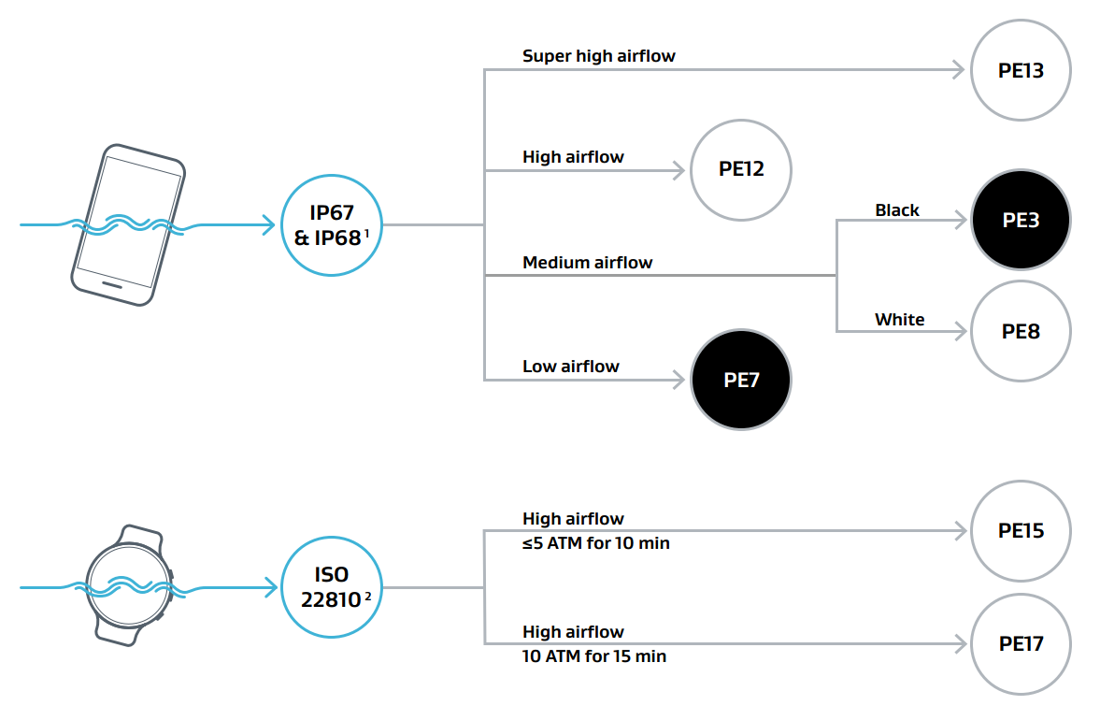

GORE® Pressure Vents for Portable Electronics

GORE® Pressure Vents provide superb reliability for portable electronics through exceptional balance of airflow and water protection.

Unparalleled Airflow, Fast Pressure Equalization

GORE Pressure Vents are engineered to provide optimum airflow within the available design envelope without compromising the required level of ingress protection. They help to equalize pressure fast, minimizing the pressure differentials that can weaken the gaskets and seals within a device, create transducer bias and compromise acoustic performance.

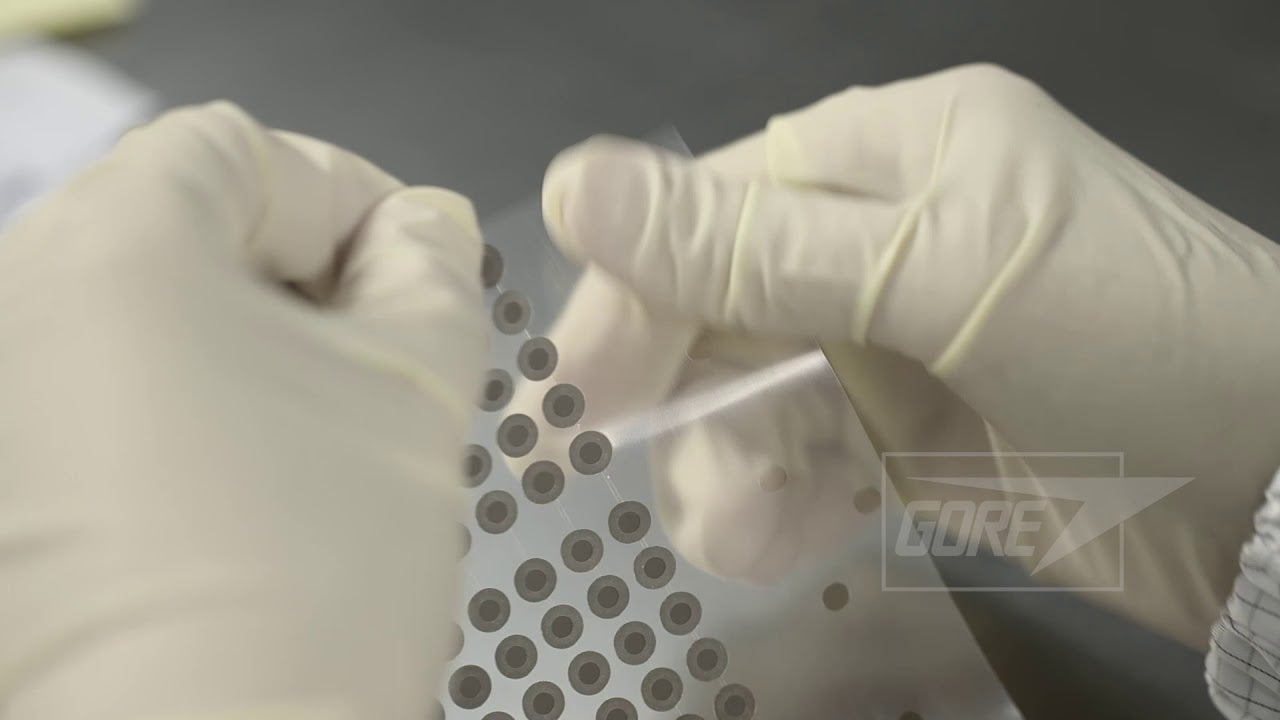

Installing GORE Pressure Vents

GORE® Pressure Vents have been developed to easily be applied manually or as part of high-volume manufacturing processes and automated installation procedures.

Technical Information

| Application | Smartphones, Two-Way radios, Scanners | Wearables | |||||

|---|---|---|---|---|---|---|---|

| Characteristics/ Performance | PE13 | PE12 | PE8 | PE3 | PE7 | PE15 | PE17 |

| IP rating (IEC 529, 2nd)1 | IP67, IP682 | IP67, IP682 | IP673 | IP67, IP684 | IP67, IP68 | ||

| ISO rating (ISO 22810)10 | N/A | N/A | N/A | N/A | 50 m water @ 10 min8 | 100 m water @ 15 min9 | |

| Typical airflow (dp = 70 mbar) | 19,000 ml/min/cm2 | 10,000 ml/min/cm2 | 3,300 ml/min/cm2 | 3,300 ml/min/cm2 | 290 ml/min/cm2 | 380 ml/min/cm2 | 290 ml/min/cm2 |

| Reference thickness5 | 0.24 mm | 0.24 mm | 0.27 mm | 0.27 mm | 0.34 mm | 0.29 mm | 0.42 mm |

| Adhesive type6 | Silicone/ Acrylic | Silicone/ Acrylic | Acrylic | Silicone | Acrylic | ||

| Membrane type | ePTFE | ||||||

| Membrane characteristic | Oleophobic | ||||||

| Membrane color | White | Black | White | ||||

| Support material | PET | PET Non-woven | None | PET | |||

| Part orientation | Internal mount with ePTFE facing environment | Mount on the interior or exterior of the housing | Internal mount with ePTFE facing environment and back pressure on captive ring is required11 | ||||

| Adhesive temperature range | -40 °C to 100 °C | ||||||

| RoHS7 | Meet threshold requirements | ||||||

- IP ratings depend on housing design and part size.

- Extended immersion testing: 1.5 m water immersion for 30 minutes.

- PE8 and PE3 can meet IP68 (1.5 m water @ 30 minutes) with certain custom design conditions. Please contact Gore associates for details.

- Extended immersion testing: 2 m water immersion for 1 hour. PE7 can also meet IP65 and IP66 under external mount condition only.

- Actual thickness may vary due to the compressibility of nonwoven, ePTFE and adhesive layers.

- A wide range of options available as a custom product.

- To the best of our knowledge, the parts listed above do not have any restricted substances above the maximum concentration values listed in RoHS Directive 2011/65/EU.

- Extended immersion testing: 50 m water immersion for 10 minutes with back pressure on captive ring.

- Extended immersion rating: 100 m water immersion for 15 minutes with back pressure on captive ring.

- In compliance with ISO22810:2010(E) test method 4.3.2 Water resistance to overpressure.

- PE7 can also be mounted on the interior of the housing, and have therefore the waterproof adhesive facing the interior environment.

This information is based on our current level of knowledge and does not constitute a representation or warranty beyond those contained in our standard terms and conditions.

Gore monitors and strives to comply with all regulations applicable to our products.

We have worked with our suppliers to eliminate PFOA from our supply chain. Our products meet EU REACH regulations EU 1907/2006 and EU 2019/2021.

Predicting the conditions your product will encounter can be difficult. Our experienced team of application experts will work with you to select the right vent, optimized to your unique requirements.

Factors that might be considered include:

- Product dimensions (device air volume)

- How your product will be used

- Potential altitude changes

- Minimum and maximum temperatures it may face

- Time between minimum and maximum temperature exposures

- Target equalization time

- Required liquid, particulate and contaminant protection levels

- Vent mounting surfaces and required adhesives

See the Difference

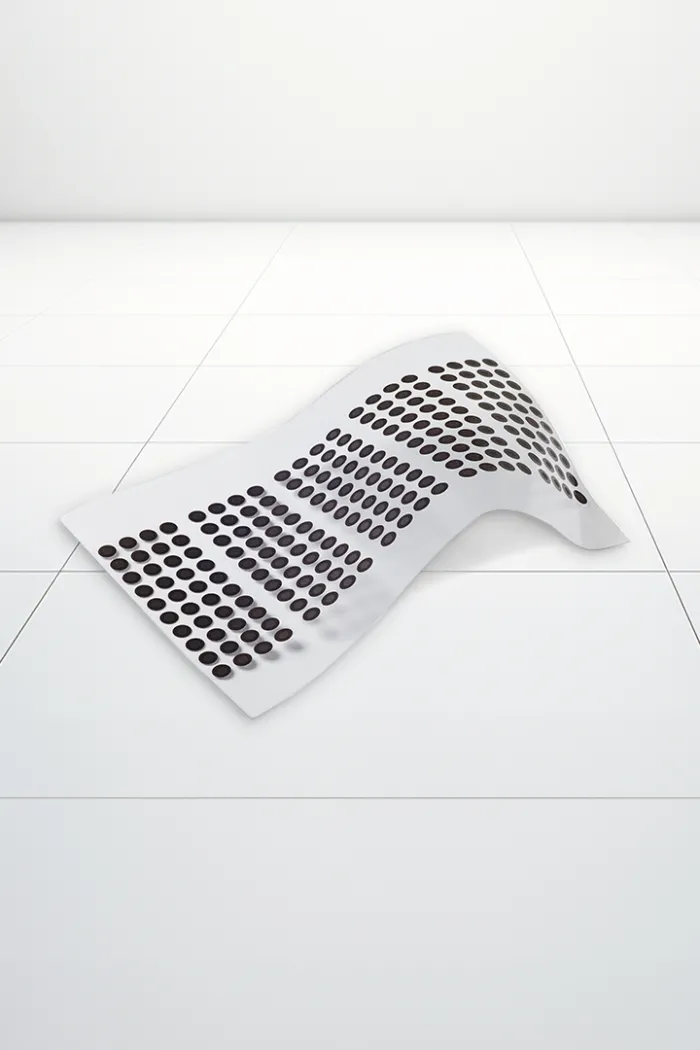

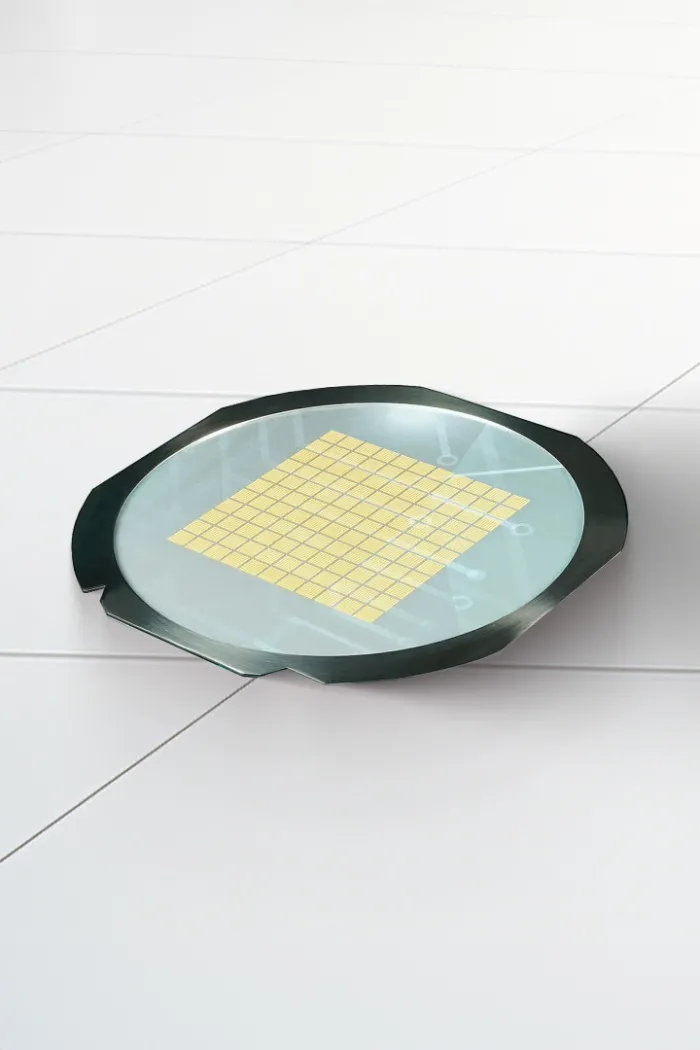

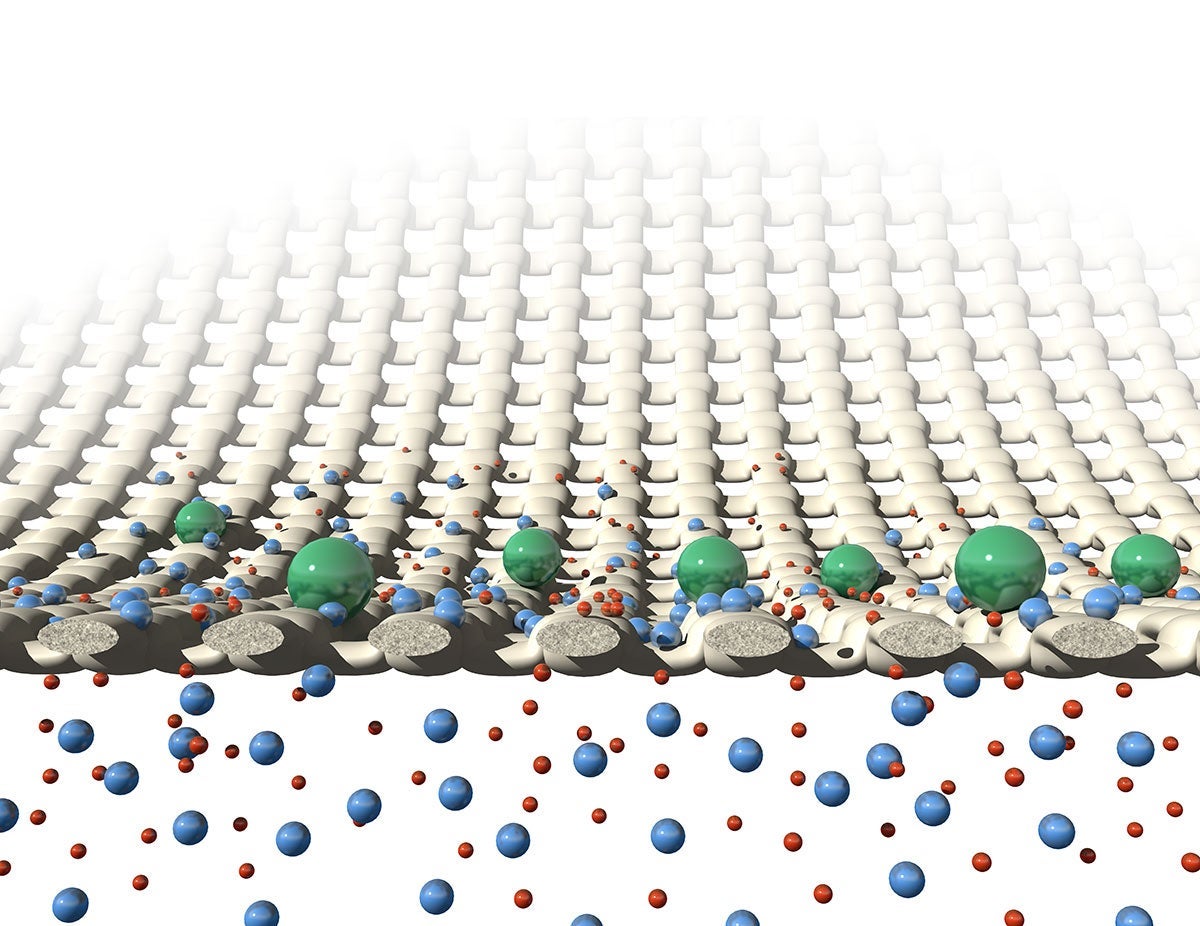

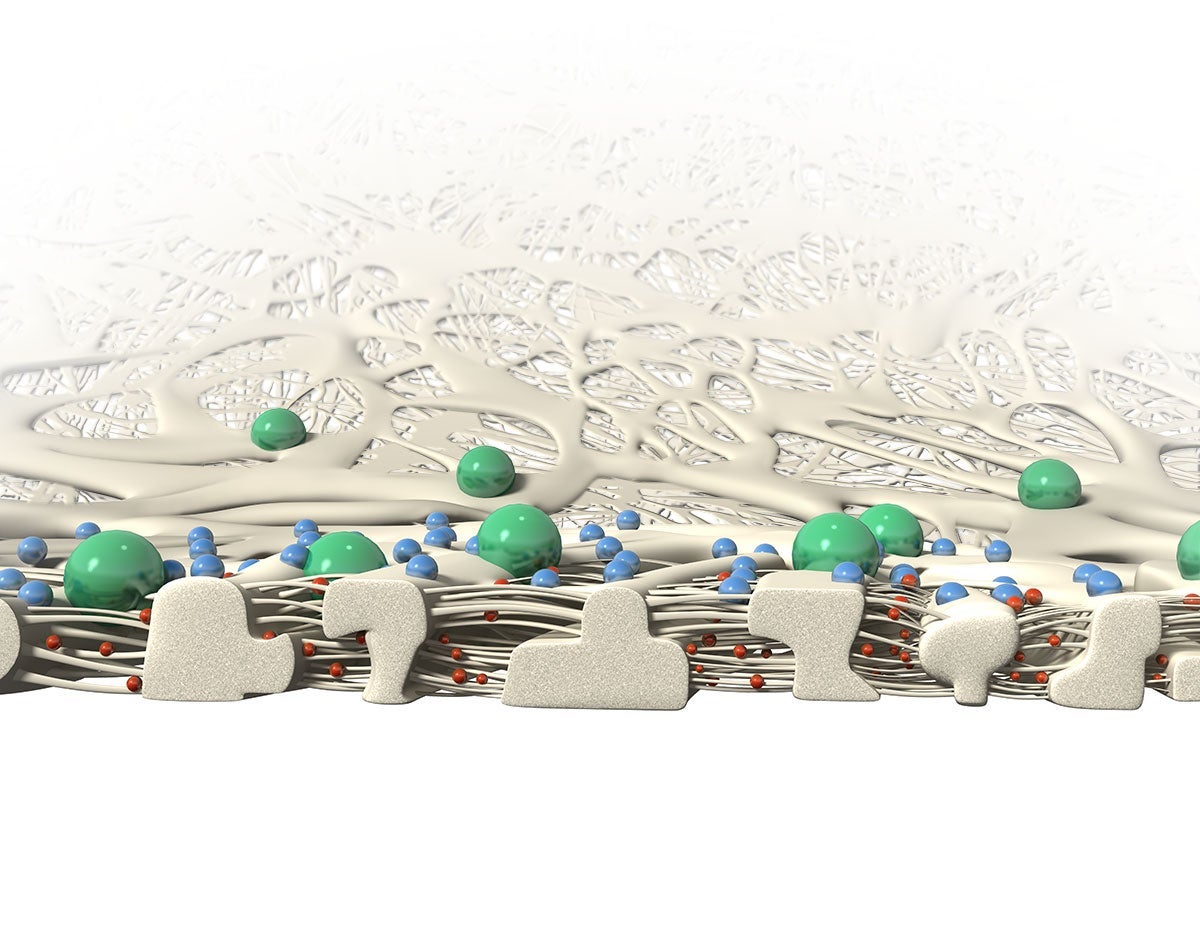

Compared to woven designs (FIG1) which can block airflow when particles accumulate or pass through the surface, Gore’s unique membrane design (FIG2) uses a tortuous path structure to capture particles of various shapes and sizes while maintaining consistent airflow.

FIG 1

FIG 2

| Dimension (mm) | Part Number | |||||||

|---|---|---|---|---|---|---|---|---|

| Inner Diameter | Outer Diameter | PE13 | PE12 | PE8 | PE3 | PE7 | PE15 | PE17 |

| 1.6 | 4.2 | - | - | - | - | - | - | - |

| 2.0 | 5.0 | PE130205 | PE120205 | PE80205 | PE30205 | - | - | - |

| 3.0 | 6.0 | PE130306 | PE120306 | PE80306 | PE30306 | PE70306 | - | - |

| 5.0 | 9.4 | - | - | - | PE30509 | - | - | - |

| 5.5 | 10.2 | - | - | PE80510 | - | PE70510 | - | - |

| 1.6 | 3.8 | - | - | - | - | - | PE151.63.8 | - |

| 2.0 | 4.2 | - | - | - | - | - | PE152.04.2 | PE172.04.2 |

Available in custom and standard sizes to give manufacturers greater design flexibility — to either reduce the number of pressure vents used in their devices or reduce the size of pressure vents for devices with limited internal space — without reducing effectiveness.

Gore application engineers are also available to assist in selecting the right solution for your specific application requirements.

Case Studies

Related Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 410 506 7812

Have questions or unique requirements?

Our experts are here to guide you.