GORE-FLIGHT® Microwave Airframe Assemblies

Our lightweight, rugged airframe assemblies offer more protection, reliable signals with low insertion loss, less downtime and lower ownership cost.

Lightweight Solution with Lowest Insertion Loss Before & After Installation

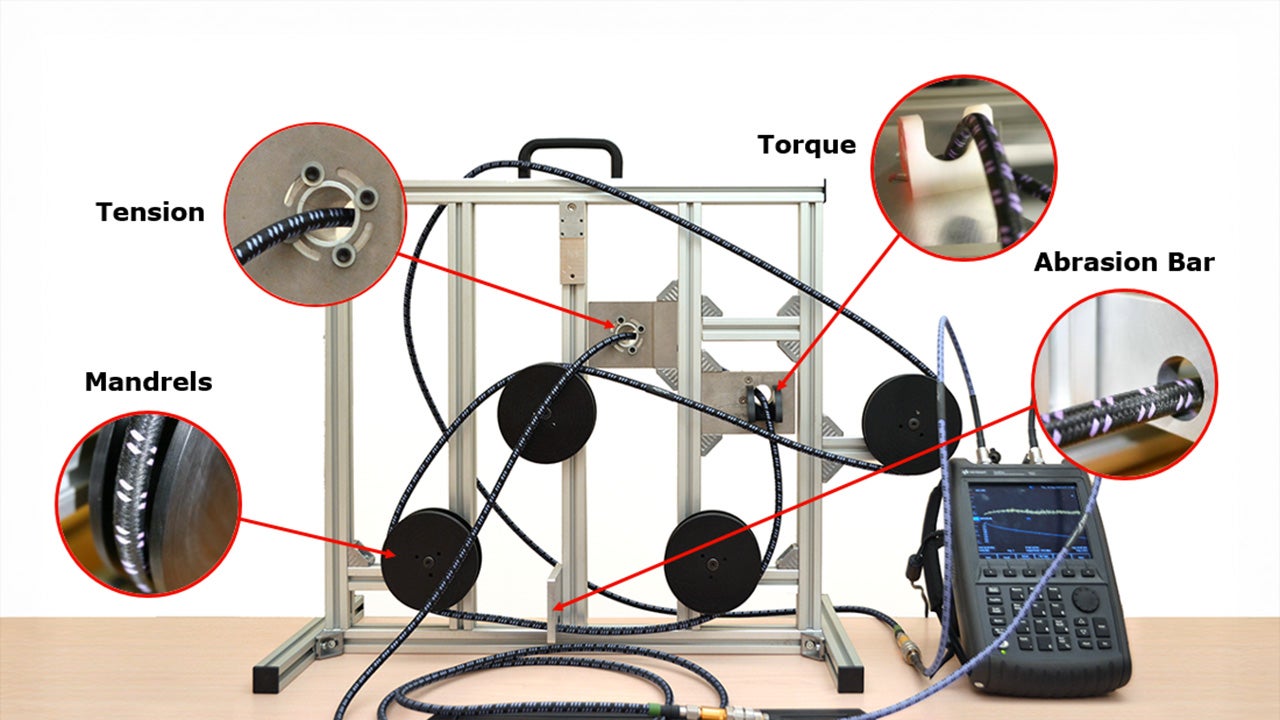

GORE-FLIGHT® Microwave Assemblies are proven to deliver the lowest insertion loss and more reliable VSWR after installation compared to leading competitor assemblies. Our rugged, flexible airframe assemblies can easily withstand rigorous routing, maintenance activities and flight conditions for lifetime performance.

Technical Information

These values demonstrate the electrical, mechanical and environmental performance of GORE-FLIGHT Microwave Assemblies for defense and civil aircraft.

Elec./Mech./Environ. Property

| Value | |||

|---|---|---|---|---|

Type 04 | Type 65 | Type 6E | Type 6G | |

Maximum Frequency GHz | 18 | 18 | 18 | 40 |

Typical VSWR through Max Frequency (straight connector) | 1.25:1 | 1.25:1 | 1.25:1 | 1.30:1 |

Guaranteed VSWR through Max Frequency (straight connector) | 1.40:1 | 1.40:1 | 1.40:1 | 1.45:1 |

Typical Insertion Loss at Max Frequency dB/ft. | 0.633 | 0.342 | 0.198 | 0.795 |

Guaranteed Insertion Loss at Max Frequency dB/ft. | 0.673 | 0.384 | 0.208 | 0.870 |

Standard Impedance Ohms | 50 ± 1 | 50 ± 1 | 50 ± 1 | 50 ± 1 |

Nominal Dielectric Constant | 1.40 | 1.35 | 1.35 | 1.40 |

Nominal Velocity of Propagation % | 85 | 86 | 86 | 85 |

Nominal Time Delay ns/in (ns/cm) | 0.103 (0.04) | 0.0984 (0.0387) | 0.0984 (0.0387) | 0.103 (0.04) |

Shielding Effectiveness through 18 GHz dB | > 90 | > 90 | > 90 | > 90 |

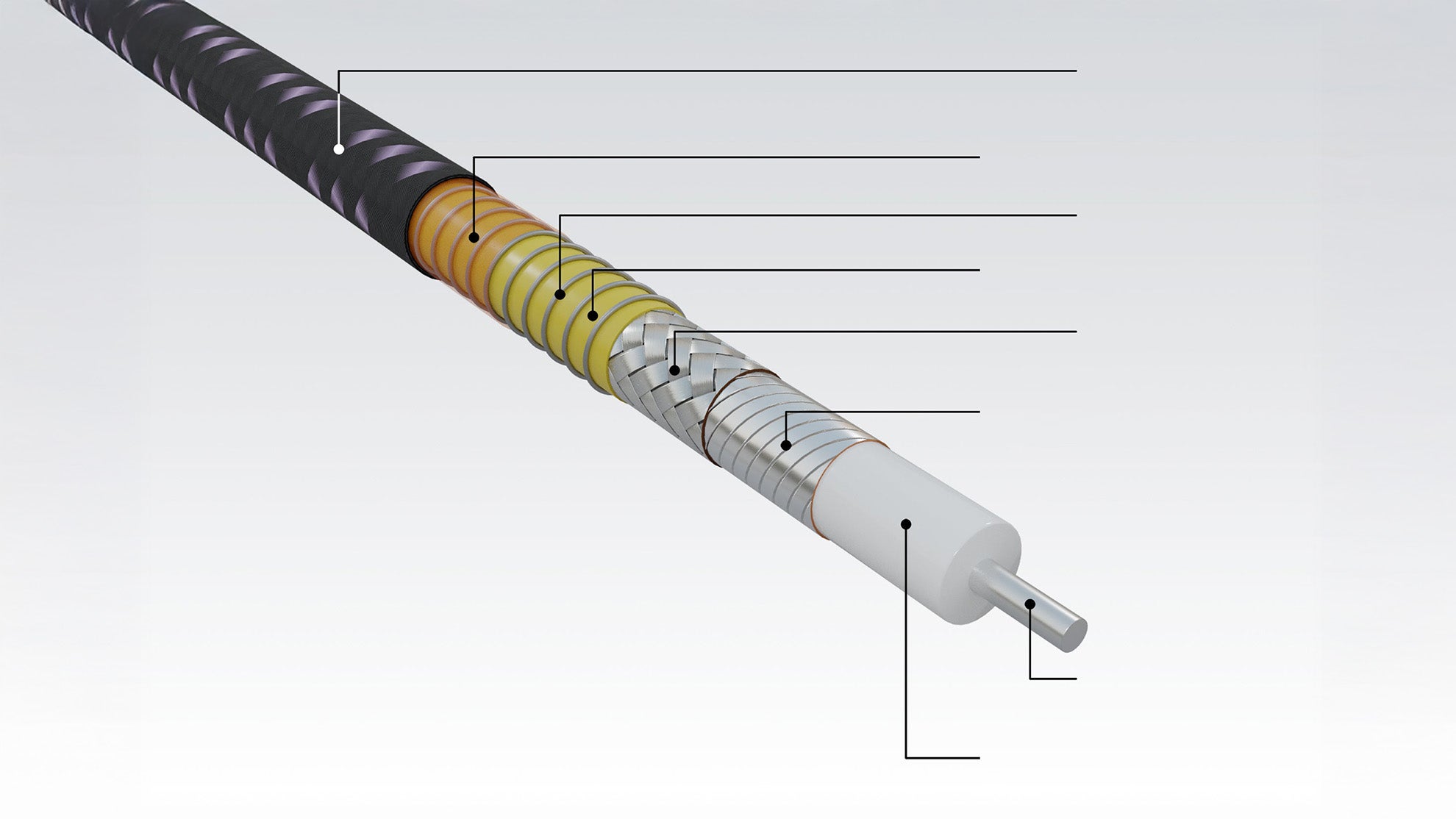

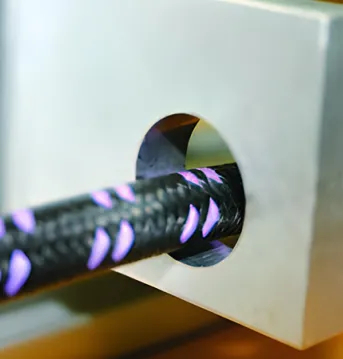

Jacket Material | Braided Engineered Fluoropolymer | Braided Engineered Fluoropolymer | Braided Engineered Fluoropolymer | Braided Engineered Fluoropolymer |

Jacket Color | Black with Purple Stripes | Black with Purple Stripes | Black with Purple Stripes | Black with Purple Stripes |

Center Conductor | Solid Silver-Plated | Solid Silver-Plated | Solid Silver-Plated | Solid Silver-Plated |

Dielectric Material | Expanded PTFE | Expanded PTFE | Expanded PTFE | Expanded PTFE |

Nominal Overall Diameter in (mm) | 0.18 (4.55) | 0.24 (6.1) | 0.35 (8.9) | 0.195 (4.95) |

Nominal Weight lbs./ft. (g/m) | 0.027 (41) | 0.040 (60) | 0.084 (125) | 0.033 (49) |

Minimum Bend Radius in (mm) | 0.5 (12.5) | 1.0 (25.4) | 1.9 (48.3) | 0.75 (19.0) |

Temperature Rangea °C | -55 to +125 | -55 to +125 | -55 to +125 | -55 to +125 |

Concentrated Load lbs. (MIL-T-81490 paragraph 4.7.18) | > 150 | > 150 | > 150 | > 150 |

a. For applications operating outside of these temperatures, contact a Gore representative.

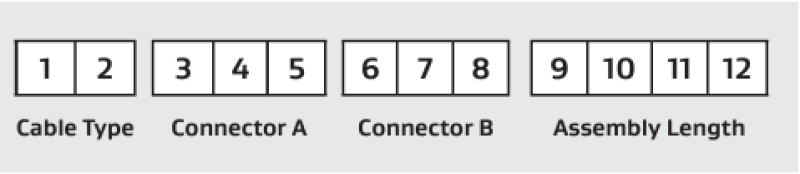

GORE-FLIGHT Microwave Assemblies are identified by a 12-character part number designating the cable type, connector types, and assembly lengths.

Positions 1–2: Two-letter code representing each cable type (e.g., 04, 65, 6E, 6G).

Positions 3–5: Connector A that attaches to the left side of the cable assembly.

Positions 6–8: Connector B that attaches to the right side of the cable assembly.

Positions 9–12: The assembly length is expressed in inches to the nearest tenth, including zeroes to fill positions if the length is less than three digits. For example, the length of a 24-in assembly is specified as 0240 in the last four digits of the part number.

Example part numbers for our cable types include the following:

6EC01C011000

6E8VS90L2500

6E9VL9VL0380

6E9019011680

6E8018012160

6570S70S0360

658VS8522760

6580S7V11320

658VS70S5880

6580S80S4320

Our airframe assemblies are approved for use on the F-16 fighter jet. They can be ordered by the U.S. government and military through the U.S. Defense Logistics Agency’s channels and authorized distributors. Foreign defense engineers, operators or manufacturers can also order our solutions through U.S. Defense Logistics Agency channels.

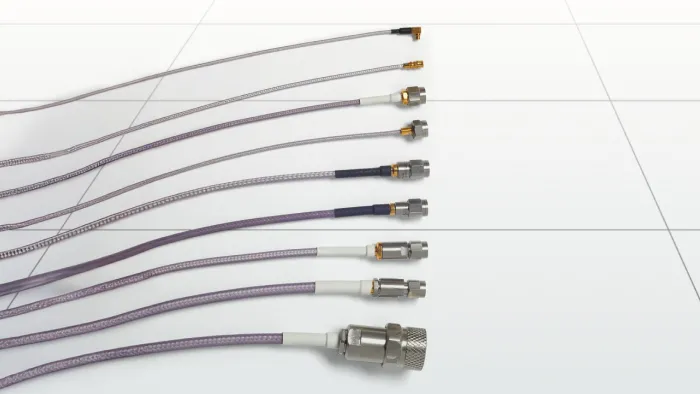

Connector Options

For all of our cable types, we offer a variety of connector options specifically designed to optimize the performance of each assembly, like SMA, TNCA, 2.92 mm and more. We also offer an interface that allows the use of replaceable connectors.

Featured Content

Related Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 866 271 5954

Have questions or unique requirements?

Our experts are here to guide you.