System-on-Chip (SoC) Throttling

Improve System-on-Chip Thermal Management

Within a mobile electronic device, the System on a Chip (SoC) is a group of processors on a single chip which functions as a microcontroller. It integrates all components needed to run the system, from data or graphics processing to memory or secondary storage, as well as other circuits.

Because the SoC is controlling a multitude of device functions, the SoC is often the component generating the most heat. As such, it’s a prime candidate for causing surface hot spots on a mobile electronic device. Hot spots must be less than ~45 °C to be considered safe surface temperatures. To avoid exceeding that limit, SoC performance must be throttled back, reducing power output.

For this reason, thermal management for SoCs is incredibly important to thermal engineers for smartphones, laptops, smart watches, AR/VR devices, and other mobile devices. Effective thermal management begins with analyzing SoC heat outputs.

SoC Heat Outputs

Analyzing SoC Heat Outputs

To perform the thermal analysis of a System on a Chip is not trivial. The chip’s heat output can vary, depending upon how it is being used. If it is processing large amounts of data it may have different power requirements than if it is processing high quality graphics, with the higher-power situation leading to more heat output.

In order to do a thermal measurement for an SoC, IR cameras can be used to get a general idea of the heat signature and thermocouples can be used to get an exact measurement of the temperature of the SoC output.

Dissipating SoC Heat Outputs

Once the thermal analysis of the SoC is complete, thermal engineers will look for opportunities to facilitate movement of heat away from the SoC so it can run at higher power for longer, and avoid or delay reaching the throttle threshold.

- Typically, materials like TIMs and thermal pastes will be used to connect the SoC to a spreader like graphite, heat pipes, or vapor chambers. These materials will spread the heat away from the SoC to cooler regions of the device.

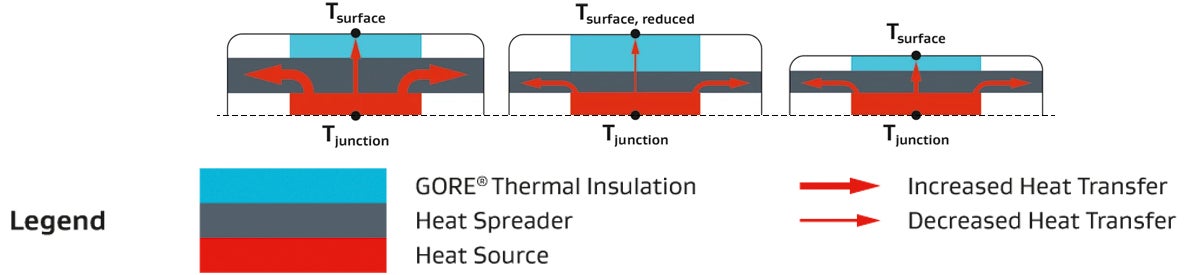

- In addition, GORE® Thermal Insulation can be used to prevent a hot SoC from causing a hot spot on the surface of the device, which would cause the SoC performance to throttle back, based on software algorithms.

GORE Thermal Insulation can lower the surface temperature, and when used in combination with graphite, can allow for an increase the peak performance of the SoC, or increase the length of time spent at a specific power output level before throttling occurs.

Improve Thermal Management Without Compromises

Combining GORE Thermal Insulation with graphite lets designers replace the large air gap with a thinner piece of insulation that leaves space to add more graphite. This combined solution can help to optimize performance for end-users, reduce surface hot spot temperatures, or enable development of thinner high-performance devices.

Increase Performance with | Reduce Hotspot Temperature | Thinner Product Design with |

|---|---|---|

|

|

|

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.