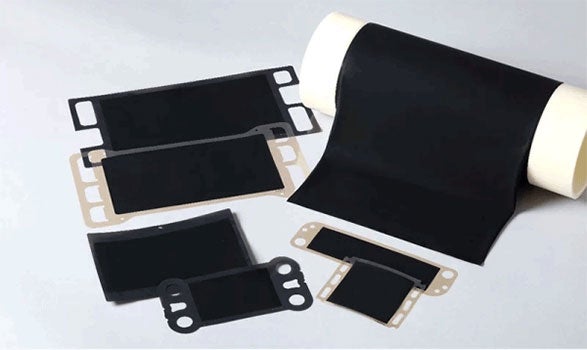

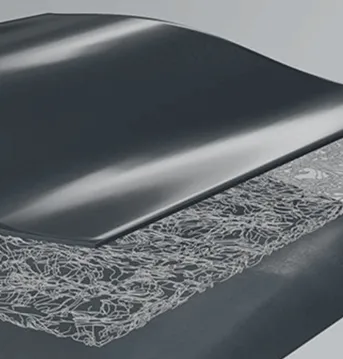

GORE-SELECT® Membranes (PEM) for Fuel Cells

Gore's PEM fuel cell membrane helps OEMs worldwide lower total cost of ownership while increasing fuel efficiency, enabling smaller stacks, and offering greater design flexibility.

Lowering Hydrogen TCO to Enable a Clean Energy Future

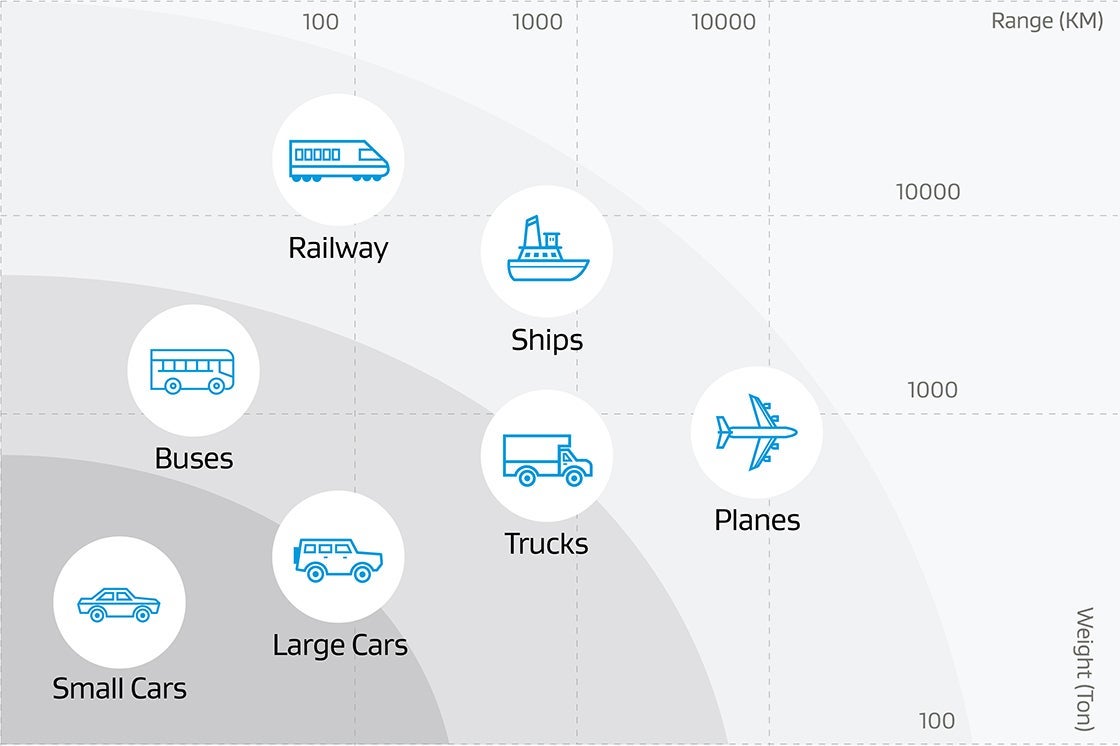

Hydrogen fuel cell technology addresses the challenges OEMs across the automotive and heavy-duty transportation sectors face as they transition to more sustainable and efficient clean energy sources. Proton exchange membrane (PEM) technology has been increasingly used in passenger vehicles due to its high-power density, durability, and efficiency.

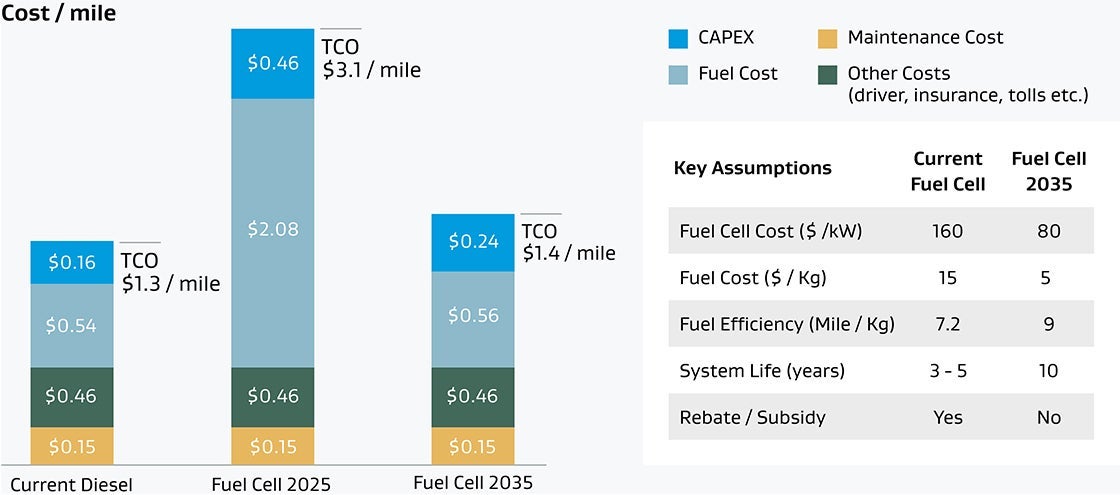

With a 50% decline in total cost of ownership (TCO) forecast over the next decade for fuel cell electric vehicles, PEM will play a pivotal role in the transition to clean transportation.

For heavy-duty vehicles (HDV), fuel cell membranes address the increasing demands for higher power output, extended operation lifecycle, and smaller systems while approaching cost parity with diesel. With the right PEM fuel cell membrane manufacturer, OEMs can minimize trade-offs in achieving minimal TCO.

Powering the Clean Energy Transition With Scalable PEM Technology: Gore is Designed to Deliver

Lowering Hydrogen to Enable a Clean Energy Future

Technical Information

The GORE-SELECT® Membrane: Product Lineup

| Membrane Name | Lead Application / Market | Value |

|---|---|---|

| M775.15 | Commercial vehicle and other heavy-duty applications | High chemical durability & high power density |

| M788.12 | Automotive, back-up power, range extender, fork-lift and portable | High mechanical durability & low gas permeance & cost-effective |

| M765.08 | Passenger vehicle | High power density under dry condition & cost-effective |

| M665.12 | Stable power generation | High chemical and mechanical durability |

Featured Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 542 2624

Have questions or unique requirements?

Our experts are here to guide you.