing much easier for maintainers.

GORE® High-Speed Data Cables for Aerospace & Defense

Combining dielectric expertise with innovative fluoropolymer materials, we bring a portfolio of standard high data rate cables with proven performance over leading alternatives.

Gore Solutions for Aerospace & Defense

Learn more about Gore’s wide range of components and materials that have been time-tested and proven to aerospace and defense suppliers.

Technical Information

These values demonstrate the electrical, mechanical and environmental performance of GORE HDMI Cables for civilian aircraft, as well as military aircraft and vehicles.

| Elec./Mech./Environ. Property | Value |

|---|---|

| Signal Transmission Speed Gb/s | Up to 18 |

| Standard Impedance Ohms | 100 ± 10 |

| Typical Operating Voltage V | < 15 |

| Nominal Velocity of Propagation % | 80 |

| Nominal Time Delay ns/m (ns/ft.) | 4.10 (1.25) |

| Capacitance pF/m (pF/ft.) | 42.5 (13.0) |

| Maximum Skew Within Pair ps/m (ps/ft.) | 15.0 (4.6) |

| Dielectric Withstanding Voltage Vrms Conductor-to-Conductor Conductor-to-Shield | 1500 1000 |

| Jacket Material | Engineered Fluoropolymer |

| Jacket Color | Gray |

| Conductor | Silver-Plated Copper Alloy |

| Conductor Color-Coding | High-Speed Pairs: Blue/White, Brown/White, Green/White, Red/White Singles: Orange, Violet, White, Yellow Triad: Gray, Pink, Tan |

| Dielectric Material | Expanded PTFE/PTFE |

| Temperature Range °C | -65 to +200 |

Complete the short form below for instant access to a selected drawing with technical specifications from W. L. Gore & Associates.

GORE HDMI Cables have gone through extensive qualification testing to ensure they meet the most current aerospace and defense standards, including:

- ABD0031 (AITM 2.0005); BSS7230; FAR Part 25, Appendix F, Part: Flammability

- ABD0031 (AITM 3.0005); BSS7239: Toxicity

- ABD0031 (AITM 3.0008B); BSS7238; FAR Part 25, Appendix F, Part V: Smoke Density

- ANSI/NEMA WC 27500: Environmental Testing, Jacket and Marking

- SAE AS4373™: Test Methods for Insulated Electric Wire (Contact Gore for available data)

GORE HDMI Cables for avionics and vetronics are available in a standard size.

RCN9121

Featured Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 455 4684

Have questions or unique requirements?

Our experts are here to guide you.