Outdoor Electronic Vents

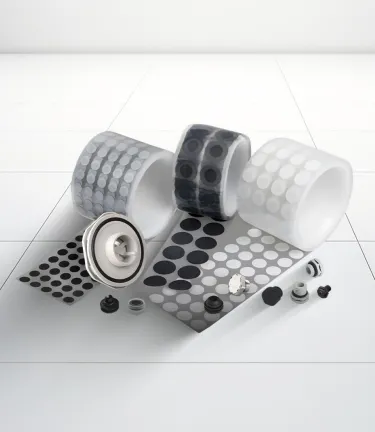

GORE® Protective Vents improve the reliability and longevity of sensitive electronics by protecting them from harsh environmental conditions.

Safeguarding Outdoor Electronics with GORE® Protective Vents

Gore, a global leader in venting technology, delivers innovative solutions that improve the reliability and lifespan of outdoor electronic devices. Our protective vents effectively manage pressure, condensation, and contamination in applications such as battery, lighting, energy, telecom, heavy machinery, and security systems.

Available in adhesive, screw-in, and snap-in configurations, these vents are designed for easy integration and cost efficiency. For customized needs, we collaborate with clients from design through to production.

Featured Products

Advanced Venting, Thermal Insulation, and Protection Solutions for the Electronics Industry

Gore is a leader in the electronics industry, providing advanced solutions for venting, thermal insulation, and ingress protection. Our technologies enhance acoustic performance, regulate temperature, and shield against contaminants and pressure changes—improving the reliability and durability of everything from portable devices to critical electronic systems around the world.

Proven Venting Strategies to Improve Electronics’ Reliability

Watch three expert sessions on-demand