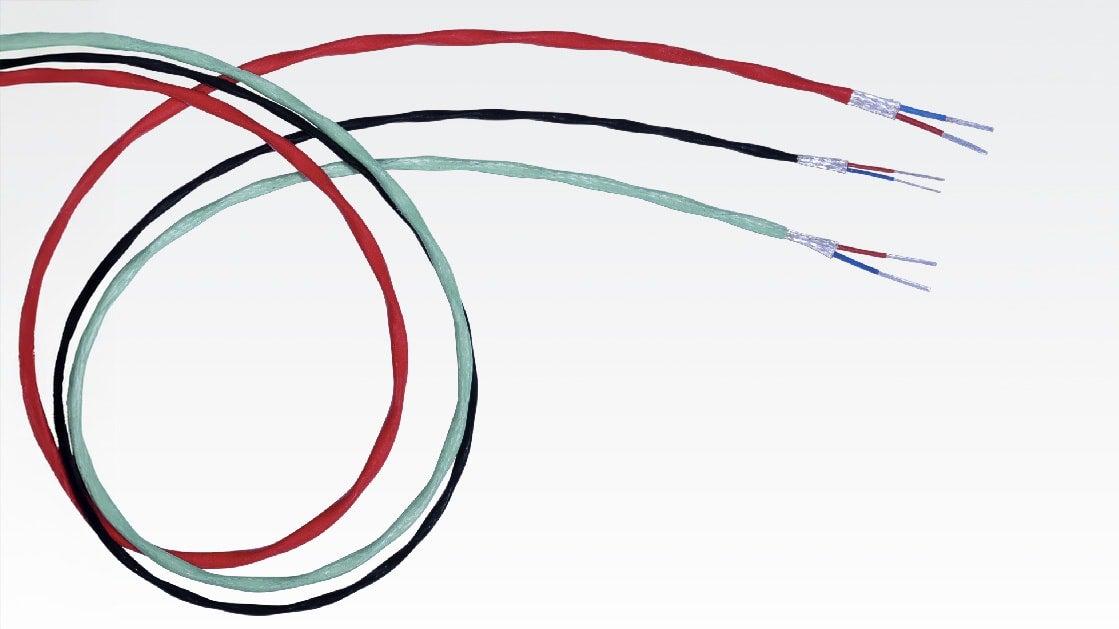

GORE® Space Cables, Type SPM

Our durable cables with excellent signal transmission help integration teams stay on schedule and avoid costly downtime.

Reliable Performance to Minimize Downtime

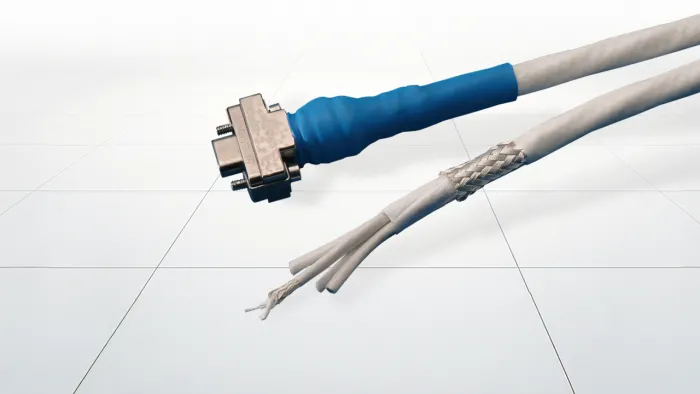

With proven durability, GORE® Space Cables, Type SPM, resist demanding launch and mission stress factors. They have outstanding thermal stability, are chemically inert, and can withstand ATOX in LEO environments. Our cables qualified to ESCC 3901 and on the QPL reliably transmit critical data to minimize downtime during missions.

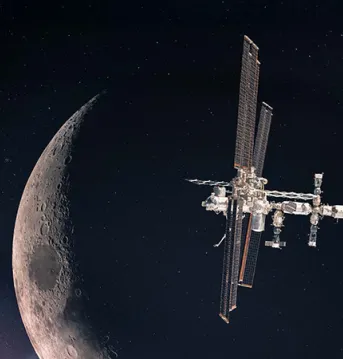

Gore Solutions for Spaceflight

Watch and learn how Gore can help solve the design challenges inherent in space missions, providing decades of proven, reliable solutions to space companies.

Technical Information

GORE Space Cables, Type SPM, meet these technical specifications:

| Elec./Mech./Environ. Property | Value |

|---|---|

| Maximum Operating Voltage Vrms | 600 |

| Cable Jacket Material | PFA |

| Wire Insulation Material | Expanded PTFE (ePTFE) + PTFE + Polyimide |

| Conductor | Silver-Plated Copper or Copper Alloy, True Concentric |

| Temperature Range °C | -200 to +200 |

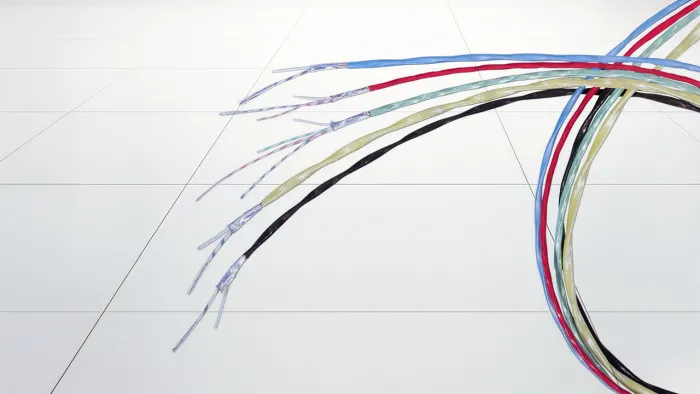

GORE Space Cables, Type SPM, are available in 85 variants from 32 to 12 AWG sizes. When ordering our product, specify ESCC3901018XXB, with “XX” being the appropriate variant number.

Examples include the following:

| Variant Number | Number of Cores | Ordering Number |

|---|---|---|

| 09 | 1 | ESCC390101801B |

| 18 | 2 | ESCC390101818B |

| 24 | 3 | ESCC390101824B |

| 66 | 4 | ESCC390101866B |

| 75 | 5 | ESCC390101875B |

| 85 | 7 | ESCC390101885B |

Featured Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 455 4684

Have questions or unique requirements?

Our experts are here to guide you.