GORE® Quad Cables for Aerospace & Defense

Precisely aligned with today’s high-speed serial data and video protocols, our low-dielectric cables offer tighter skew, low crosstalk, controlled impedance and weight savings.

Small, Rugged Quadrax Cables for High-Speed Data & Video Transfer

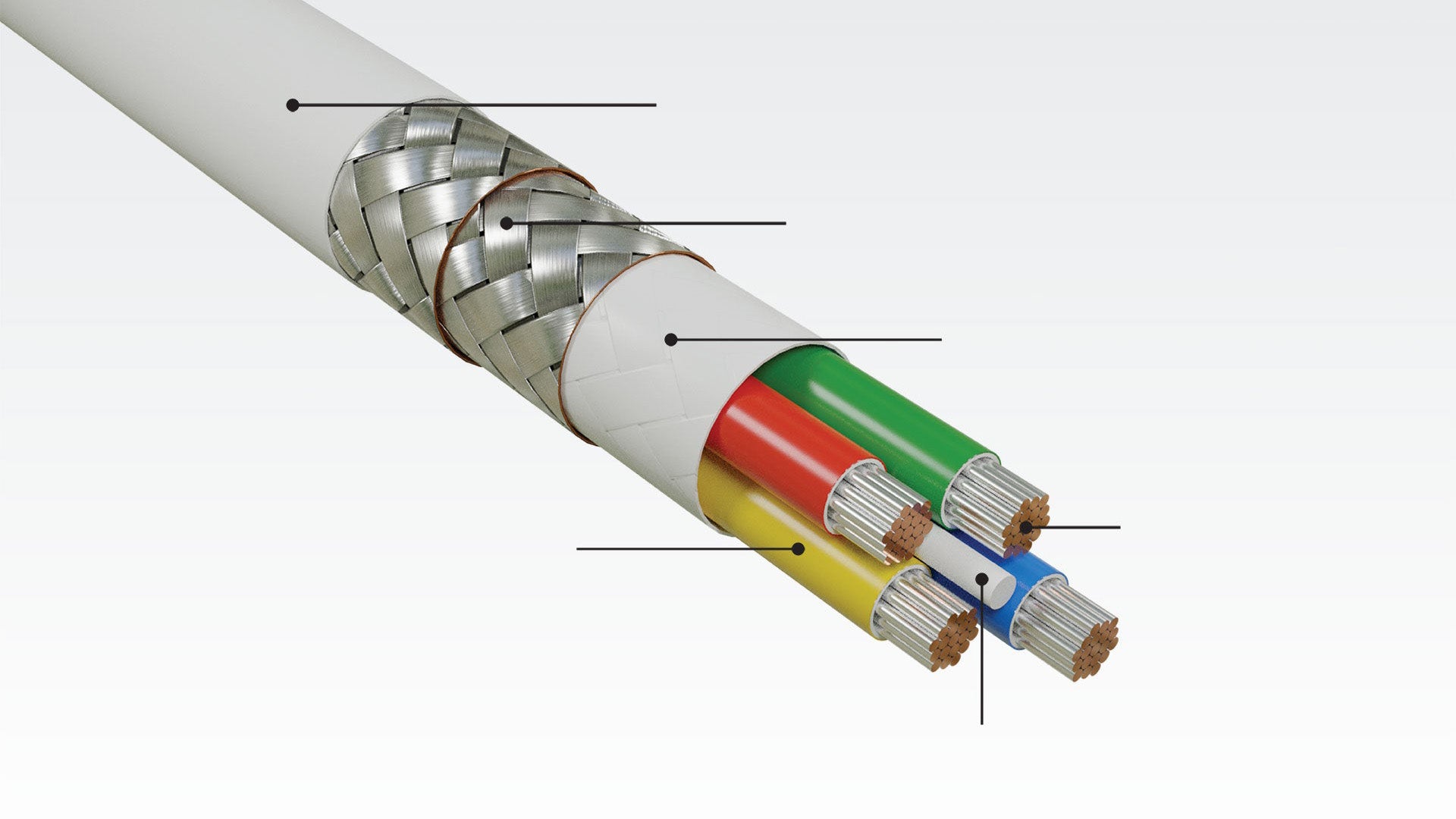

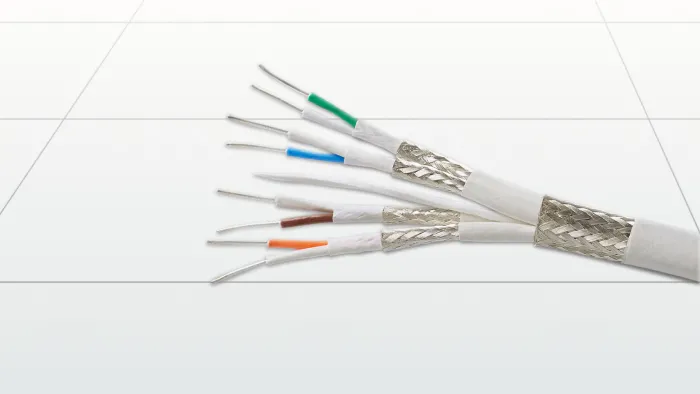

GORE® Quad Cables offer tighter skew requirements with low crosstalk and controlled impedance ideal for high-speed serial data and video protocols. Lighter and more rugged, these quadrax cables feature dual differential pairs that routinely transfer bi-directional signals at speeds up to 1 GHz at lengths up to 30 meters (100 feet).

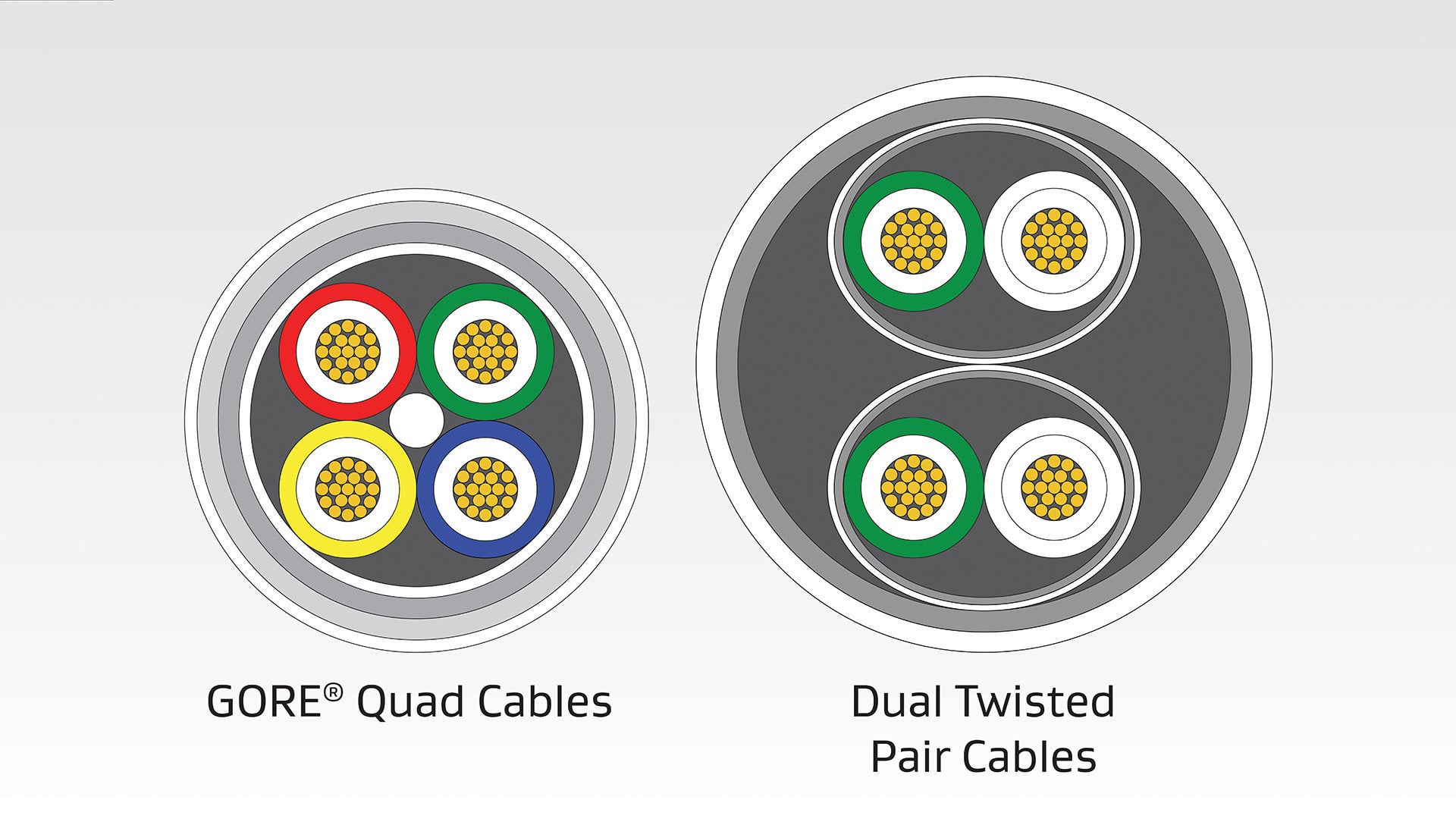

40% smaller

Gore’s unique quadrax design is about 40% smaller than dual twisted pair constructions.

On average, our reduced diameters are proven to save as much as 5.2 kg (11.5 lbs.) per aircraft.

Technical Information

These values demonstrate the electrical, mechanical and environmental performance of GORE Quad Cables for military aircraft and vehicles, as well as commercial aircraft.

| Elec./Mech./Environ. Property | RCN8752 | RCN8982 | RCN8973 |

|---|---|---|---|

| Signal Transmission Speed GHz | Up to 1 | Up to 1 | Up to 1 |

| Standard Impedance Ohms | 100 ± 5 | 100 ± 10 | 100 ± 10 |

| Typical Operating Voltage V | < 48 | < 48 | < 48 |

| Nominal Velocity of Propagation % | > 80 | > 80 | > 80 |

| Nominal Time Delay ns/m (ns/ft.) | 4.10 (1.25) | 4.23 (1.29) | 4.10 (1.25) |

| Capacitance pF/m (pF/ft.) | 50.0 (15.2) | 39.4 (12.0) | 42.7 (13.0) |

| Minimum Near-End Crosstalk (NEXT) dB 10 MHz 100 MHz | 50.0 35.0 | — | — |

| Maximum Skew Within Pair ps/m (ps/ft.) | 13.12 (4.0) | 13.12 (4.0) | 13.12 (4.0) |

| Dielectric Withstanding Voltage Vrms Conductor-to-Conductor Conductor-to-Shield | 1500 | 1500 | 1500 |

| Jacket Material | Engineered Fluoropolymer | Engineered Fluoropolymer | Engineered Fluoropolymer |

| Jacket Color | White (Laser Markable) | White (Laser Markable) | White (Laser Markable) |

| Conductor | Silver-Plated Copper Alloy | Silver-Plated Copper Alloy | Silver-Plated Copper Alloy |

| Conductor Color-Coding | Blue/Red, Green/Yellow | Blue/Orange, Green/Red | Black/Blue, Green/White |

| Dielectric Material | Expanded PTFE/PTFE | Expanded PTFE/PTFE | Expanded PTFE/PTFE |

| Temperature Range °C | -55 to +200 | -55 to +200 | -55 to +200 |

Complete the short form below for instant access to selected drawings with technical specifications from W. L. Gore & Associates.

Meticulously tested and pre-qualified, GORE Quad Cables adhere to the strictest aerospace and defense standards, including:

- ABD0031 (AITM 2.0005); BSS7230; FAR Part 25, Appendix F, Part I: Flammability

- ABD0031 (AITM 3.0005); BSS7239: Toxicity

- ABD0031 (AITM 3.0008B); BSS7238; FAR Part 25, Appendix F, Part V: Smoke Density

- AFDX/ARINC 664, Part 7: Ethernet Networks

- ANSI/NEMA WC 27500: Environmental Testing, Jacket and Marking

- IEEE 802.3: Ethernet 1000BASE-T

- SAE AS4373™: Test Methods for Insulated Electric Wire (Contact Gore for available data)

GORE Quad Cables for avionics and vetronics are available in standard sizes.

RCN8752 (24 AWG)

RCN8982 (26 AWG)

RCN8973 (28 AWG)

Featured Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 455 4684

Have questions or unique requirements?

Our experts are here to guide you.