Laptop Heat Dissipation

Gain Sustained Peak Performance with Gore Thermal Management Solutions

Laptop heat dissipation is one of the biggest issues in laptop development. To help with PC-case thermal management, laptops have used a variety of materials and techniques including graphite, heat pipes, vapor chambers, fans, thermal interface materials (TIMs), and thermal pastes. Currently, laptop thermal engineers are integrating GORE® Thermal Insulation into their designs to provide a thermal solution that is the most effective laptop heat disperser.

New Options for Laptop Thermal Management

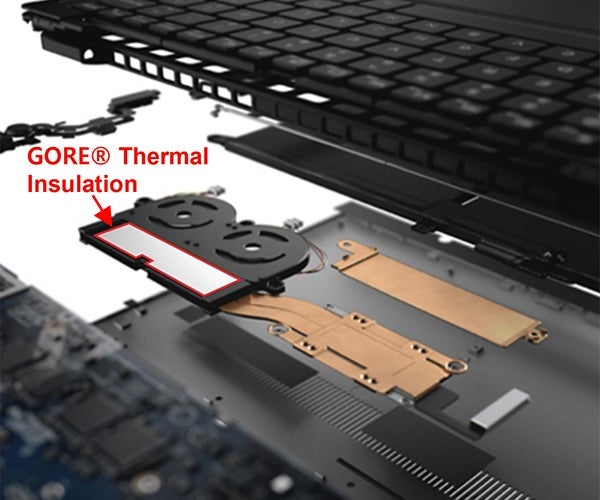

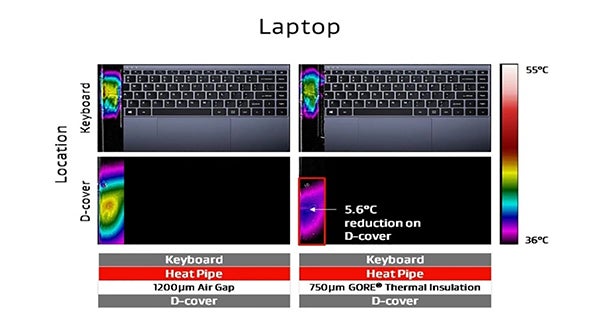

GORE Thermal Insulation can be used to block heat from reaching the surface of the device. The thermals of a PC case are often a point of concern due to prolonged contact while typing, or when the device is used in a lap. Heat spreaders are most often used to disperse laptop heat, while insulation is used to prevent localized hot spots from harming users. Insulation can also be used in combination with spreaders in order to better spread the heat.

The memory in a laptop often produces a high heat load. Laptop memory heat spreaders are used to draw heat away from the memory area and move it to another area. Adding GORE Thermal Insulation to these laptop RAM heat spreader designs can help to further reduce hot spots on the laptop case.

GORE Thermal Insulation can also be used in conjunction with vapor chambers in laptops. While vapor chambers excel at moving heat away from high-power components using two-phase cooling technology, the materials used to construct a vapor chamber are thermally conductive in the through-plane direction. This can allow heat to reach the laptop case surface, creating hot spots. GORE Thermal Insulation can be placed atop specific portions of a vapor chamber to increase the efficiency at which the vapor chamber spreads heat, and to decrease hot spot temperatures.

GORE Thermal Insulation x DELL XPS 13

DELL uses GORE Thermal Insulation to improve performance and slim the design of its laptops.

Thermal Conductivity Lower Than Air

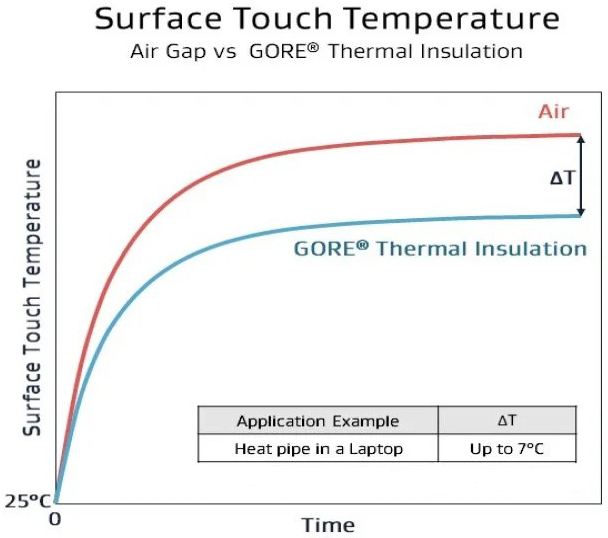

With GORE Thermal Insulation, you can now improve the effectiveness of your thermal spreading solutions. With a through-plane thermal conductivity (kz) significantly lower than air, enabled by premium aerogel technology, GORE Thermal Insulation will enhance the heat-spreading ratio and outperform system-level air gaps. It can be used independently or in conjunction with heat spreaders to create a higher-performing thermal design

Heat Spreading Ratio

(Also known as “Anisotropic Ratio”)

| This ratio characterizes heat dissipation: | |

|---|---|

kxy / kz | kxy - Thermal conductivity in-plane divided by |

| kz - Thermal conductivity through-plane | |

Common heat spreader materials have an intrinsically high anisotropic ratio, which promotes heat to spread and move in-plane. However, compared to insulators, these materials have a very high Kz , which allows heat to move through-plane and reach device surfaces. To compensate for spreaders' high Kz , thermal engineers often design air gaps (with low Kz) above spreaders.

Application Examples: Gore Thermal Insulation in Laptops

Featured Content

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.