IP and NEMA Ratings: How They Can Guide Your Vent Selection

A critical aspect of vent selection begins with defining the level of protection your application, device or housing requires. There are two common standards — one international, the other primarily North American — for defining levels of protection:

The Ingress Protection (IP) Standard (IEC-60529)

This international standard, commonly called "IP ratings" defines the degree to which an enclosure protects against:- foreign solid objects (access to hazardous parts and against solid foreign objects)

- ingress of water

IP-rated vents are those that deliver specific levels of protection against ingress of particles or liquids.

The NEMA 250 Standard for protecting electrical enclosures

This North American standard, from the National Electrical Manufacturers Association (NEMA), defines the degree to which an electrical enclosure protects against:- ingress of particles or liquids

- incidental contact by personnel

NEMA 250 also includes many additional requirements for things like enclosure construction and enclosure resistance to other environmental challenges such as corrosion resistance, gasket aging, oil resistance and external icing.

While both IP and NEMA define resistance to ingress of solids and fluids, the standards are not identical: NEMA enclosure classifications involve additional testing not included in IP. For this reason, IP ratings cannot be “converted” to NEMA ratings. However, there are minimum NEMA protection ratings that will meet or exceed a given IP code.

Whether your designs must meet the standards for NEMA or IP-rated enclosures, our representatives and application engineers can help you select the optimum venting solution. We are eager to collaborate with you, from design through testing and manufacturing integration, to meet your requirements.

Let us help you choose the right vent to meet your device's IP or NEMA standards.

More About IP Ratings and What They Mean

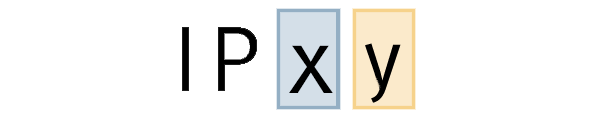

IP ratings typically use a two-digit code, such as “IP68,” to specify the type, and level, of environmental protection an enclosure provides.

The Key to Ingress Protection Ratings

| Type of Protection | x = Foreign Solid Objects | y = Liquids and Moisture |

|---|---|---|

| Level of Protection | 0 None | 0 None |

| 1 Foreign solid objects (≥50mm) | 1 Drops of water or condensation (falling vertically) | |

| 2 Foreign solid objects (≥12.5mm) | 2 Direct sprays of water (up to 15&° from vertical) | |

| 3 Foreign solid objects (≥2.5mm) | 3 Direct sprays of water (up to 60&° from vertical) | |

| 4 Foreign solid objects (≥1.0mm) | 4 Direct sprays of water (from all directions) | |

| 5 Dust (limited, non-harmful ingress) | 5 Low-pressure water jets (from all directions) | |

| 6 Dust (zero dust ingress) | 6 High-pressure water jets (from all directions) | |

| 7 Temporary immersion in water (up to 1m) | ||

| 8 Continuous immersion in water (up to 2m; user-defined) | ||

| 9k High-pressure steam jets (from all directions) |

| NEMA | IEC Enclosure Classification Designation |

|---|---|

| 1 | IP20 |

| 2 | IP22 |

| 3 | IP55 |

| 3X | IP55 |

| 3R | IP24 |

| 3RX | IP24 |

| 3S | IP55 |

| 3SX | IP55 |

| 4 and 4X | IP66 |

| 5 | IP53 |

| 6 | IP67 |

| 6P | IP68 |

| 12 and 12K | IP54 |

| 13 | IP54 |

GORE Protective Vents for IP-Rated Enclosures

When selecting a vent to meet the demands of your IP-rated enclosure, it’s essential to consider factors such as housing design, vent size and environmental challenges. All will affect a vent’s ability to meet a given IP rating in a given application. For example:

- IP65 electronic enclosures must admit no dust, and withstand low-pressure water jets: this level of protection is needed for applications such as outdoor environmental lighting around fountains, or residential solar panels that may be hosed down periodically.

- An IP66 outdoor enclosure also admits no dust, and withstands high-pressure water jets from all directions. This is the rating needed for applications that may be cleaned frequently by high-pressure sprays, such as commercial storefront lighting enclosures or industrial vehicles.

- An IP67 vent admits no dust, and withstands temporary immersion in up to 1 meter of water: ideal for heavy-duty equipment that may ford deep puddles or streams, as well as telecom equipment in locations that may experience heavy rain runoffs or temporary water pooling.

- An IP68 electrical enclosure admits no dust, and withstands continuous immersion in water up to 2 meters deep, for varying lengths of time. This level of protection is for applications where extended lifetimes are needed, despite being exposed to water challenges.

In order for a vent to be able to meet a certain IP rating, the key parameters are the housing design and the part size.

Gore has an extensive portfolio of venting products engineered to meet or exceed the most demanding performance standards, for virtually every application need.

Our vent materials and constructions are rigorously tested and characterized against international standards for dust, splash, and immersion protection as well as acoustic performance. We also employ additional testing protocols, developed by Gore engineers, which more effectively measure the impact of real-world environmental challenges on vents, housing performance, and application longevity. To learn more about how Gore strives to exceed the standards in portable electronic devices, download our white paper:

White Paper: Improved Consistency in Testing

Whether your device and housing must meet IP54, IP64, IP65, IP67, IP68, or IP69k standards our representatives and application engineers can help you determine if a vent is needed and if so, help you select the optimum venting solution. We are eager to collaborate with you, from design through testing and manufacturing integration, to meet those requirements.

GORE Protective Vents offers multiple solutions for all these IP rating requirements.

Our vent materials and constructions are rigorously tested to meet or exceed IP standards for dust, splash and immersion protection.

| GORE Protective Vents | Humidity Testing IEC 60 068-2-78 | Ingress Protection Testing | ||||||

|---|---|---|---|---|---|---|---|---|

IEC 60529 | ISO 20653 | |||||||

| Accelerated Aging 85 °C / 85% rH / 1000 hrs | IP64 | IP65 | IP66 | IP67 | IP68 2m/1hr | IP68 up to 72hr | IP69K | |

| Adhesive Series | ||||||||

| VE8 | ✓ (I) | ✓ (I) | ||||||

| VE7 | ✓ (I & E) | ✓ (E) | ✓ (E) | ✓ (I & E) | ✓ (I & E) | |||

| VE9 | ✓ (I & E) | ✓ (E) | ✓ (E) | ✓ (I & E) | ✓ (I & E) | |||

| Snap-In Series | ||||||||

| GORE® PolyVent Hysi | ✓ | ✓ | ✓ | ✓ | ||||

| GORE® PolyVent XS | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ * | ||

| GORE® PolyVent Standard | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ * | ||

| GORE® PolyVent High Airflow | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ * | ||

| Screw-In Series | ||||||||

| GORE® PolyVent XS | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| GORE® PolyVent Standard | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| GORE® PolyVent High Airflow | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| GORE® PolyVent XL | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| GORE® PolyVent Stainless Steel | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| GORE® PolyVent Ex+ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

(I) = Interior mounting only

(E) = Exterior mounting only

(I & E) = Interior or Exterior mounting

* Depending on housing geometry.

Whether your device and housing must meet IP64, IP65, IP67, IP68 or IP69k standards, our representatives and application engineers can help you select the optimum venting solution.

More about NEMA ratings and what they mean

NEMA enclosure classifications use a numeric scale, from 1–13, to specify the types and levels of environmental protection an enclosure provides to the internal electronics.

This table briefly summarizes the levels of protection typically required to seal or vent enclosures that contain electronics. Complete definitions, features and test criteria for all NEMA enclosure types are at www.nema.org.

What's the Difference?

If one or more letters follow the numeral, it indicates a variant in NEMA protection levels. For example, NEMA 4X includes the same protections as NEMA 4, but with an added requirement for protection against corrosive agents.

| NEMA Enclosure Rating | Non-Hazardous Location | Enclosure protects equipment from: | ||

|---|---|---|---|---|

| Ingress of Solid Foreign Objects | Ingress of Water | Other Damaging Conditions | ||

| 1 | Indoor | Falling dirt (but not dust-tight) | Incidental contact with equipment | |

| 2 | Indoor | Falling dirt. | Incidental contact with equipment. Dripping. | Severe condensation, as in cooling & laundry rooms. |

| 3 | Indoor or Outdoor | Falling dirt, windblown dust. | Rain, sleet, snow. | External ice buildup. |

| 3X | Indoor or Outdoor | Falling dirt, windblown dust. | Rain, sleet, snow. | Corrosive agents. |

| 3R | Indoor or Outdoor | Falling dirt (but no dust protection). | Dripping/light splashing. Rain, sleet, snow. | External ice buildup. |

| 3RX | Indoor or Outdoor | Falling dirt (but no dust protection). | Dripping/light splashing. Rain, sleet, snow. | Corrosive agents. |

| 3S | Indoor or Outdoor | Falling dirt, windblown dust. | Dripping/light splashing. Rain, sleet, snow. | External enclosure mechanisms operate when ice-laden. |

| 3SX | Indoor or Outdoor | Falling dirt, windblown dust. | Dripping/light splashing. Rain, sleet, snow. | Corrosive agents. |

| 4 | Indoor or Outdoor | Falling dirt, windblown dust. | Rain, sleet, snow. Splashing or hose-directed water. | External ice buildup. |

| 4X | Indoor or Outdoor | Falling dirt, windblown dust. | Rain, sleet, snow. Splashing or hose-directed water. | Corrosive agents. |

| 5 | Indoor | Falling dirt, settling airborne dust, lint, fibers, and flyings. | Dripping/light splashing. | |

| 6 | Indoor or Outdoor | Falling dirt. | Dripping/light splashing. Rain, sleet, snow. Hose-directed water. | External ice buildup. Occasional temporary submersion in water at limited depth. |

| 6P | Indoor or Outdoor | Falling dirt. | Dripping/light splashing. Rain, sleet, snow. Hose-directed water. | Prolonged submersion and corrosive agents. |

| 12 | Indoor | Falling dirt, circulating dust, lint, fibers, and flyings. | Dripping/light splashing | For enclosures WITHOUT knockouts. |

| 12K | Indoor | Falling dirt, circulating dust, lint, fibers, and flyings. | Dripping/light splashing | For enclosures WITH knockouts. |

| 13 | Indoor | Falling dirt, circulating dust, lint, fibers, and flyings. | Dripping/light splashing | Spraying, splashing, and seepage of oil and noncorrosive coolants. |

Gore has an extensive portfolio of venting products engineered to meet or exceed the most demanding performance standards, for virtually every application need.

Our vent materials and constructions are rigorously tested and characterized against multiple international and North American standards for dust, splash, and immersion protection.

We also employ additional testing protocols, developed by Gore engineers, which more effectively measure the impact of real-world environmental challenges on vents, enclosure integrity and application longevity.

To learn more about how Gore strives to exceed the standards by venting electronic devices, download our white papers:

When your device and housing must meet IP or NEMA standards, our representatives and application engineers can help you determine if a vent is needed and if so, help you select the optimum venting solution. We are eager to collaborate with you, from design through testing and manufacturing integration, to meet your requirements.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.