Filtration & Purification

Protect people, products, and the environment—Gore’s filtration solutions ensure emissions control, process purity, higher yields, and cost efficiency.

Image

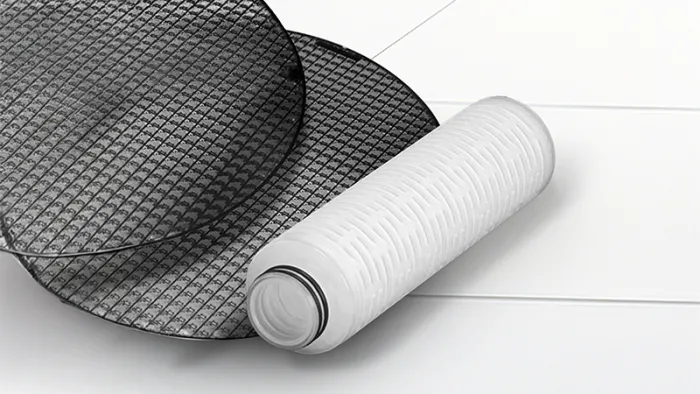

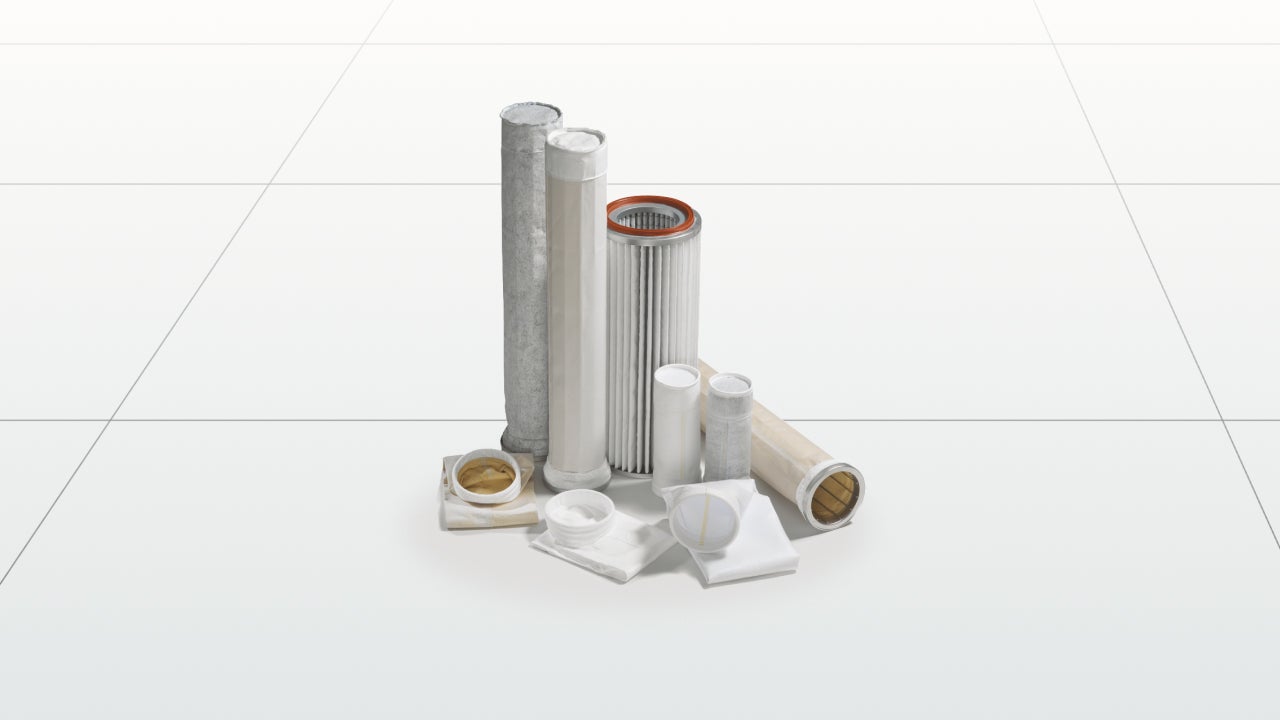

Advance Filtration for Superior Emissions and Contamination Control

Manufacturers across industries must control contamination—whether protecting the environment, ensuring clean pharmaceutical processes, or containing harmful chemicals. With stricter regulations, contamination control is essential for environmental and legal compliance. Gore’s advanced filtration solutions efficiently reduce emissions, remove impurities, enhance productivity, and reduce costs. Built with durable, chemically inert ePTFE, our filters perform reliably in harsh conditions across industries.

Image